Bioelectrochemical treatment of gaseous byproducts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

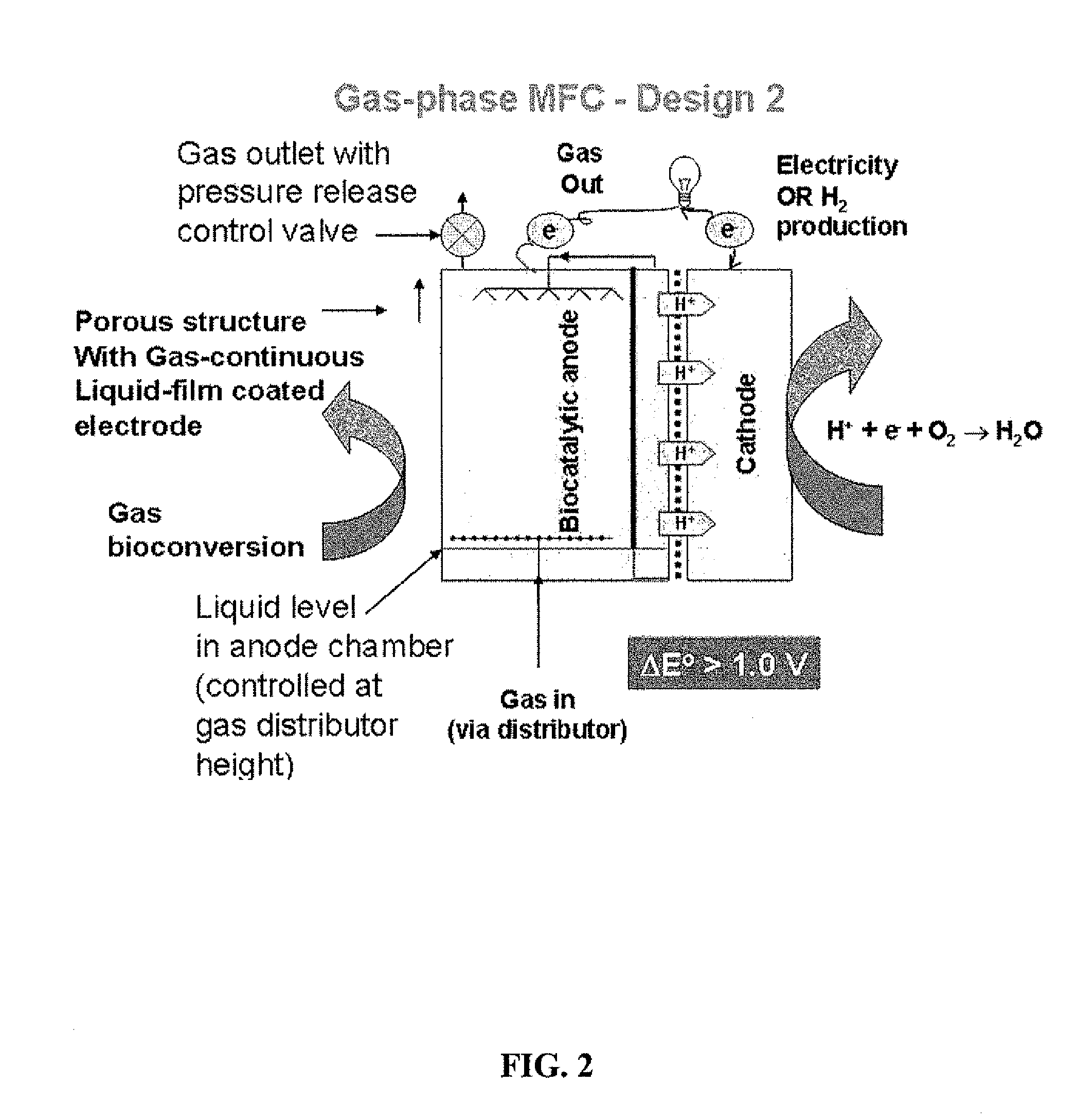

[0020]In one aspect, the invention is directed to a method for removing oxidatively degradable gaseous compounds, such as mercaptan (i.e., thiol) compounds and / or CO, from a gas stream by treatment of the gas stream with one or more BESs. The BES considered herein is any reactor system in which electrons are transferred by microbes to a conductive surface (i.e., by an exoelectrogenic mechanism) during the course of microbial consumption of gaseous byproducts. The transferred electrons are directed to the production of energy, e.g., either electricity or hydrogen production. In a particular embodiment, the BES is a microbial fuel cell (MFC) or microbial electrolytic cell (MEC).

[0021]The method preferably involves flowing a mercaptan- or CO-laden gas stream through a porous anode of the BES, wherein the anode contains microbes residing thereon capable of utilizing the mercaptan compounds or CO as a nutritive and energy source. Catabolism of mercaptan compounds by the microbes results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com