Plasma actuated electronic catalytic converter

a technology of electronic catalytic converter and actuation mechanism, which is applied in the direction of mechanical equipment, machines/engines, exhaust treatment, etc., can solve the problems of increasing the back-pressure of the exhaust pipe, serious degrading performance, and a plethora of exhaust after-treatment systems devoted to reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082]The invention will now be described in further detail in connection with illustrative preferred embodiments for improving exhaust after-treatment of industrial processes, furnaces, and internal combustion engines. Special attention will be paid to the problems faced in the treatment of exhaust from diesel engines. There will be presented several different variations of each section of the device within the scope of the present invention.

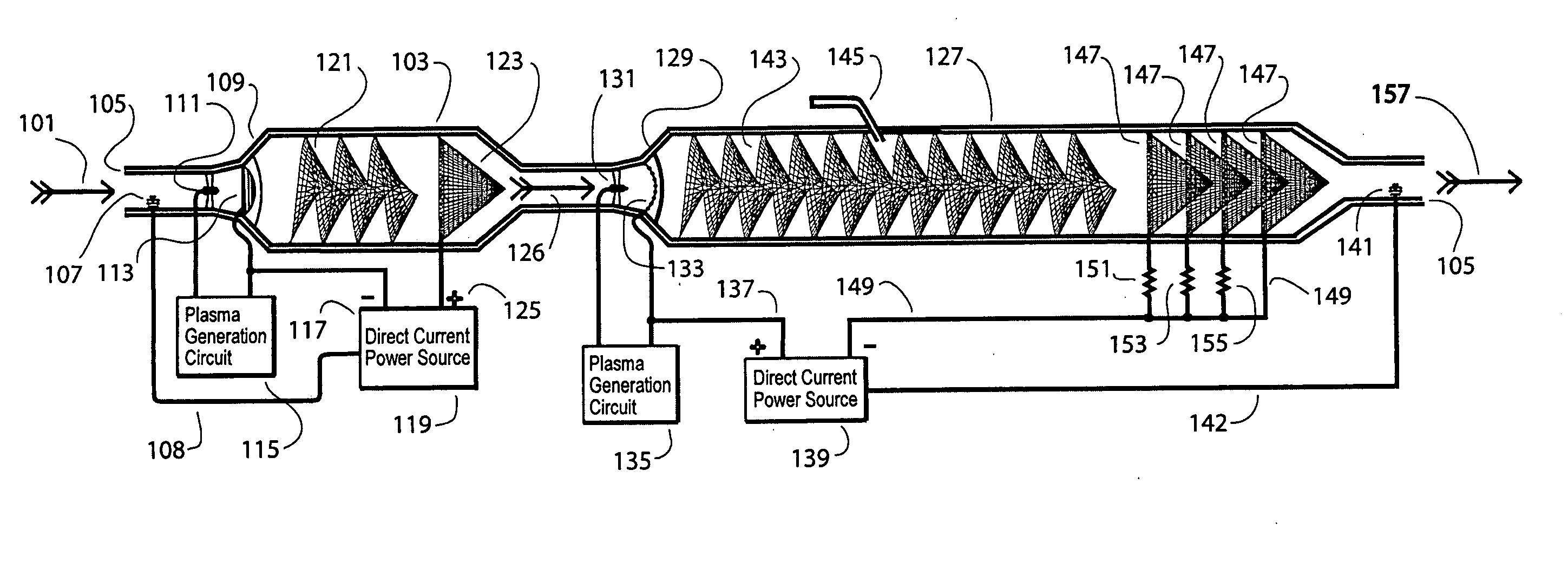

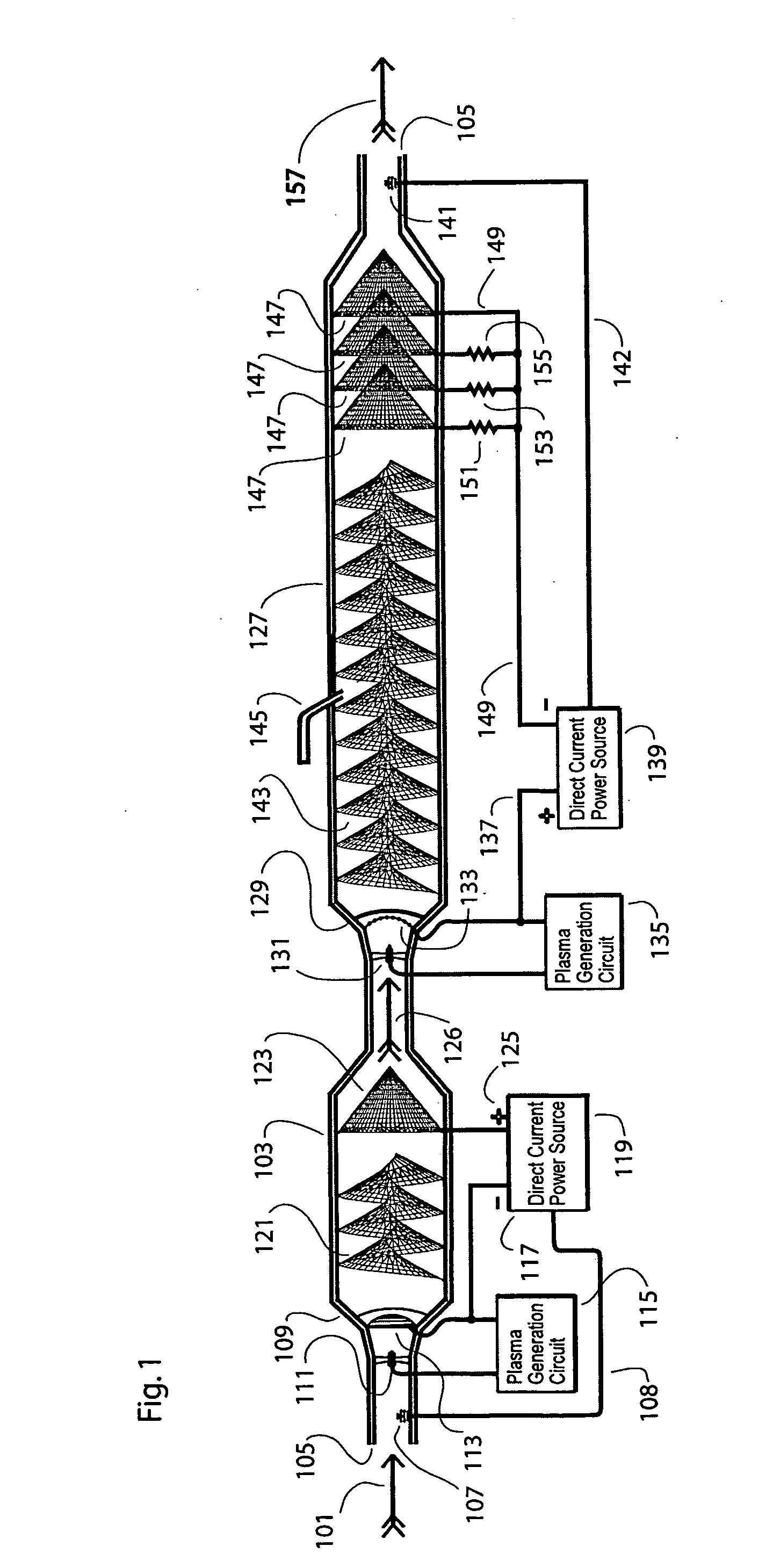

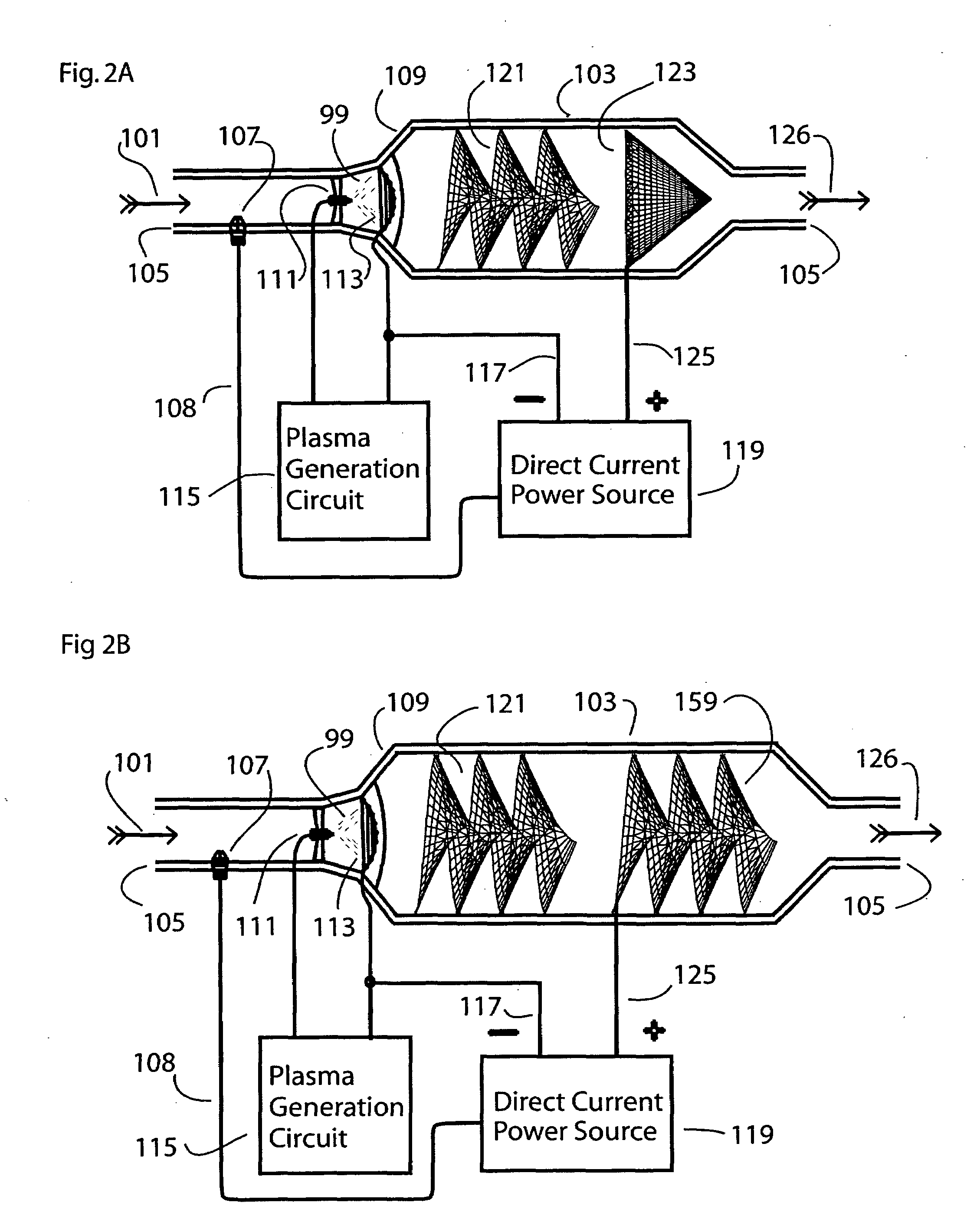

[0083]Referring to FIG. 1, the present invention is shown treating an exhaust output from a diesel engine 101 which enters a plasma oxidization reaction chamber 103 which is enclosed in an electrically insulated outer casing 105. As the gases to be treated flow in the first thing they encounter is a hydrocarbon pollutant level sensor 107 just before they are subjected to the first phase of the treatment process. This process is the ionization and the addition of electrons to the exhaust gases by a plasma discharge anode device 109 which consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com