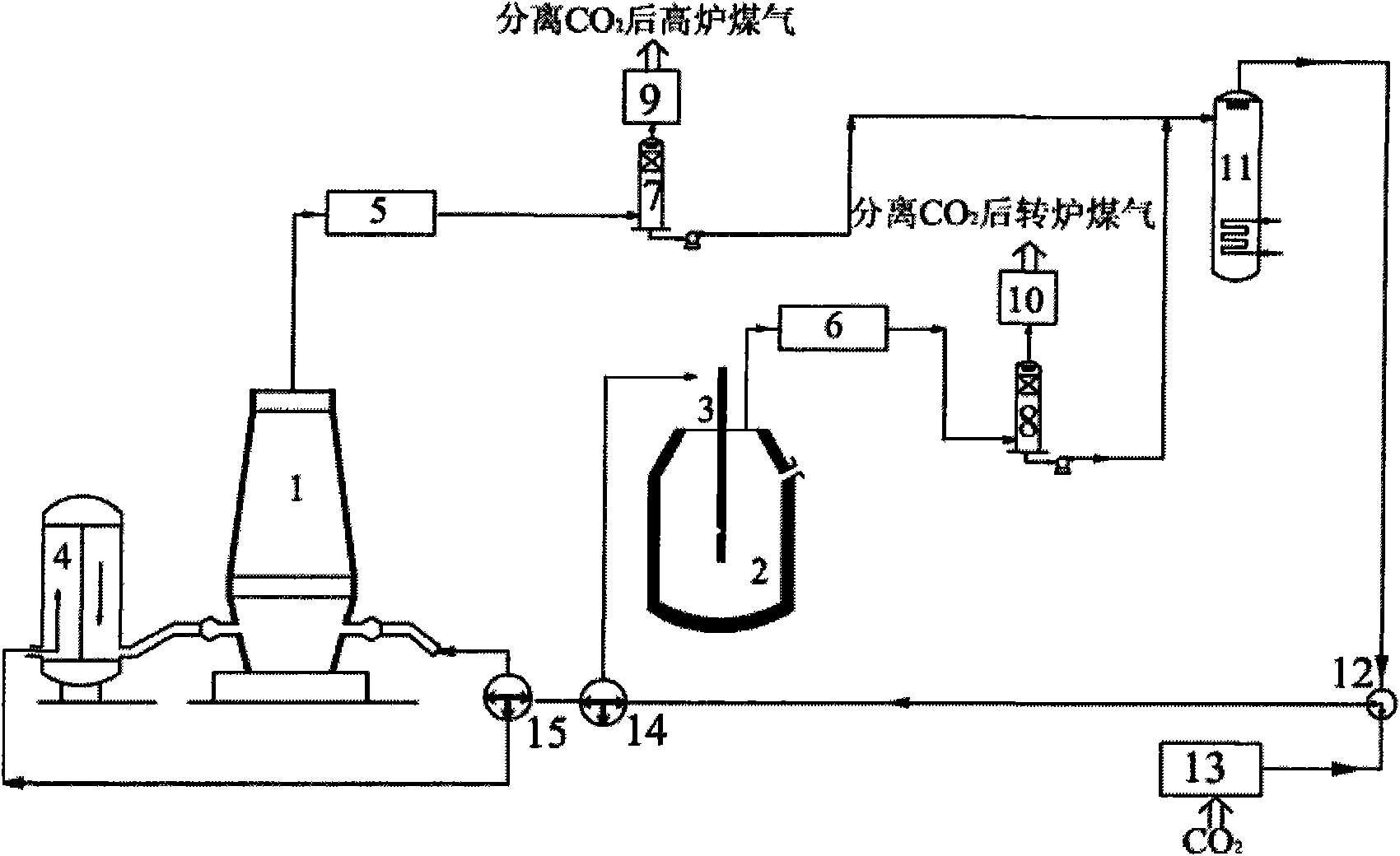

Method for separating, reclaiming and recycling CO2 in gas of blast furnace and converter

A technology for separation and recovery of converter gas, applied in blast furnaces, blast furnace details, furnaces, etc., to achieve the effect of promoting chemical reactions, realizing recycling, and reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. To 2000m 3 The blast furnace and 120t converter slag splash protection process, the adsorption device is used to recover and separate the CO in the blast furnace and converter gas 2 and foreign CO 2 As the carrier gas of blast furnace injection fuel, the gas flow rate is 200~1000m 3 / min, pressure 0.8 ~ 1.5MPa; using this CO 2 Instead of part of the air into the hot blast furnace, the flow rate of cold air is 3500~6000m 3 / min. Adopt this CO 2 Top blowing slag splashing, using the converter oxygen lance to switch and blowing CO into the furnace 2 , the amount of carbon is 30~350kg, and the gas flow rate is 50000~60000Nm 3 / h, the working pressure of the gas is 0.7~0.9MPa.

[0030] 2. To 3200m 3 The blast furnace and 300t converter are protected by slag splashing, and the separated CO is recovered by the adsorption device. 2 As the carrier gas of blast furnace injection fuel, the gas flow rate is 700~1500m 3 / min, pressure 0.2 ~ 1MPa; using this CO 2 Instea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com