Covalent modification and crosslinking of carbon materials by sulfur addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Solvent-Free Vulcanization of Carbon Nanotube Fibers for Physical Property Improvement

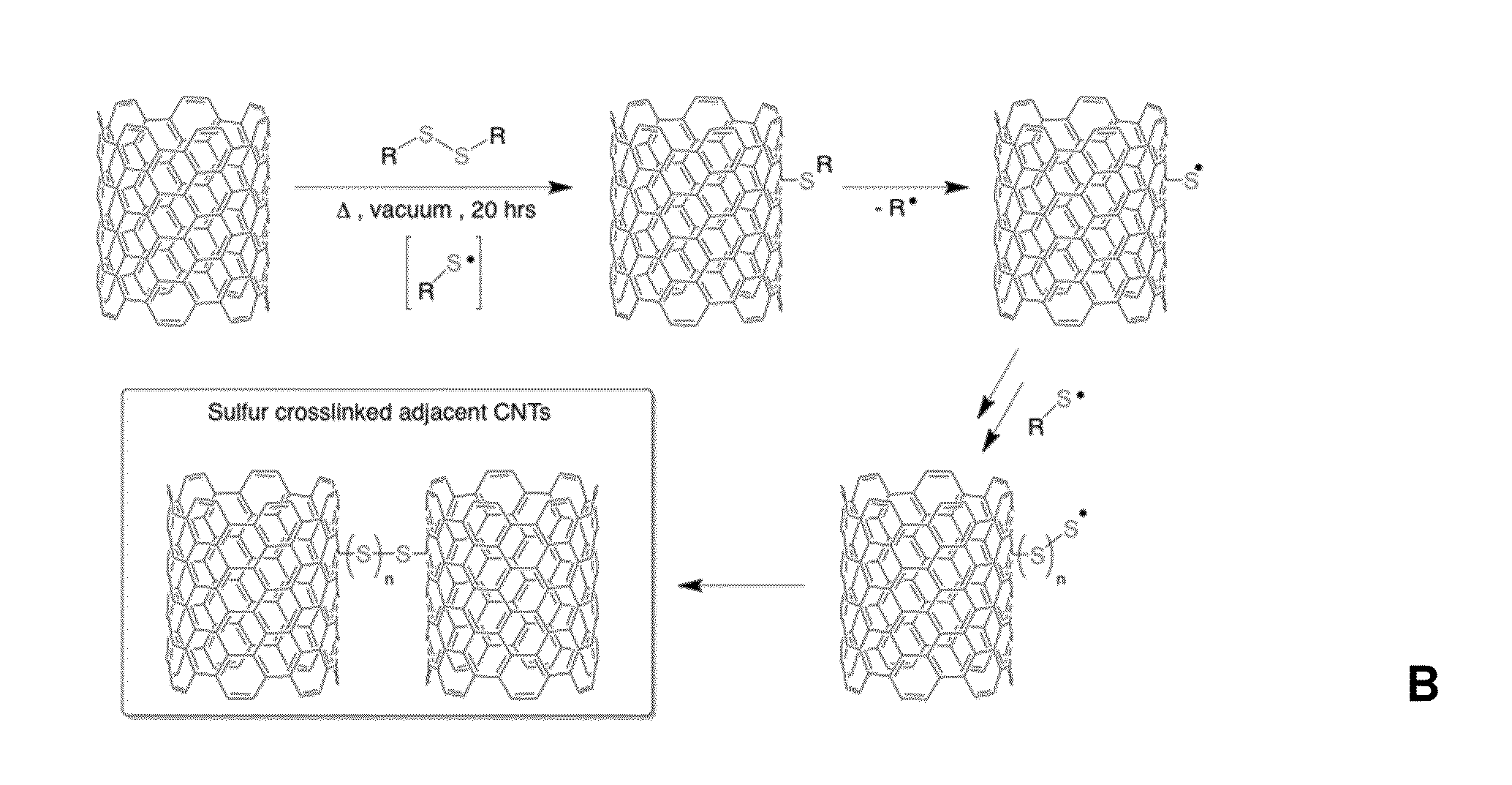

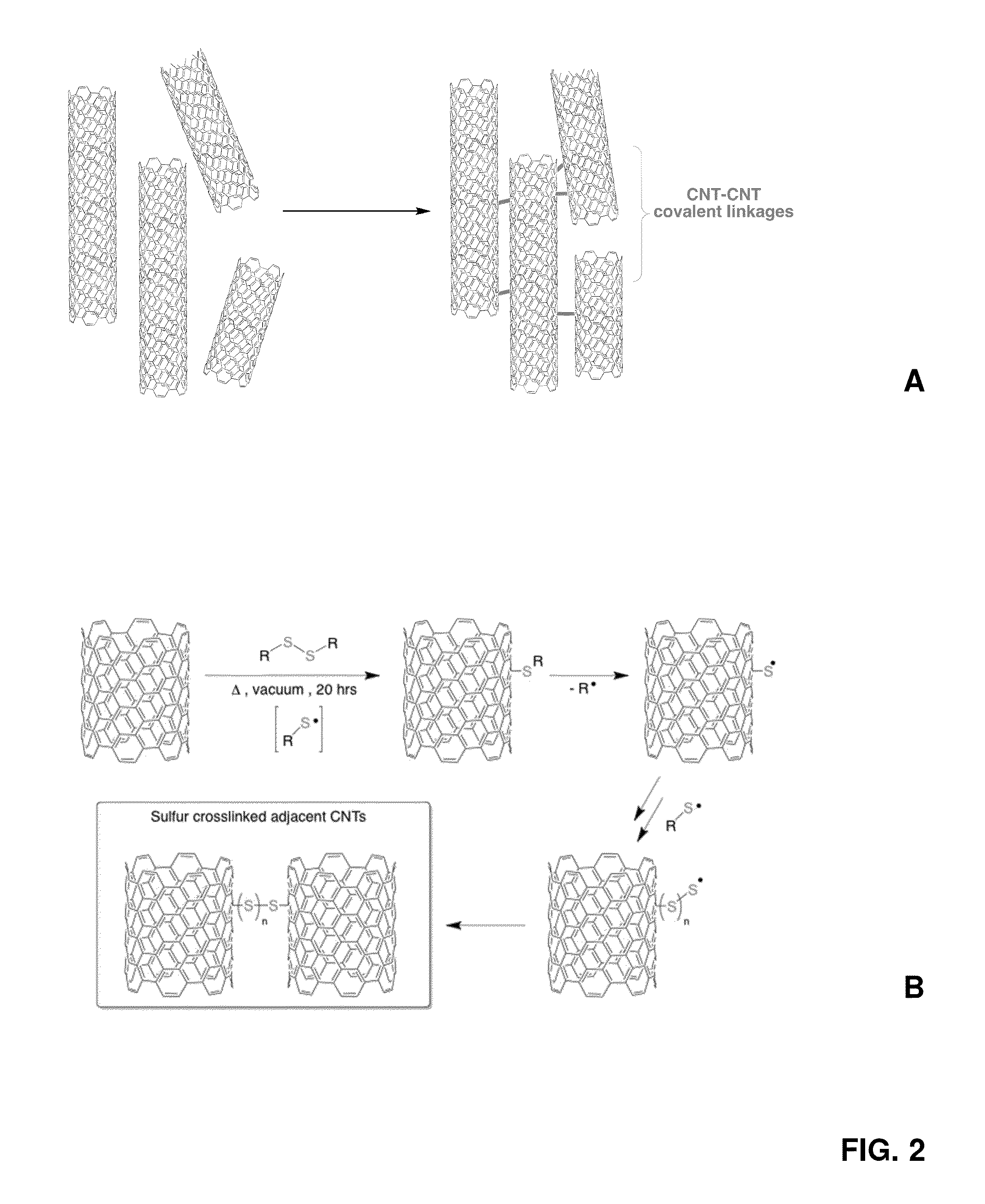

[0068]In this Example, Applicants present a facile method for improvement of the physical properties of carbon nanotube (CNT) fibers. Highly aligned CNT fibers produced via wet spinning were subjected to solvent-free sulfur vulcanization / crosslinking resulting in increased tensile strength and elastic modulus, although electrical conductivity was hampered. Addition of iodine dopant, either concurrent with crosslinking or in an additional step, led to significant improvement in electrical conductivities with no loss in mechanical properties. CNT crosslinking was characterized by Raman spectroscopy, X-ray photoelectron spectroscopy, and effective solubility. Because this crosslinking process is applied to pre-formed fibers, this method is expected to be applicable to CNT / graphene materials created by any process.

[0069]In this Example, Applicants relied on sulfur vulcanization to cross-link CNT fibers...

example 1.1

Materials and Methods

[0080]CNT fibers were manufactured by a reported method (Science, 2013, 339, 182-186) using CNTs (purified grade) purchased from Continental Carbon Nanotechnologies Inc. (Houston, Tex.). Because of variability in fiber batches, all results are normalized to the unprocessed fiber properties from which they derived. All other chemicals were purchased from Sigma Aldrich and used without further