Process for surface treatment of metals

a metal surface treatment and metal technology, applied in the direction of detergent compounding agents, boron compounds, inorganic non-surface active detergent compositions, etc., can solve the problems of metal ions released into industrial waste water and/or the environment, damage to equipment, and negative effect of metal surface appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

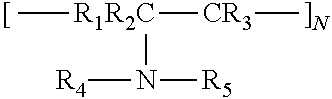

[0027]This invention is directed to an environmentally friendly process for treating metal making use of a formulation which includes sulfuric acid, water and one or more amines or sulfate salts of amines. Sulfuric acid will attack metal surfaces and does so more vigorously at higher concentrations and at elevated temperatures. Even so called inert alloys, such as stainless steel will be attacked by sulfuric acid of the appropriate concentration and temperatures. Addition of amines or amine salts will greatly reduce or eliminate the attack on stainless steel surfaces and will therefore, prevent metals present in these alloys from contaminating wastewater and subsequently the environment.

[0028]This inhibitive effect of amines and amine salts can be seen in Table 1 in which sulfuric acid corrosivity is compared with modified sulfuric acid. In Table 1, the sulfuric acid is modified by the addition of ammonia to the acid. When ammonia is added to sulfuric acid, in general, ammonium hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com