Fuel filter assembly

a technology of fuel filter and assembly, which is applied in the direction of filtration separation, machine/engine, separation process, etc., to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Referring to the drawings, the present invention will now be described in detail with reference to the preferred embodiment.

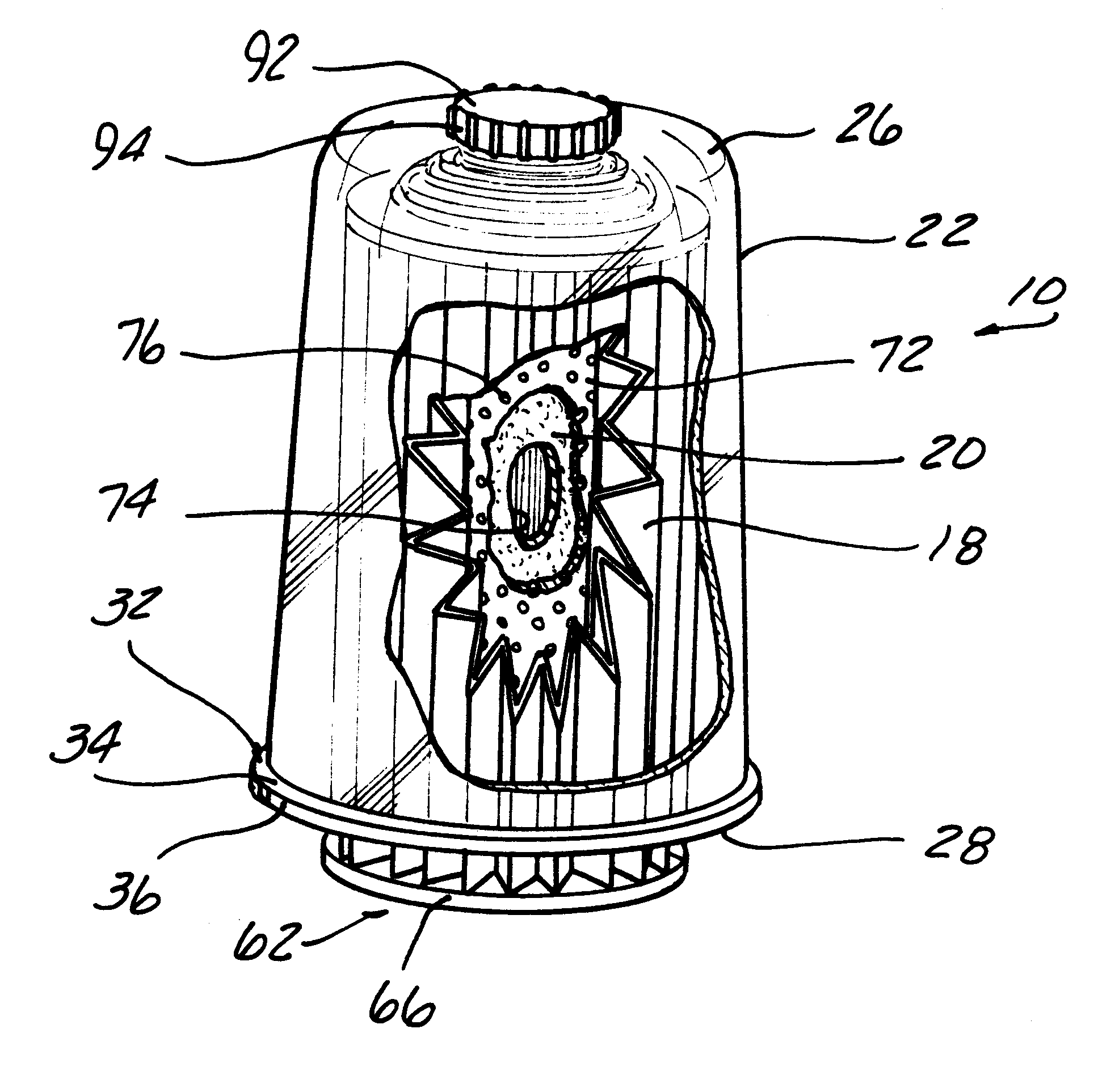

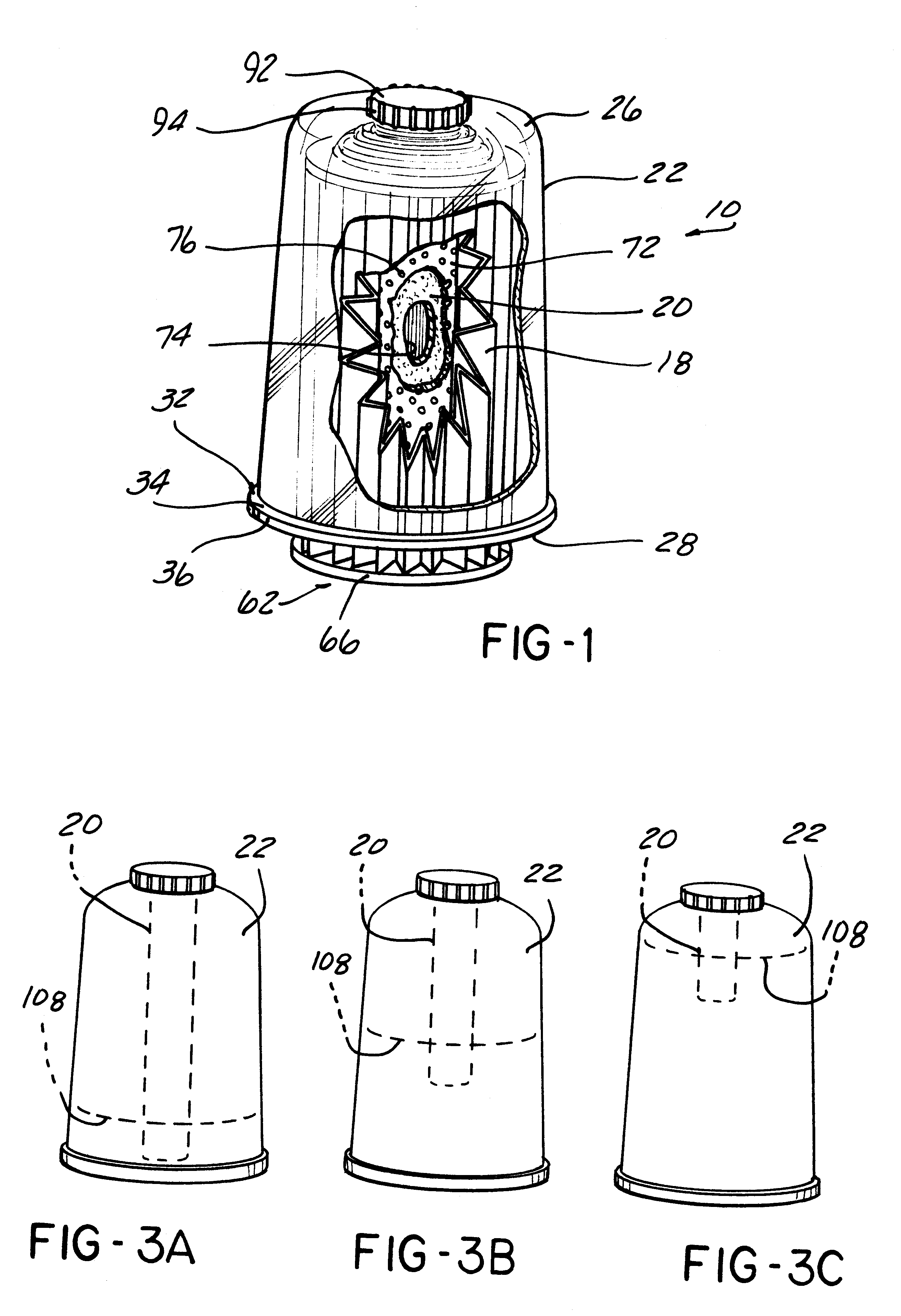

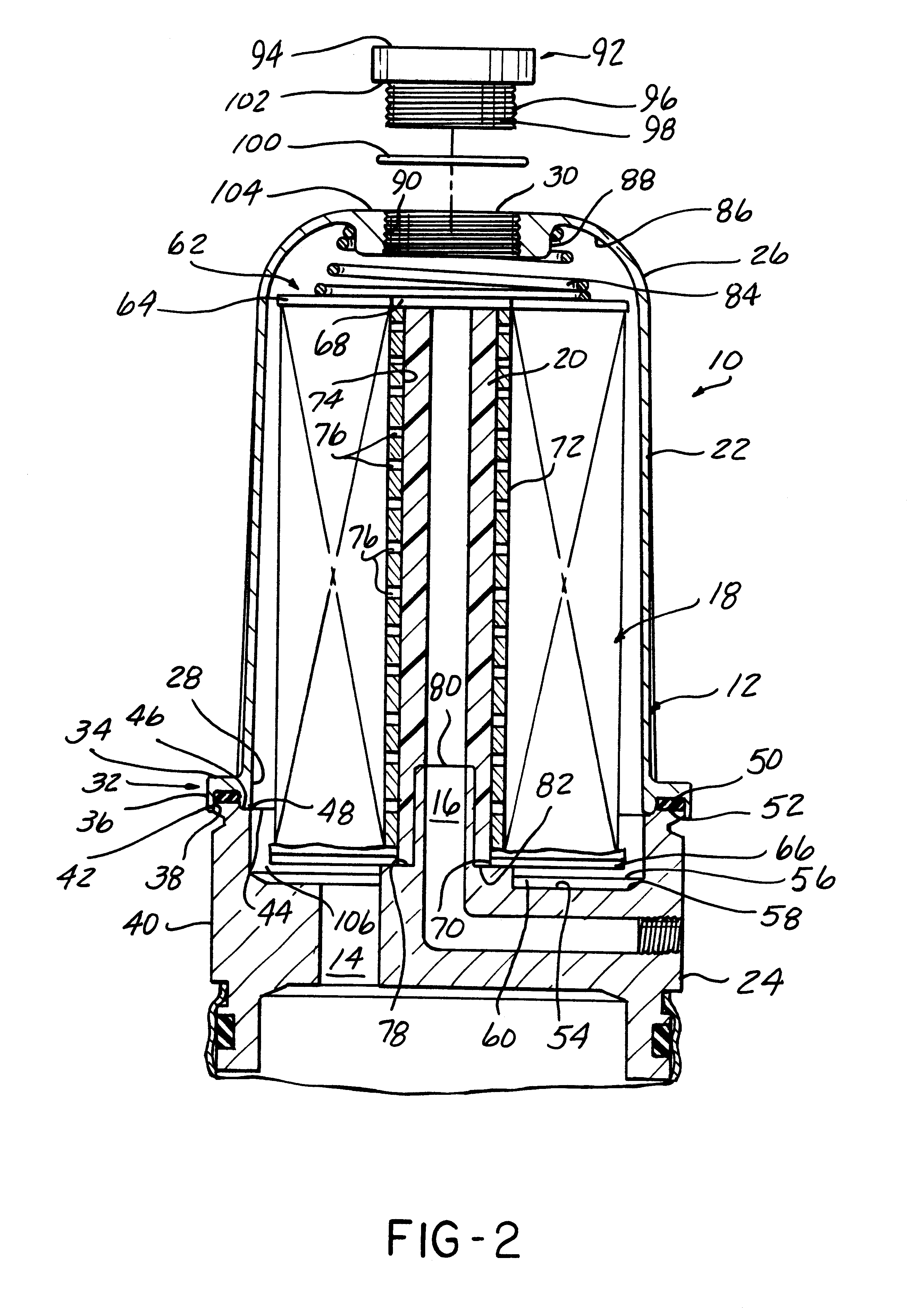

FIGS. 1 and 2 show the fuel filter assembly 10 in its preferred form. The fuel filter assembly 10 is mounted vertically upright and provides a closed housing 12 having a fuel inlet 14 that is in communication with a fuel storage tank (not shown) and a fuel outlet 16 that is in communication with an engine (not shown) of a motor vehicle (not shown). A filter media 18 is housed within the housing 12, and a fuel additive 20 is contained within the filter media 18. The fuel inlet 14 delivers fuel (not shown) into the housing 12 so that the fuel passes through the filter media 18 and contacts the fuel additive 20. The fuel additive 20 is soluble in fuel and dissolves in the fuel. The filtered and treated fuel exits through the fuel outlet 16 and flows to the engine.

To allow for maintenance of the fuel filter assembly 10, a simple means for disassembling and reassemb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| hydrophobic | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com