Selective oxidation of propane to propylene oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0048]Two clusters within two spots of 8 mm diameter were deposited on the top of n-doped silicon wafers coated with a thin layer of alumina. The alumina layer, of about 3 monolayer (ML) thickness, was fabricated by atomic layer deposition. The metal loading of the Cu4, Cu12, Cu20, Pd4, Cu4Pd, and Cu3Pd samples was 16.2 ng, 16.2 ng, 16.2 ng, 27.2 ng, 18.4 ng, and 19.00 ng respectively, corresponding to a surface coverage of 10 percent of an atomic monolayer equivalent. This ensures the inter-cluster distance of approximately 5-10 nm and inhibits any sintering occurring during the reaction as the catalyst is heated.

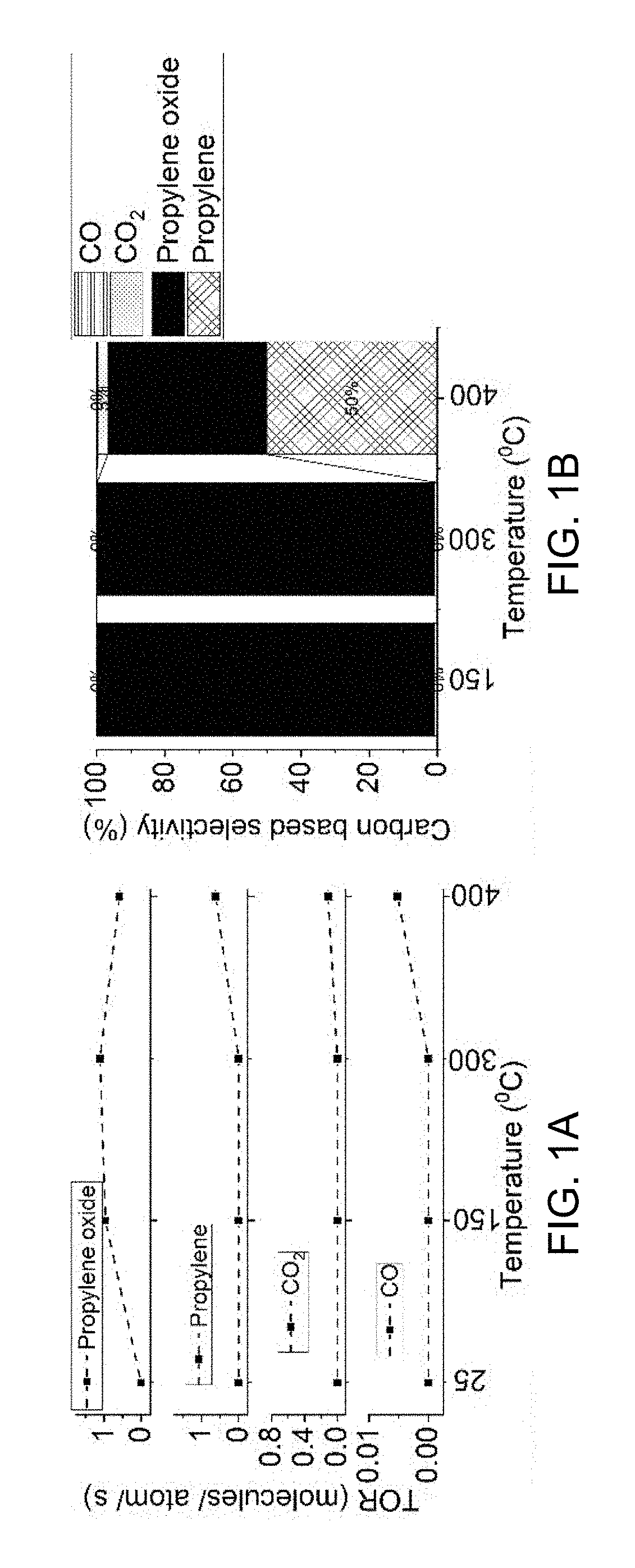

