Cold working die steel

a technology of working die steel and die steel, which is applied in the field of cold working die steel, can solve the problems of hardness degradation, hard to achieve difficulty in achieving a low level of hardness, so as to reduce the toughness or mechanical properties, increase the free cutting property, and reduce the hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

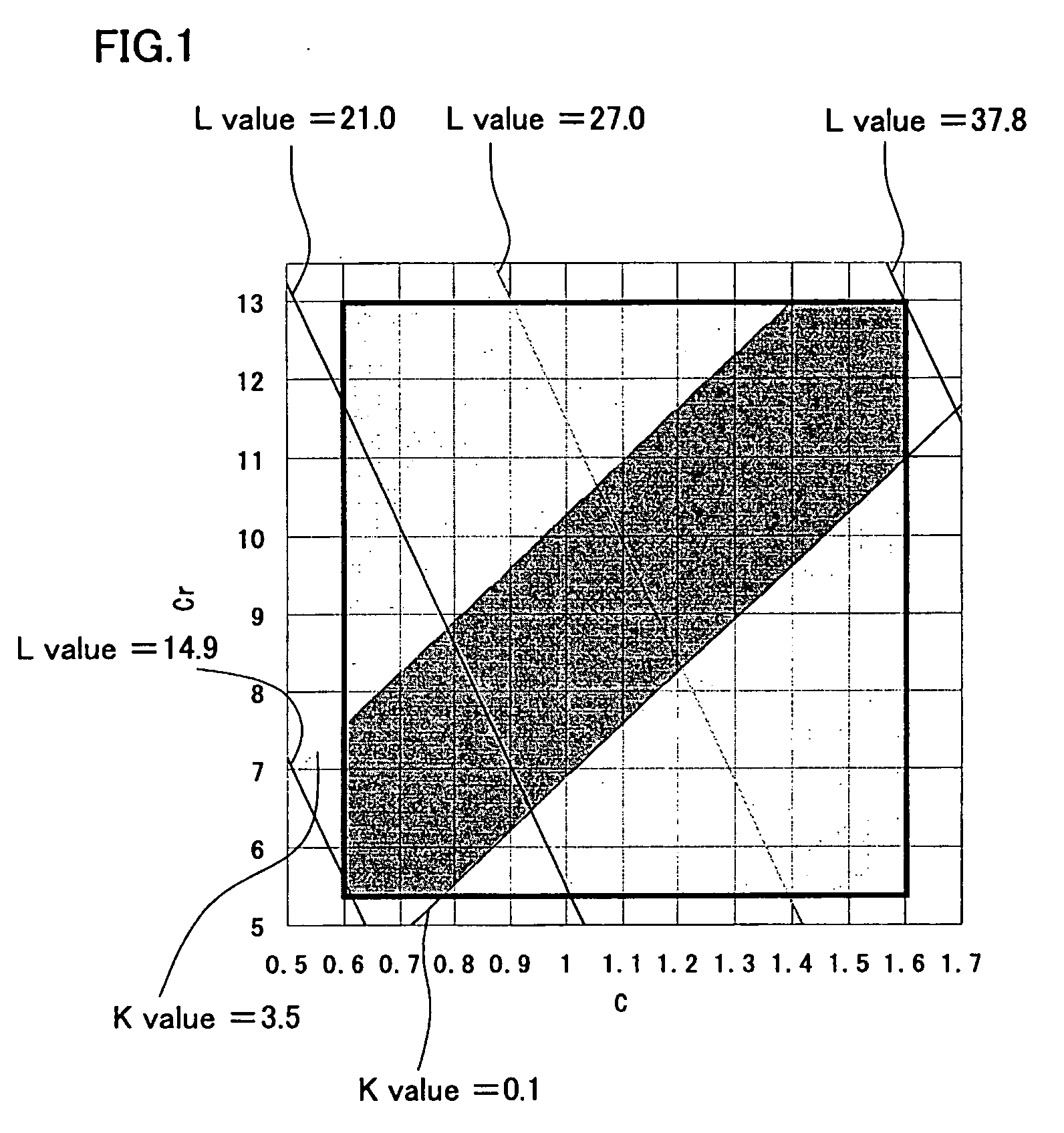

Image

Examples

Embodiment Construction

[0048] First, 200 kg of each of the inventive and comparative steel materials having compositions listed in Table 1 were melted in a vacuum induction furnace, made into an ingot, and the obtained steel ingot was hot-forged so as to produce a 70 mm×70 mm square rod. The rod was then annealed at the temperature listed in Table 2 (cooling rate: 18° C. / h).

[0049] Of the compositions of comparative steels listed in Table 1, those departing from the compositional ranges specified by this invention are indicated by a downward arrow (↓) if they came short of the lower limits, by an upward arrow (↑) if they exceeded the upper limits.

[0050] [Table 1]

TABLE 1Components (wt %)No.CSiMnPSCuNiCrMoW 1Comparative steel0.710.38↑0.930.028↑1.320.117.030.84 2Inventive steel1.230.530.340.060.4310.321.44 3Comparative steel0.710.380.370.0280.0020.09↑1.557.030.84 4Comparative steel0.660.420.320.0130.0010.230.5310.50.32 5Inventive steel0.610.950.470.0040.0630.050.135.72.01 6Inventive steel0.780.750.210.0350....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com