Fe-based amorphous magnetic powder, magnetic powder core with excellent high frequency properties and method of making them

a magnetic powder and high frequency technology, applied in the field of amorphous soft magnetic alloy powder core, can solve the problems of difficult to obtain amorphous alloy powder directly from rapid quenching, low core quality factor, high core loss, etc., and achieve excellent high frequency properties, low oxygen content, and large glass formation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0072]In said embodiment, amorphous Fe72Ni2Al4Sn2P10C2B4Si4 (composition serial number is 1) alloy powder is prepared by water atomization method. The raw materials shall be Fe, Ni, Al, Sn, P—Fe alloy, B—Fe alloy, graphite and Si.

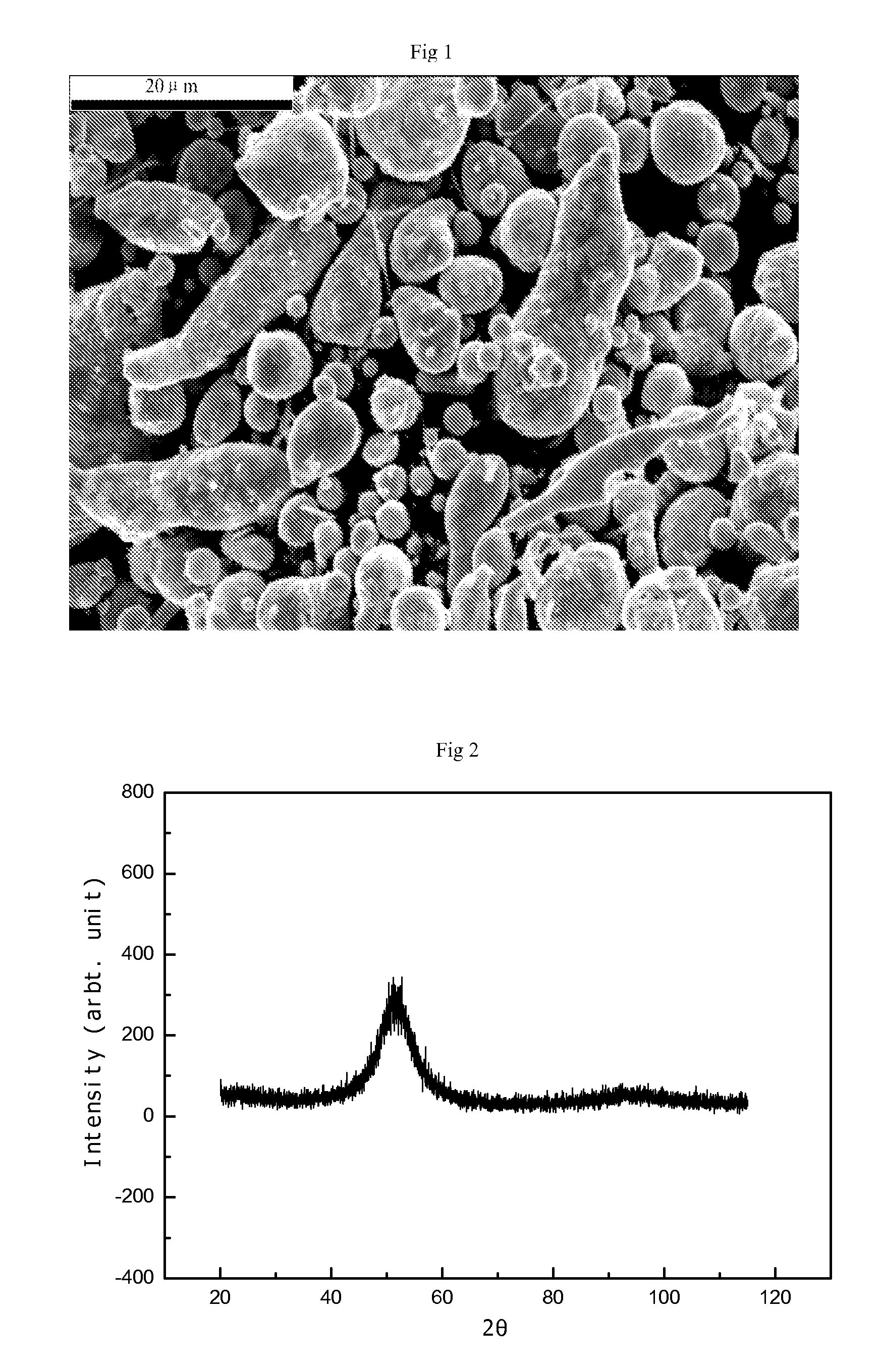

[0073]The morphology of the powder having composition of Fe72Ni2Al4Sn2P10C2B4Si4 is shown in FIG. 1. As shown in this figure, the small particle powder is basically spherical, the big particle powder is elliptical and a small amount of powder is irregular.

[0074]The X-ray diffraction pattern of powder having composition of Fe72Ni2Al4Sn2P10C2B4Si4 is shown in FIG. 2. As shown in this figure, distinct wide atlas exists in X-ray diffraction pattern and there is no notable crystallization peak in it, which indicates that the alloy powder is amorphous. Thereby, Fe72Ni2Al4Sn2P10C2B4Si4 alloy can prepare amorphous alloy powder by water atomization method.

