Continuous plating method of filament bundle and apparatus therefor

a filament bundle and continuous plating technology, applied in the direction of liquid/solution decomposition chemical coating, coating, yarn, etc., can solve the problems of limited adhesion property of electroplating, and low efficiency of plating, so as to achieve uniform application, large output, and continuous and efficient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Where Electroplating of Copper is Applied to Filaments of Polyester

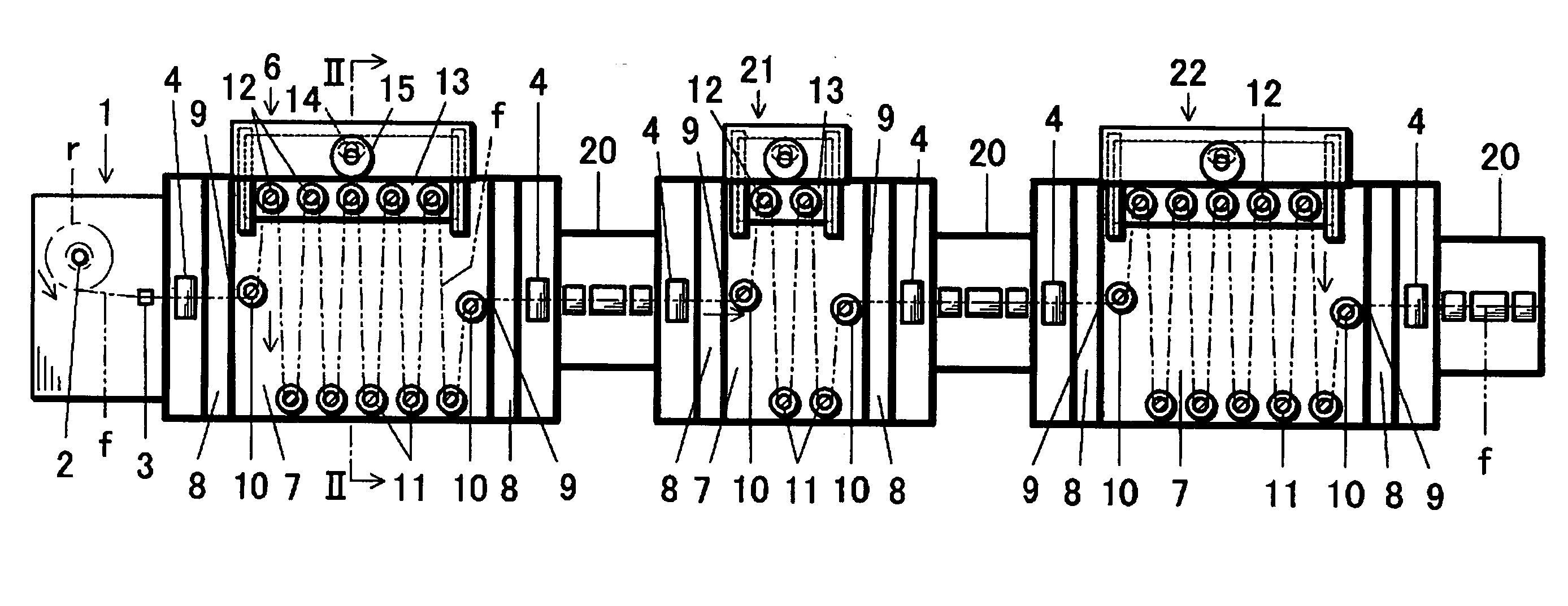

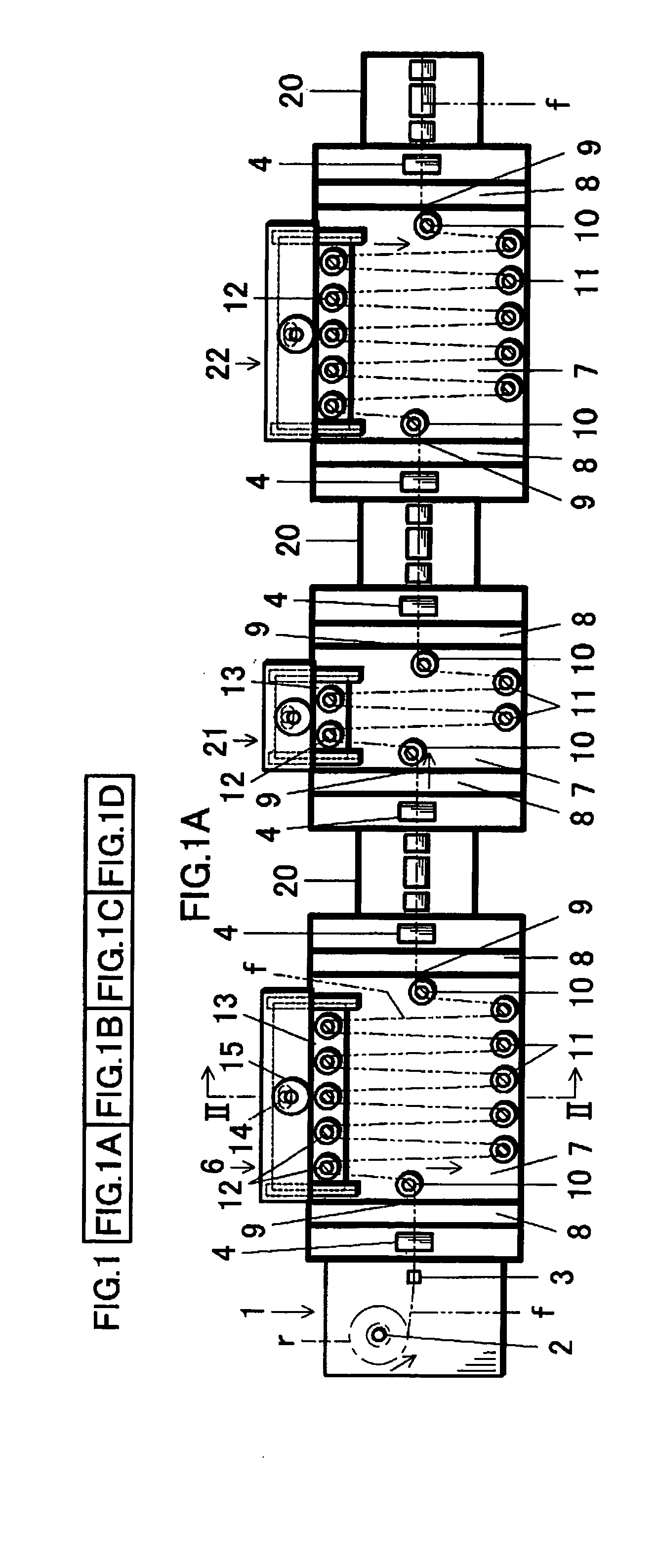

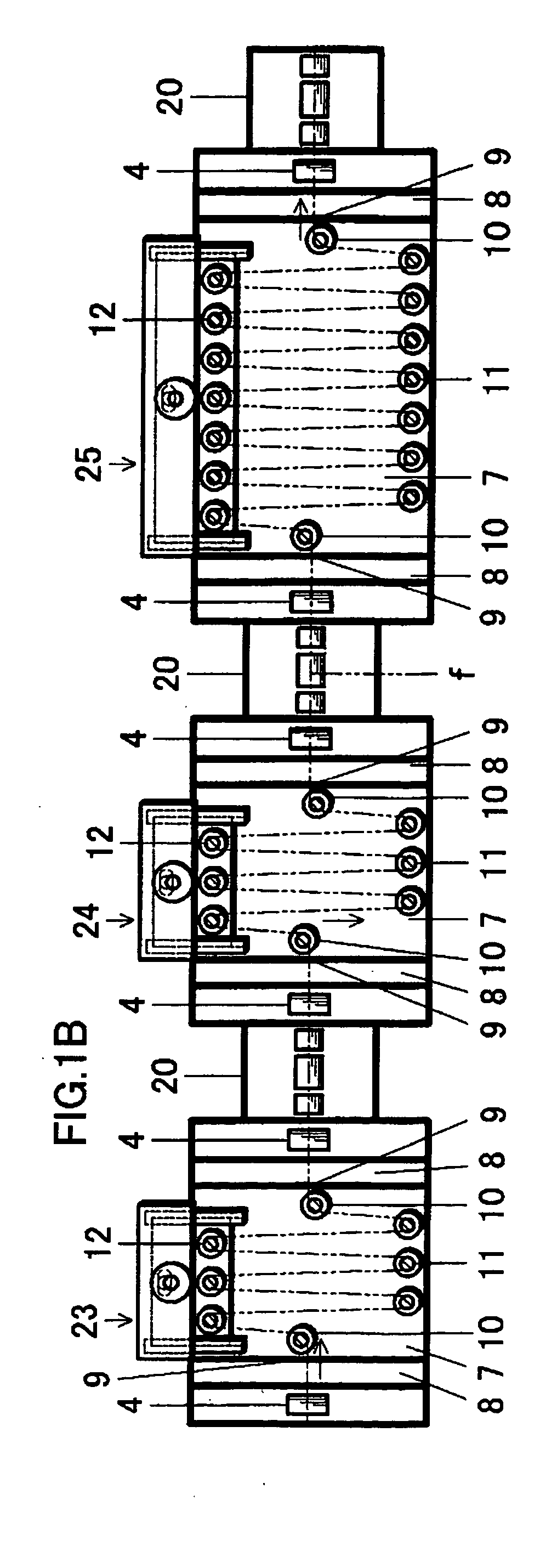

[0083] The filament bundle f is a bundle of polyester filaments of one hundred to several hundreds in number. The traveling speed of the filament bundle f is 50 cm per minute. In the movable guide rollers 12, the reciprocating stroke is 10 cm and the reciprocating frequency is 3 to 4 times per minute. The distance between the movable guide roller 12 and the fixed guide roller 11 is about 50 cm.

[0084] The etching liquid is an aqueous solution in 5% of sodium hydroxide (NaOH), in which the temperature is 45 degrees C. and the immersion time is 5 minutes. The neutralization liquid is an aqueous solution in 5% of hydrochloric acid (HCl), in which the temperature is room temperature and the immersion time is 2 minutes.

