High Total Transmittance Alumina Discharge Vessels Having Submicron Grain Size

a technology of alumina discharge vessels and total transmittance, which is applied in the manufacture of electric discharge tubes/lamps, electrode systems, manufacturing tools, etc., can solve the problems of low total transmittance and relative population, and achieve the effect of increasing the total transmittance of co-doped alumina ceramics and low total transmittan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

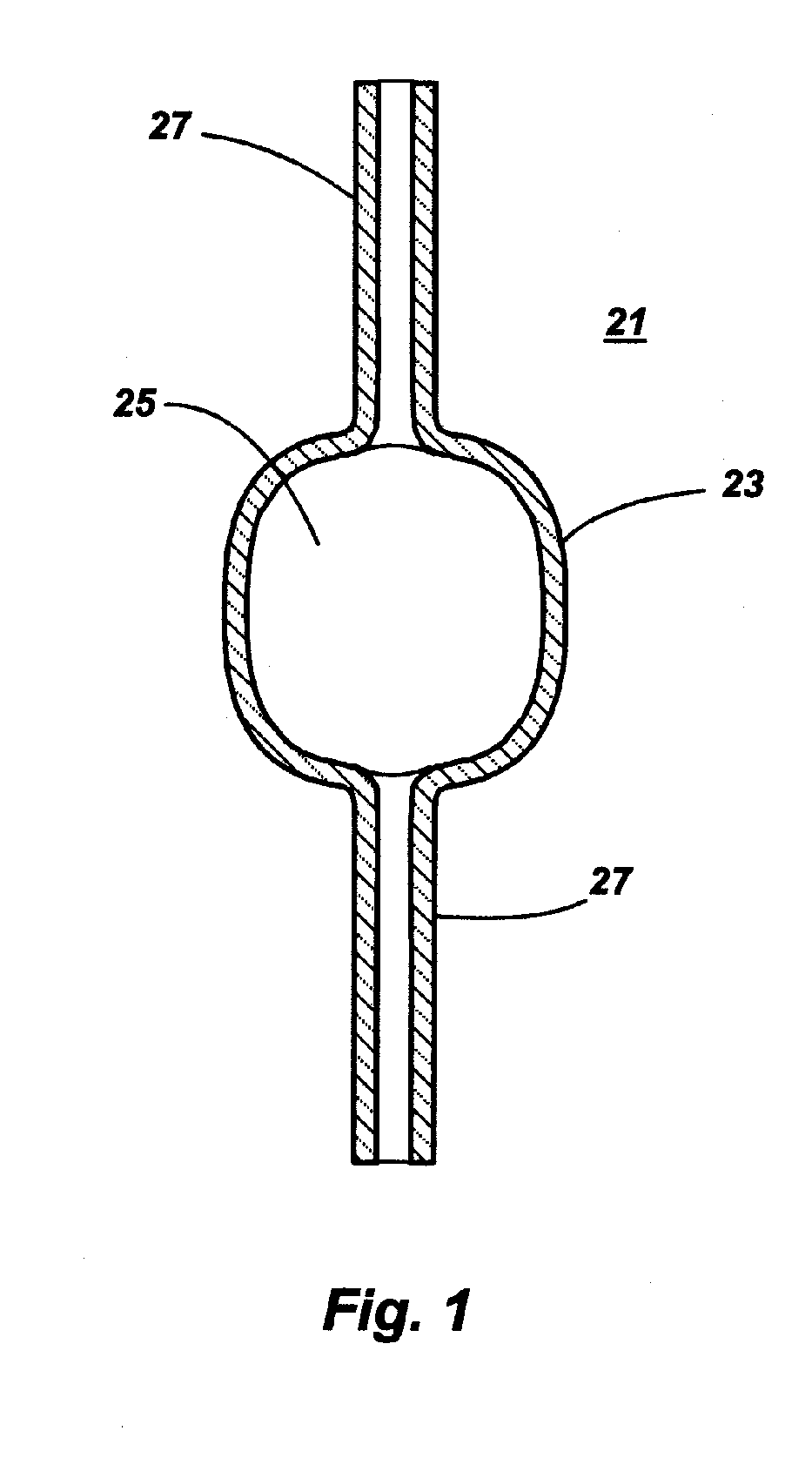

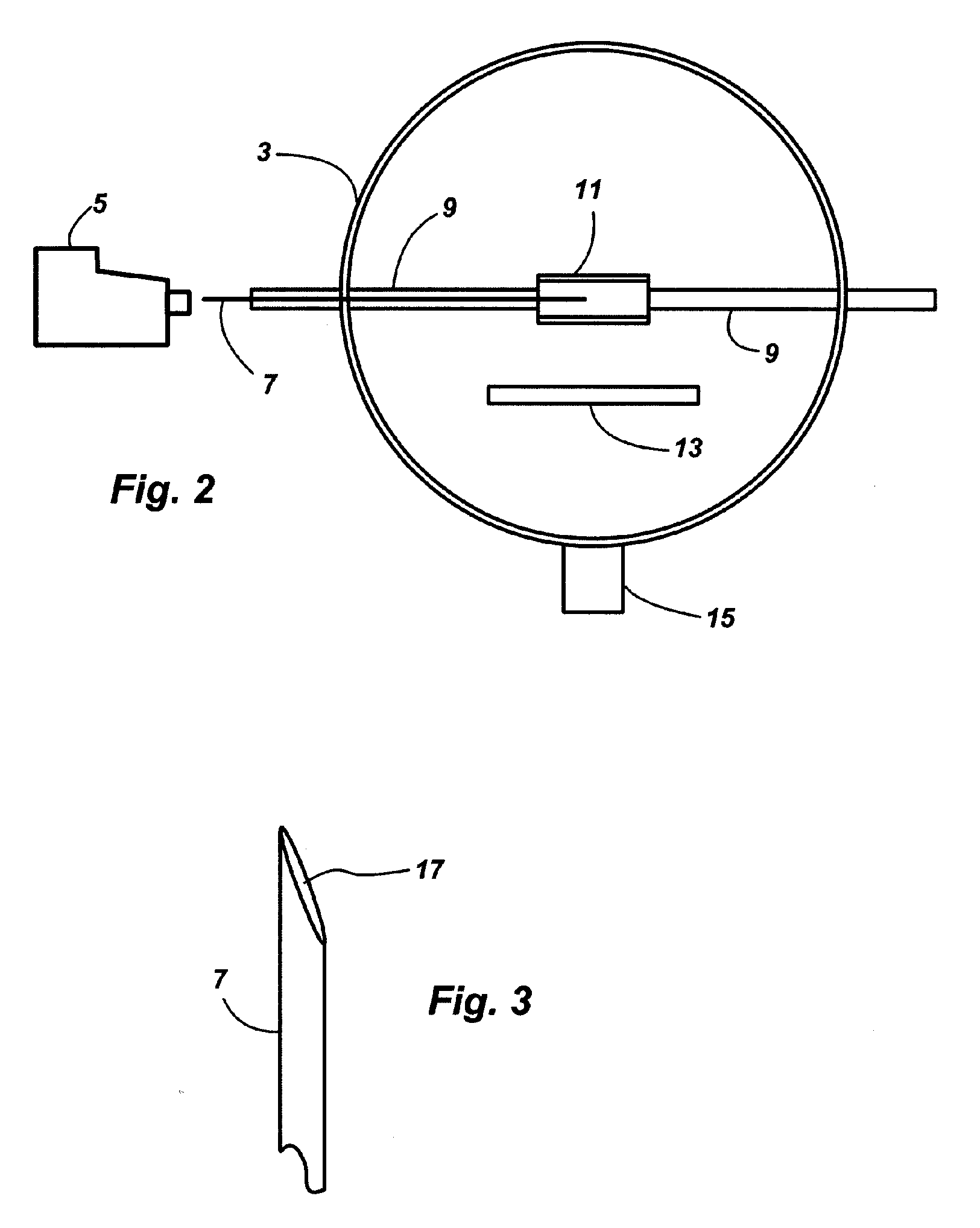

[0017] Both disks (˜25 mm diameter by 0.8 mm thick) and 70 W bulgy-shaped discharge vessels were made by sinter-HIPing. The starting submicron-grained alumina powder had a 150 nm mean particle size and was doped with 220 ppm MgO. For the disks, the measured in-line transmittance was typically quite uniform within the same disk, and from disk to disk. The as-made, sinter-HIPed bodies had very few residual pores. The average grain size was about 0.5 microns. Grain size was determined by multiplying a factor of 1.5 to the intercept size measured using images acquired via scanning electron microscopy (SEM).

[0018] The total transmittance values measured for the sinter-HIPed discharge vessels (polished or non-polished with a 0.8-mm wall thickness) were relatively low, ranging from 69-87% with an average of about 77%. The spectrophotometer in-line transmittance of polished 0.8 mm-thick disks at 600 nm was measured as 50-55%. After annealing at 1025-1150° C. in air for various durations (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittance | aaaaa | aaaaa |

| partial pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com