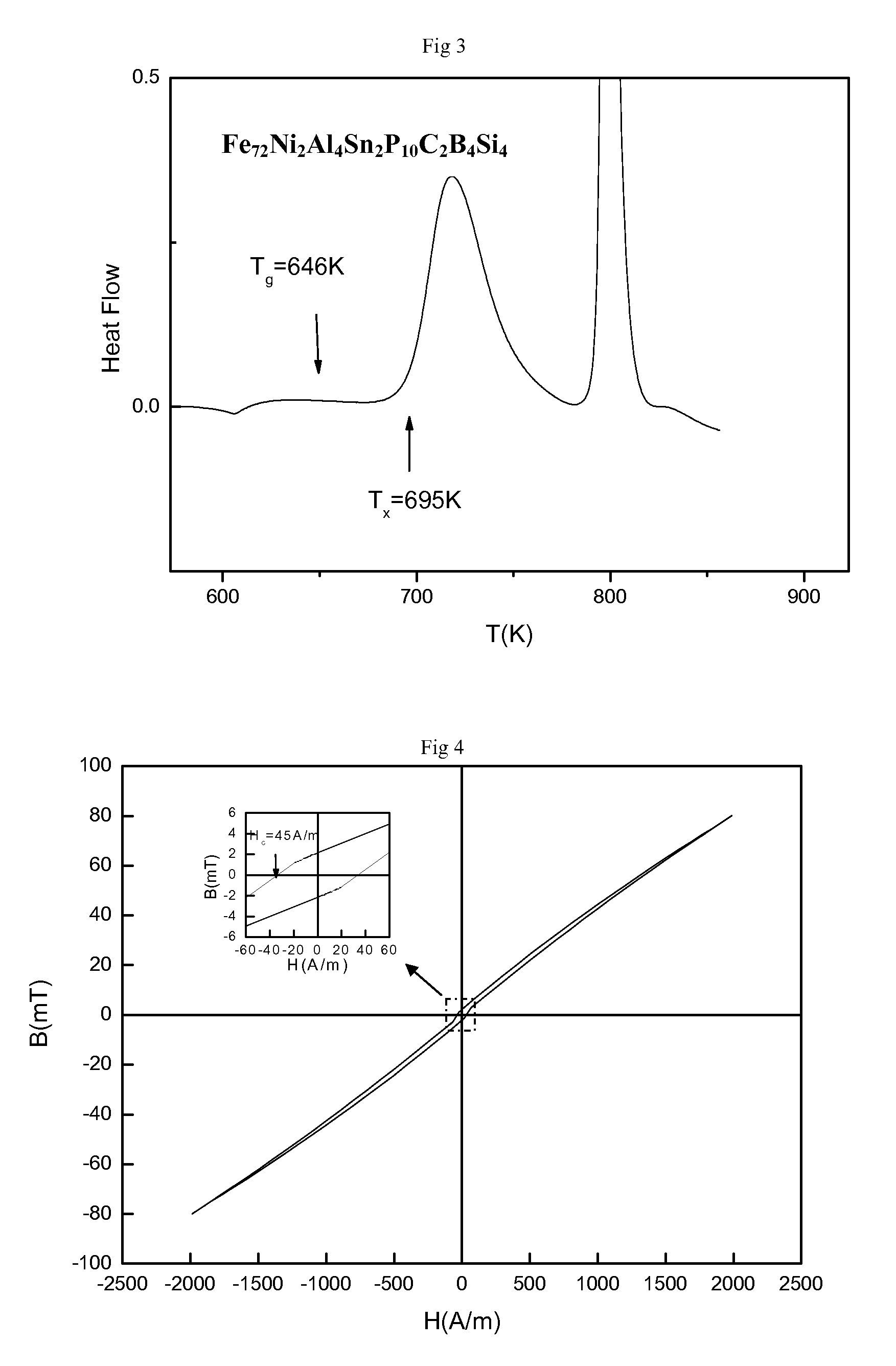

[0075]The DSC thermogram of Fe72Ni2Al4Sn2P10C2B4Si4 powder is shown in FIG. 3. The speed is 10K / minute while per...

embodiment 2

[0081]In said embodiment, amorphous Fe—Ni—Sn—Al—P—C—B—Si series alloy powder is prepared by water atomization method. The raw materials shall select Fe, Ni, Sn, Al, P—Fe alloy, graphite, B—Fe alloy and Si.

[0082]The nominal compositions of said embodiment are listed in Table 1. Glass transition temperature of corresponding alloy, crystallization temperature, melting point, reduced glass transition temperature and width of supercooled liquid region are listed in Table 1 respectively. As seen from this table, except that composition 10 is in a crystallization process, alloy with other composition of said series alloy has high reduced glass transition temperature. The minimum is 0.54 and the maximum is 0.58. The width of supercooled liquid region is over 20K.

TABLE 1Alloy composition in atomicNo.percentageTg / KTx / KTm / KTg / Tm(Tx − Tg) / K1Fe72Ni2Al4Sn2P10C2B4Si464669512090.54492Fe68.5Ni3Al7P11.5C3B565070012090.54503Fe67Ni7Sn2Al4P10B4C2Si465469412080.54404Fe70.5Ni10Sn1Al4P13C2B3Si666569012040....

embodiment 3

[0086]In said embodiment, amorphous Fe—Co—Cr—Sn—Al—P—C—B—Si series alloy powder is prepared by water atomization method. The raw materials are Fe, Co, Cr, Sn, Al, P—Fe alloy, graphite, B—Fe alloy and Si.

[0087]The nominal composition of said embodiment is listed in Table 3. The lists of glass transition temperature of corresponding alloy, crystallization temperature, melting point, approximate glass transition temperature and width of super cooled liquid region are listed in Table 3 respectively. As seen from this table, except that composition 20 cannot be fully formed into amorphous materials, alloy with other compositions all has high reduced glass transition temperature. The minimum is 0.58 and the maximum is 0.60. The width of super cooled liquid region is over 20K.

TABLE 3 3Alloy composition in atomicNo.percentageTg / KTx / KTm / KTg / Tm(Tx − Tg) / K11Fe70Co2Cr2Sn2Al4P10C2B4Si470574412080.583912Fe68.5Co2Cr1Sn2Al7P11.5C3B3Si271574011970.602513Fe68.5Co1Cr5Sn3Al2P11.5C5B2Si271575312230.5838...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercive force Hc | aaaaa | aaaaa |

| Coercive force Hc | aaaaa | aaaaa |

| soft magnetic properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com