[0085] The silane coupling agent for adhering the catalyst, the surface adjustment liquid is an aqueous solution in 0.1% of alfa-aminoethyltriethoxy silane, in which the temperature is 50 degrees C. and t...

example 2

Where Electroplating of Nickel is Applied to Filaments of Aramid

[0089] The filament bundle f is a bundle of aramid filaments of one hundred to several hundreds in number. The traveling speed is 60 cm per minute. In the movable guide rollers 12, the reciprocating stroke is 5 cm and the reciprocating frequency is 6 to 8 times per minute. The distance between the movable guide roller 12 and the fixed guide roller 11 is about 50 cm.

[0090] The etching liquid is an aqueous solution of chromic acid anhydride (CrO3) 30% and sulfuric acid (H2SO4) 15%, in which the temperature is 50 degrees C. and the immersion time is 5 minutes. The neutralization liquid is an aqueous solution in 10% of sodium bisulfate or sodium acid bisulfate (NaHSO3), in which the temperature is room temperature and the immersion time is 2 minutes.

[0091] The silane coupling agent for adhering the catalyst, the surface adjustment liquid, the catalyst liquid and the accelerator liquid are the same as that in the Example ...

example 3

Where Electroplating of Silver is Applied to Filaments of Rayon

[0095] The filament bundle f is a bundle of rayon filaments of one hundred to several hundreds in number. The traveling speed is 70 cm per minute. In the movable guide rollers 12, the reciprocating stroke is 10 cm and the reciprocating frequency is 4 to 5 times per minute. The distance between the movable guide roller 12 and the fixed guide roller 11 is about 50 cm.

[0096] The etching liquid is an aqueous solution in 3% of sodium hydroxide (NaOH), in which the temperature is 45 degrees C. and the immersion time is 5 minutes. The neutralization liquid is an aqueous solution in 3% of hydrochloric acid (HCl), in which the temperature is room temperature and the immersion time is 2 minutes.

[0097] The silane coupling agent for adhering the catalyst, the surface adjustment liquid, the catalyst liquid and the accelerator liquid are the same as that in the Example 1 respectively. The electroless plating liquid is for copper (C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com