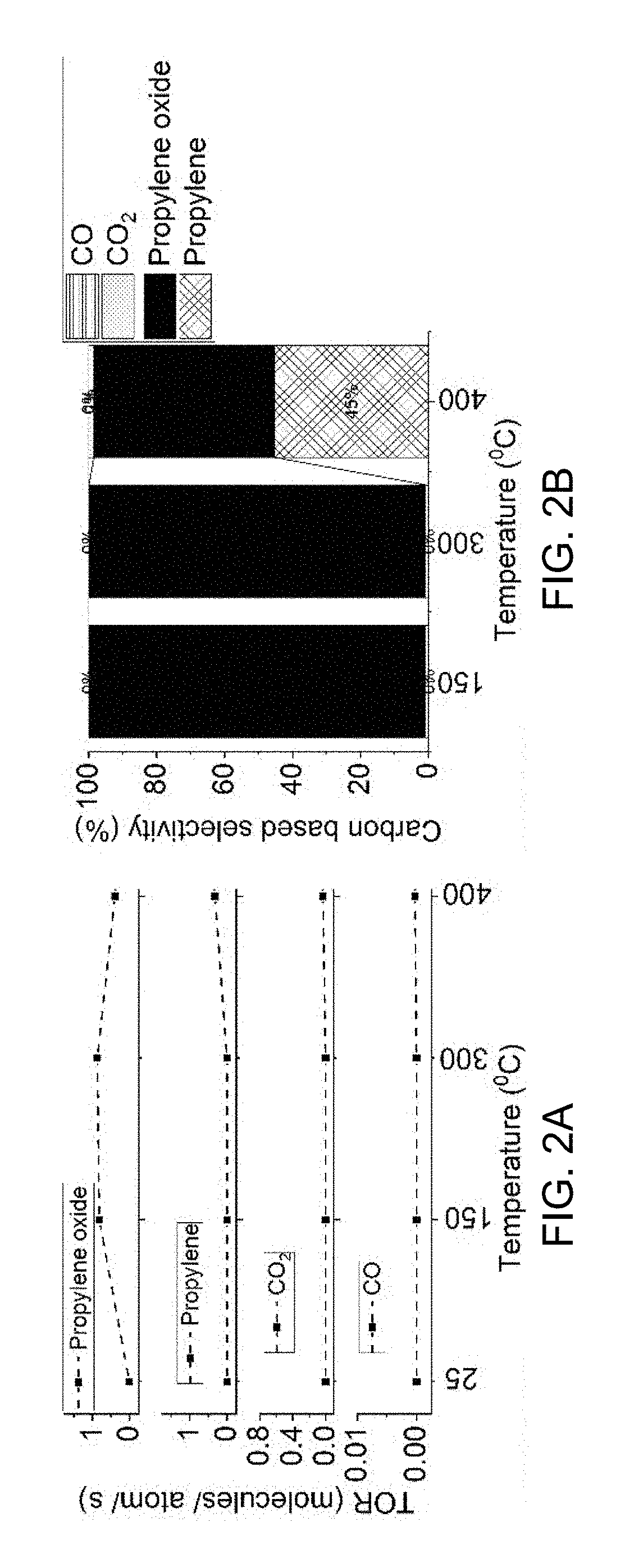

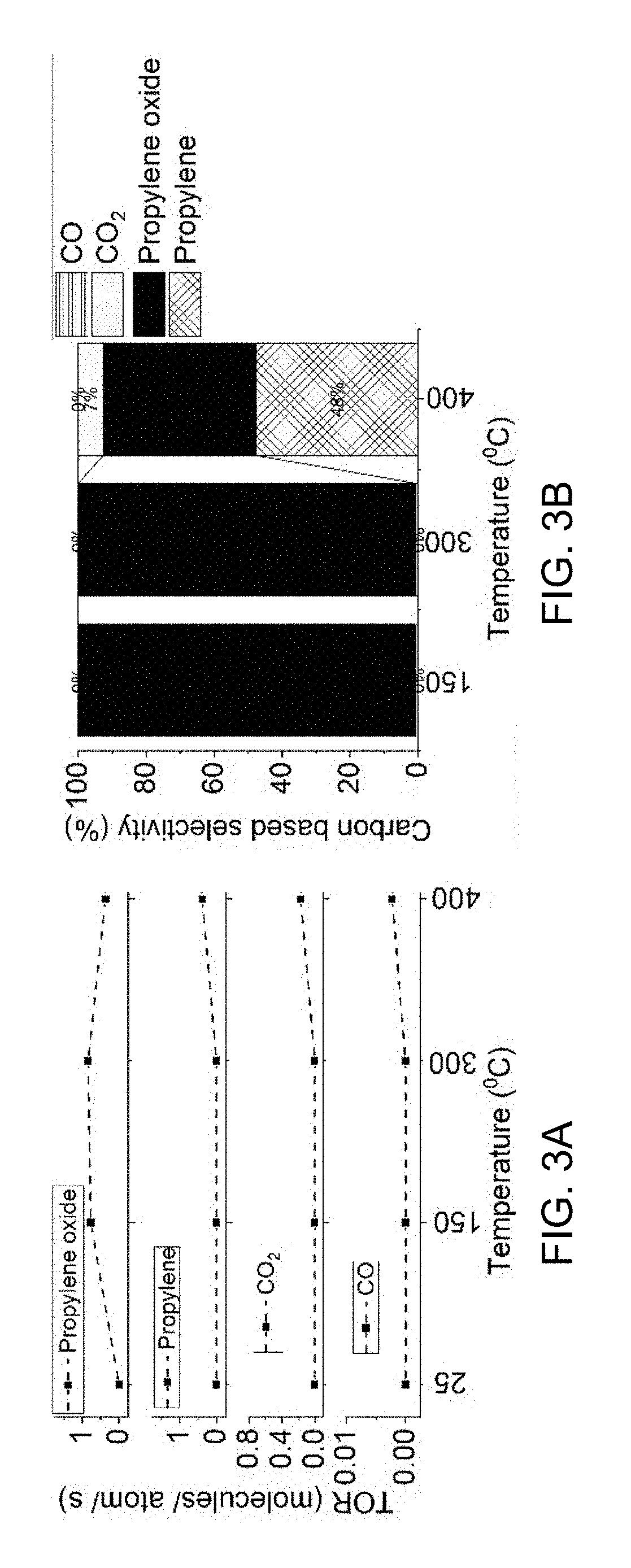

[0049]The reaction was performed in situ with X-ray characterization to simultaneously monitor the reaction products formation on a mass spectrometer, and to monitor the changes in the oxidation state of the clusters during the course of the reaction. The reactor was maintained at a pressure of 800 Torr with a continuous 18.54 sccm flow of 3% O2 and 3% propane mixed in hel...

example 2

[0056]FIGS. 4A, 4B, 5A, 5B, 6A, and 6B depict the formation rate of propylene oxide per metal atom and selectivity on neat 4-atom Pd catalyst clusters (FIGS. 4A-4B) and Cu—Pd catalyst clusters (FIGS. 5A, 5B, 6A, and 6B).

[0057]TOR for propylene, propylene oxide, CO and CO2 are plotted for 4-atom palladium clusters Pd4 (FIG. 4A), 4-atom copper, 1 atom palladium cluster Cu4Pd (FIG. 5A), and 3-atom copper, 1-atom palladium cluster Cu3Pd (FIG. 6A). Carbon based selectivity for the reaction products are plotted for the Pd4 (FIG. 4B), Cu4Pd (FIG. 5B), and the Cu3Pd (FIG. 6B).

[0058]FIGS. 7A-7C is a schematic depiction of the interaction of reagent and product molecules to atoms comprising the catalyst cluster. FIG. 7A shows the propane (in a box) adsorbed onto the catalyst. FIG. 7B shows propylene intermediate adsorbed onto the catalyst. This is a transient condition, with the propylene (showed in a dashed box) converting as it is formed onto the catalyst. FIG. 7C shows propylene oxide prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com