Grafted Photo-Polymerized Monolithic Column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

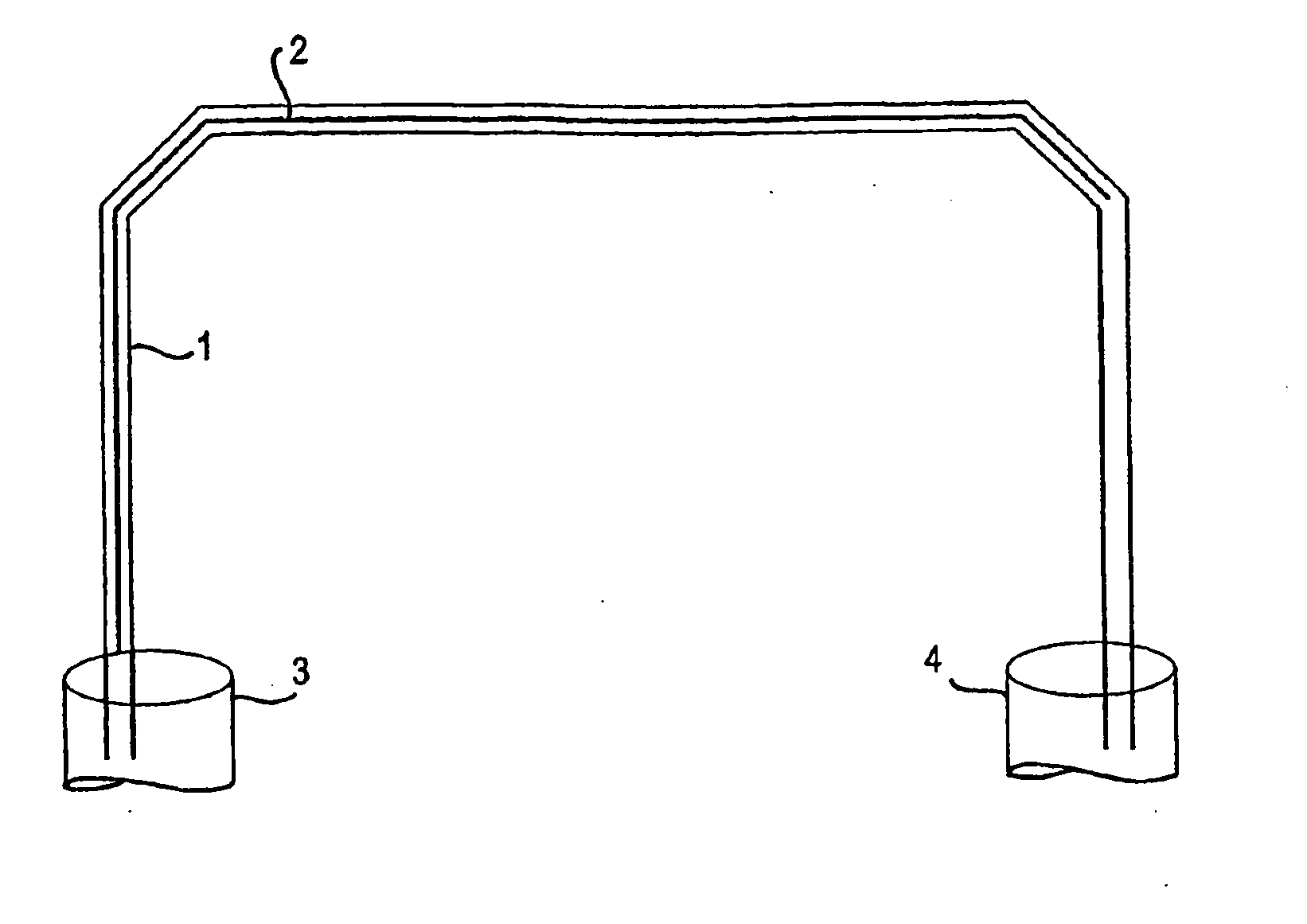

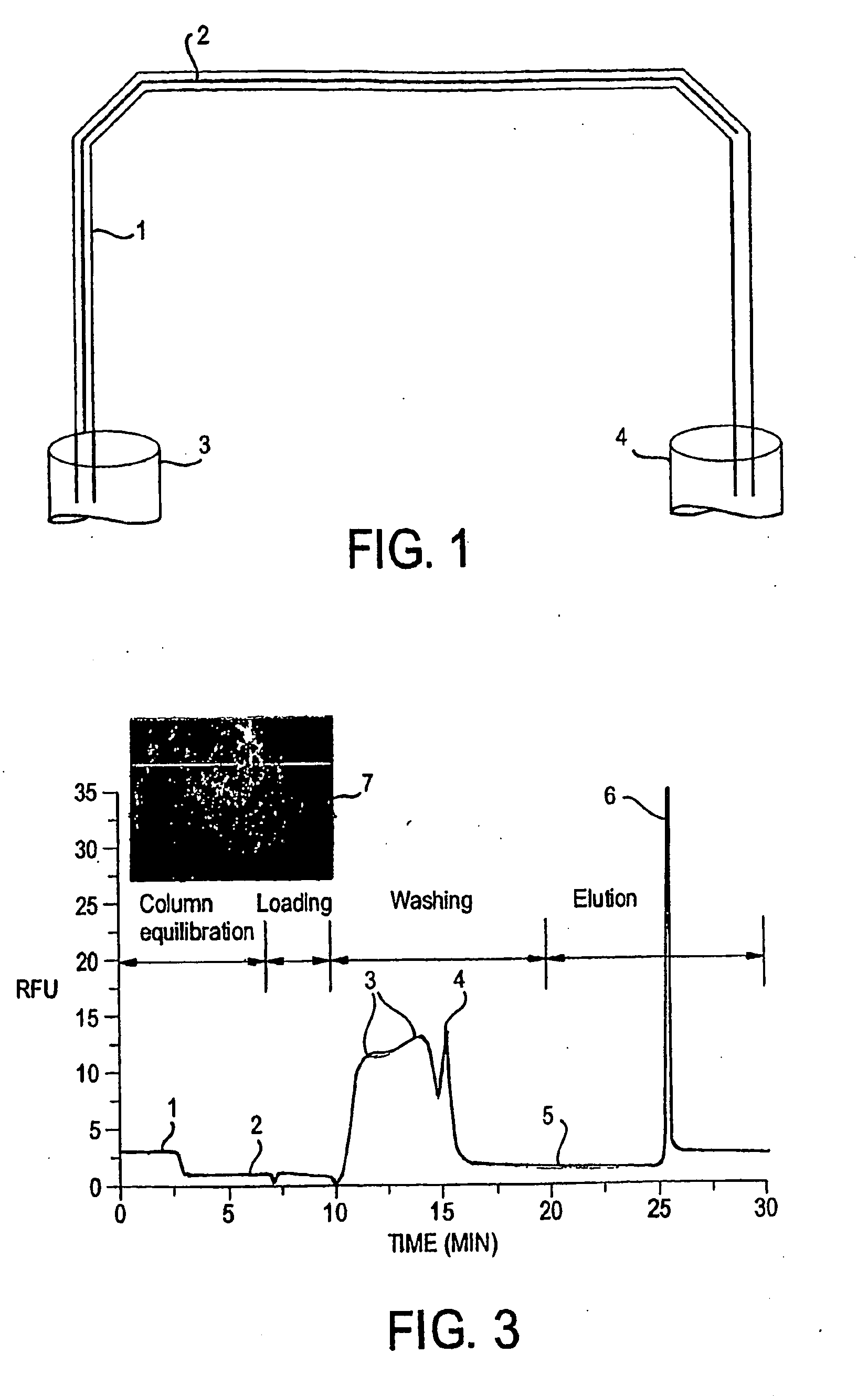

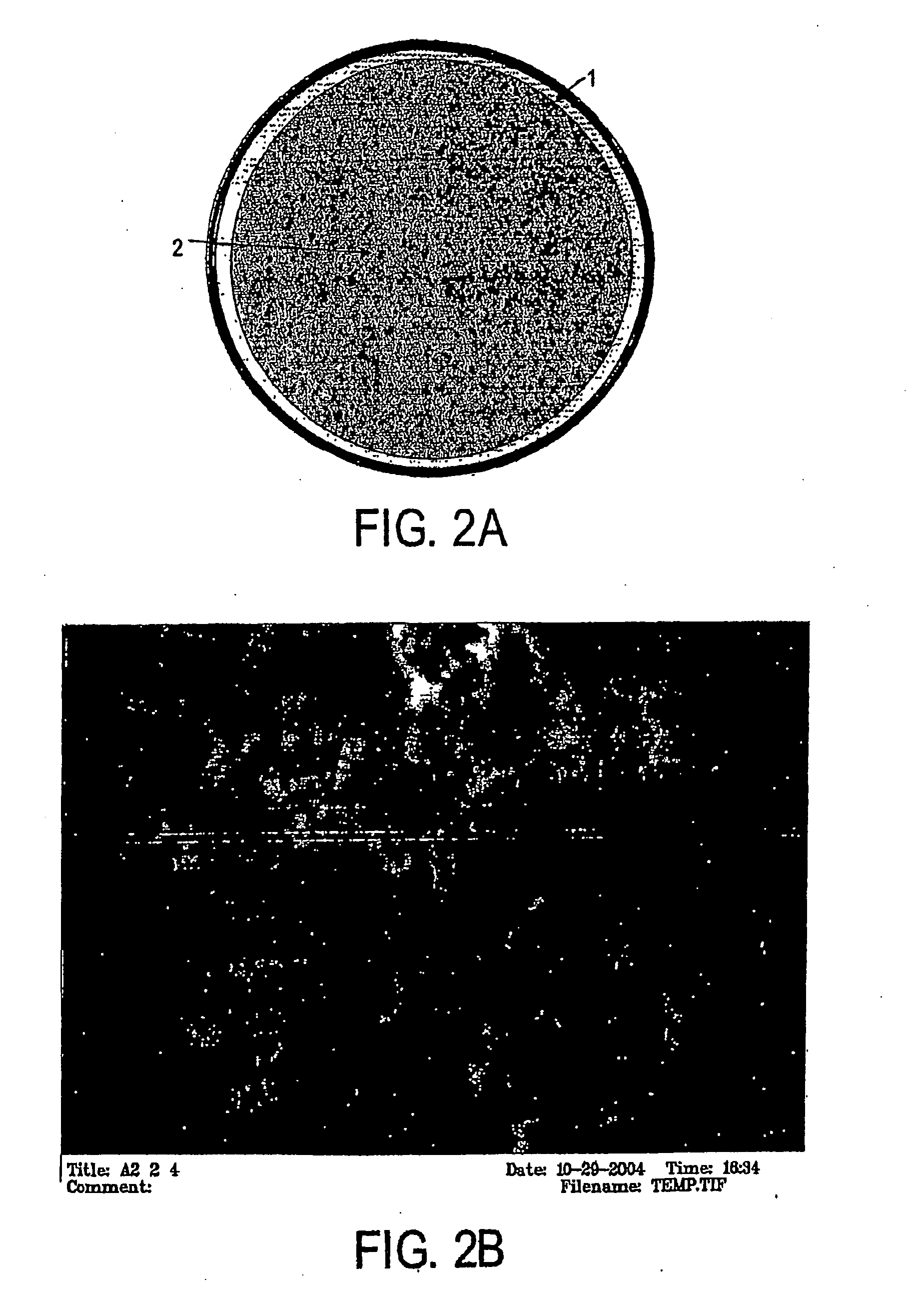

Preparation of Grafted, UV-Photopolymerized Silica-Based Monolithic Column for use in Solid Phase Extraction

[0052]Materials and Reagents. Fused-silica capillary (250 μm i.d.×365 μm o.d.) was purchased from Supelco, Inc. (Bellefonte, Pa.). 3-(Trimethoxysilyl)propyl methacrylate (TMSPM, minimum 98%) and tetramethylorthosilicate (TMOS, 98%) were obtained from Sigma-Aldrich (Milwaukee, Wis.). Toluene (99.9%), 2-propanol (HPLC grade), guanidine hydrochloride (GuHCl, electrophoresis grade), ethanol (95%) and Tris(hydroxymethyl)aminomethane (Tris) were purchased from Fisher Scientific (Fairlawn, N.J.). EDTA was obtained from American Research Products (Solon, Ohio). Photoinitiator Irgacure 1800 was generously donated by Ciba (Tarrytown, N.Y.). All solutions were prepared with nanopure water (Barnstead / Thermolyne, Dubuque, Iowa).

[0053]Labeled DNA Fragment Generation. A 380-bp β-globin DNA fragment was amplified using the polymerase chain reaction (PCR) in a Bio-Rad Mycycle™ Thermal cycler (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com