Thin germanium oxynitride gate dielectric for germanium-based devices

a technology of germanium-based devices and gate dielectrics, which is applied in the direction of basic electric elements, electrical apparatus, and semiconductor devices, can solve the problems of gate dielectrics, no reliable high-quality gate dielectrics have been found for ge-based materials, and complicated situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

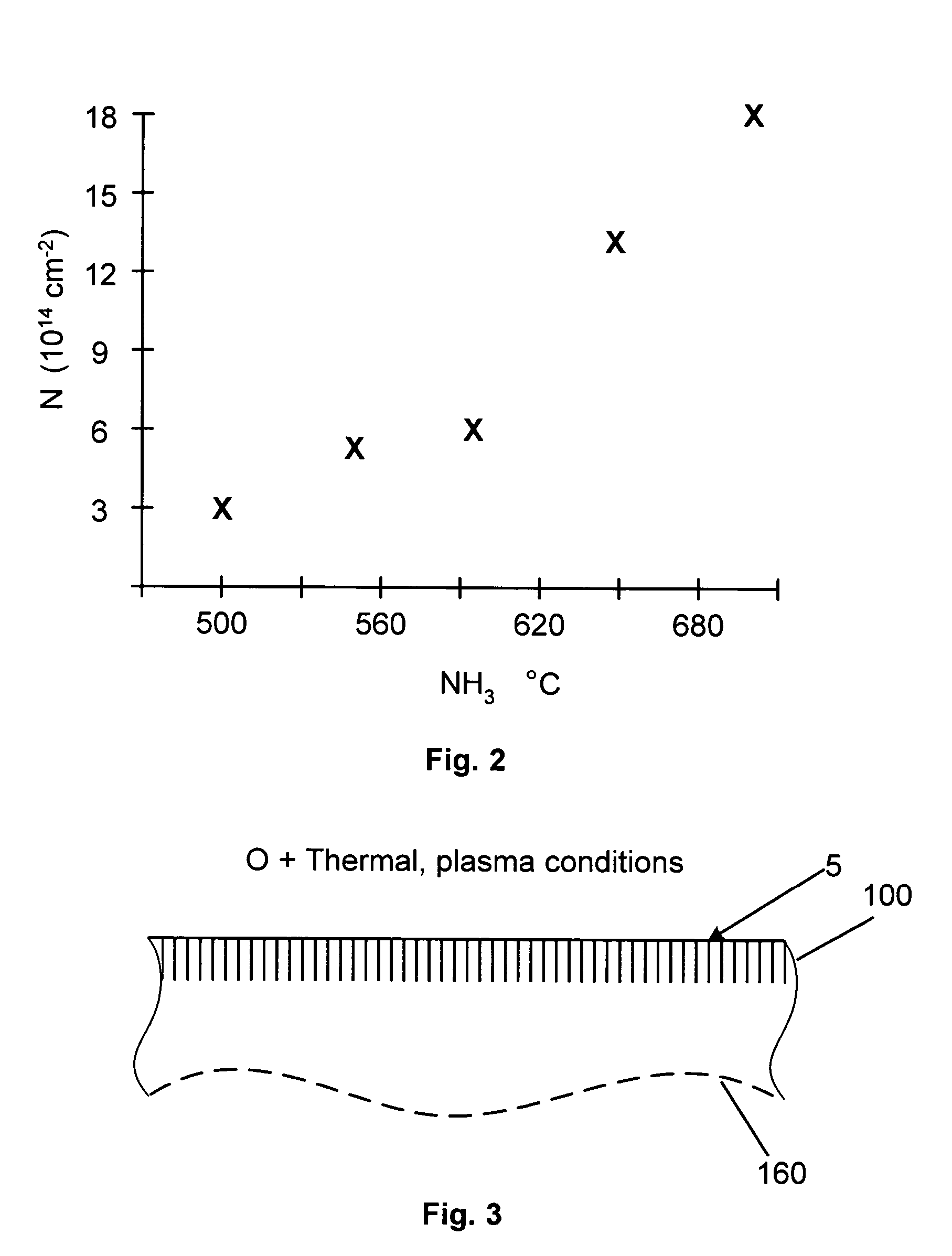

[0018] In the fabrication of high performance Ge-based field effect devices the processing steps that preceded the production of the gate dielectric are known in the art. These steps, such as device isolation, dopant well formation, etc., are assumed to have been completed before commencing the steps of the present invention. However, before the disclosed method steps can take place to produce an the thin germanium oxynitride layer, a surface, referred to as a first surface, of the Ge based material, generally a wafer, the one which will be the recipient of the gate dielectric, has to be properly cleaned. In a representative embodiment such cleaning steps can include, but are not limited to, at least one cycle of oxidation and germanium oxide removal. The oxidation is preferably performed in H2O2 solutions, while oxide removal is accomplished by HF, or HCl, or their mixtures. After the cleaning step the first surface of the Ge based material, which is host to the devices, is ready f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com