purification. Raman spectra of CNT materials were measured using a Renishaw InVia Raman Confocal Raman microscope, with excitation wavelengths of 514, 633, and 785 nm. Scanning electron microscopy (SEM, FEI Quanta 400 ESEM FEG) was used to determine the diameter of the CNT fibers at a magnification of ˜104 for a minimum of 4 segments of a 10-20 mm length of fiber. Mechanical testing of CNT fiber was performed on an Instron model 1000 testing frame with a 5 kg load cell as reported previously.

[0081]The CNT foam was produced by a method to be reported from the same CNT source ...

example 1.2

Protocol for Sulfur Crosslinking

[0082]A length of CNT fiber was attached to a glass support rod by evaporation of a drop of 50% (w / w) sodium silicate solution in water, as a temperature stable and unreactive glue. The other end of the fiber was attached in the same fashion to a glass weight (˜100 mg) to provide tension on the fiber. The glass rod and fiber were added to a glass reaction tube loaded with DTBT (3 mg, 9 μmol). This reactor was fitted with a vacuum adapter sealed with copious vacuum grease. The reaction vessel was evacuated for five minutes and then sealed. The reactor was added upright (taking caution to ensure the fiber was hanging freely and under full tension from the glass weight) to an oven set at 200° C. The reactor was removed after 20 hours, after which the fiber was removed from the reactor, washed with a stream of acetone, and its resistance was measured by four-point probe. Mechanical analysis was performed as described (Science, 2013, 339, 182-186) to deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com