Chemical mechanical polishing slurries and cleaners containing salicylic acid as a corrosion inhibitor

a technology of chemical mechanical polishing and cleaners, which is applied in the preparation of detergent mixtures, chemistry apparatuses and processes, and detergent compositions. it can solve the problems of increasing defects, affecting the yield and performance of wafers, and general disfavored approaches, etc., and achieves the effect of inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Benzotriazole (BTA) is a well-known corrosion inhibitor for copper in various applications in a wide-range of environments. The chemistry of interaction of benzotriazole (BTA) with copper has been studied extensively. See, e.g., G. W. Poling, Corros. Sci., (1970), 10, p.359, and V. Brusic et al., Electrochem. Soc., (1991), 138, p.2253. It is generally accepted that BTA (as well as BTA-ion) chemisorbs on the copper surface and forms an insoluble cuprous surface complex. Under certain conditions the formation of a thick, multilayered coating has been confirmed. See, e.g., V. Brusic et al., Electrochem. Soc., (1991), 138, p.2253.

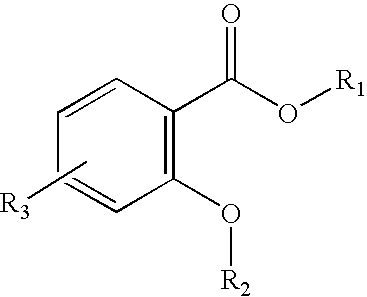

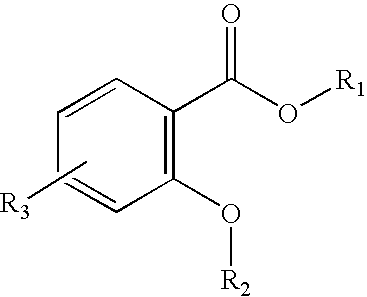

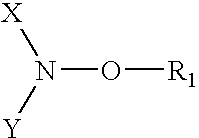

[0044] One aspect of the present invention includes a composition, e.g., used in a method for chemical mechanical polishing of a metal-containing substrate, particularly of copper-containing substrates, containing: between about 0.01% and about 30% by weight of an oxidizing agent based on weight of fluid; between about 0.00001M to about 0.5M, preferably...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com