Titanium-based bulk amorphous matrix composite and method of fabricating thereof

a technology of amorphous matrix and titanium, which is applied in the field of titanium-based bulk amorphous matrix composite and the field of its fabrication, can solve the problems of lack of reliability and reproducibility of properties of metallic glasses, lack of extended application range of metallic glasses, and intrinsic brittleness of alloys as for oxide glasses, etc., and achieves excellent properties, high mechanical strength, and high hydrogen permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

exemplary embodiment 1

[0082]Amorphous Composite Formation

[0083]The amorphous structure may be formed in several compositions of Ti-alloys such as the binary Ti—Cu and Ti—Ni, ternary Ti—Cu—Zr, Ti—Zr—Ni and Ti—Zr—Be, quaternary Ti—Zr—Cu—Ni and quinary Ti—Zr—Be—Cu—Ni. For the latter, the range of glass formation is quite extended and the maximum size reported so far was about 10 mm diameter. Furthermore, these alloys exhibit interesting properties such as high strength (between about 1.6-2 GPa) and may be deformed with up to about 10% plastic deformation under compression mode at room temperature. The mechanical properties may be further enhanced by the introduction of small sized crystalline phase. The formation of in-situ crystalline phase in the amorphous phase may be achieved by several approaches: the partial crystallization owing to a short-time annealing beyond Tx, phase separation resulting from the immiscibility between two elements, or phase partitioning during cooling. The latter has been applied...

exemplary embodiment 2

[0088]Preparation of the Membrane Alloys

[0089]The bulk metallic glasses and in-situ BMG matrix composites developed for this exemplary embodiment may be prepared by two different techniques: vacuum suction casting and vacuum squeeze casting type techniques.

[0090]Vacuum Suction Casting Technique

[0091]The suction casting technique was used to produce cylinder type rods. FIG. 2A shows a schematic diagram of suction casting apparatus. Pieces of samples were placed on the water cooled copper mold with a small nozzle. The chamber was evacuated and back-filled with a high purity Ar gas. The samples were then remelted and cast into water-cooled copper molds having cylindrical cavities of 10 mm diameter and 50 mm in length or in the form of 12 mm wide, 2 mm thick and 50 mm long plates. Membranes of about 0.5 mm thick were sliced by wire cutting.

[0092]Vacuum Squeeze Casting Technique

[0093]In-situ BMG matrix composite samples were also prepared by vacuum squeeze casting type technique as shown...

exemplary embodiment 3

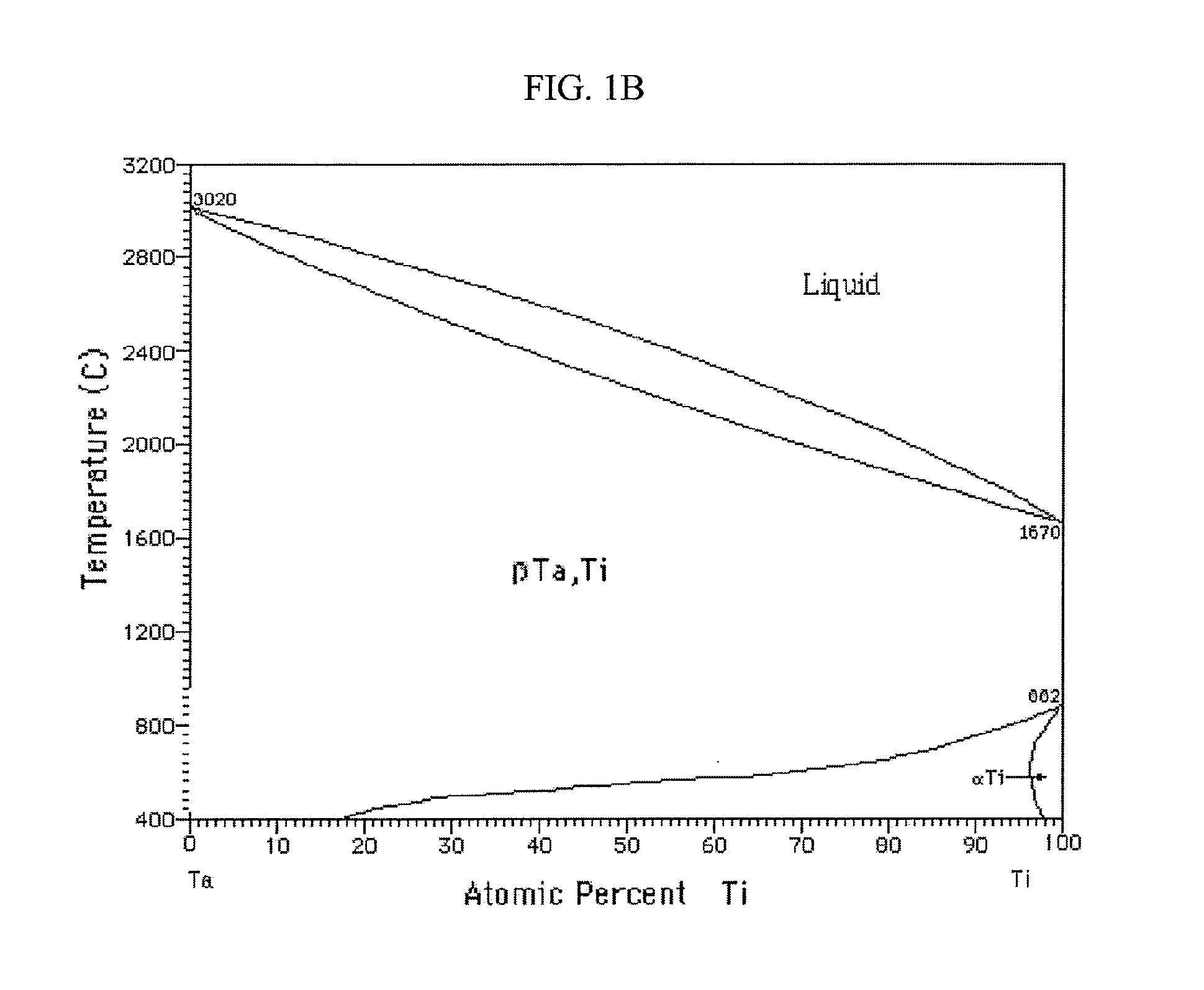

[0094]Structure of Ti—Zr—Be—Cu—Ni—Nb and Ti—Zr—Be—Cu—Ni—Ta Composites

[0095]FIG. 3A shows the XRD traces obtained for the compositions (Ti45Zr16Be20Cu10Ni9)95Nb5 and (Ti45Zr16Be20Cu10Ni9)95Ta5 alloys prepared by suction casting technique in the form of rod of 10 and 7 mm diameter, respectively. The halo peaks indicated that these (Ti45Zr16Be20Cu10Ni9)95Nb5 and (Ti45Zr16Be20Cu10Ni9)95Ta5 rods are fully amorphous in the as-cast state. DSC curves for these compositions are shown in FIG. 3B. Both 10 and 8 mm diameter rods of (Ti45Zr16Be20Cu10Ni9)95Nb5 and (Ti45Zr16Be20Cu10Ni9)95Ta5 compositions exhibit two exothermal peaks about 425 and 525° C., which are corresponding to the amorphous to a metastable crystalline phase and amorphous+metastable phase to Laves phase transformations, respectively.

[0096]These structural and thermal properties of bulk alloy with composition (Ti45Zr16Be20Cu10Ni9)95Nb5 indicated that for this concentration, Nb has little effect on the glass forming ability of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Mechanical strength | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com