Methods and apparatus for processing temperature sensitive materials

a technology for temperature sensitive materials and processing equipment, applied in the direction of centrifugal force sediment separation, energy-based chemical/physical/physical-chemical processes, peptides, etc., can solve the problems of inability to obtain enough material to meet these demands, inability to use known material concentration methods, and inability to meet the requirements of storage and shipment of blood products. the effect of less than fully successful known material concentration methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

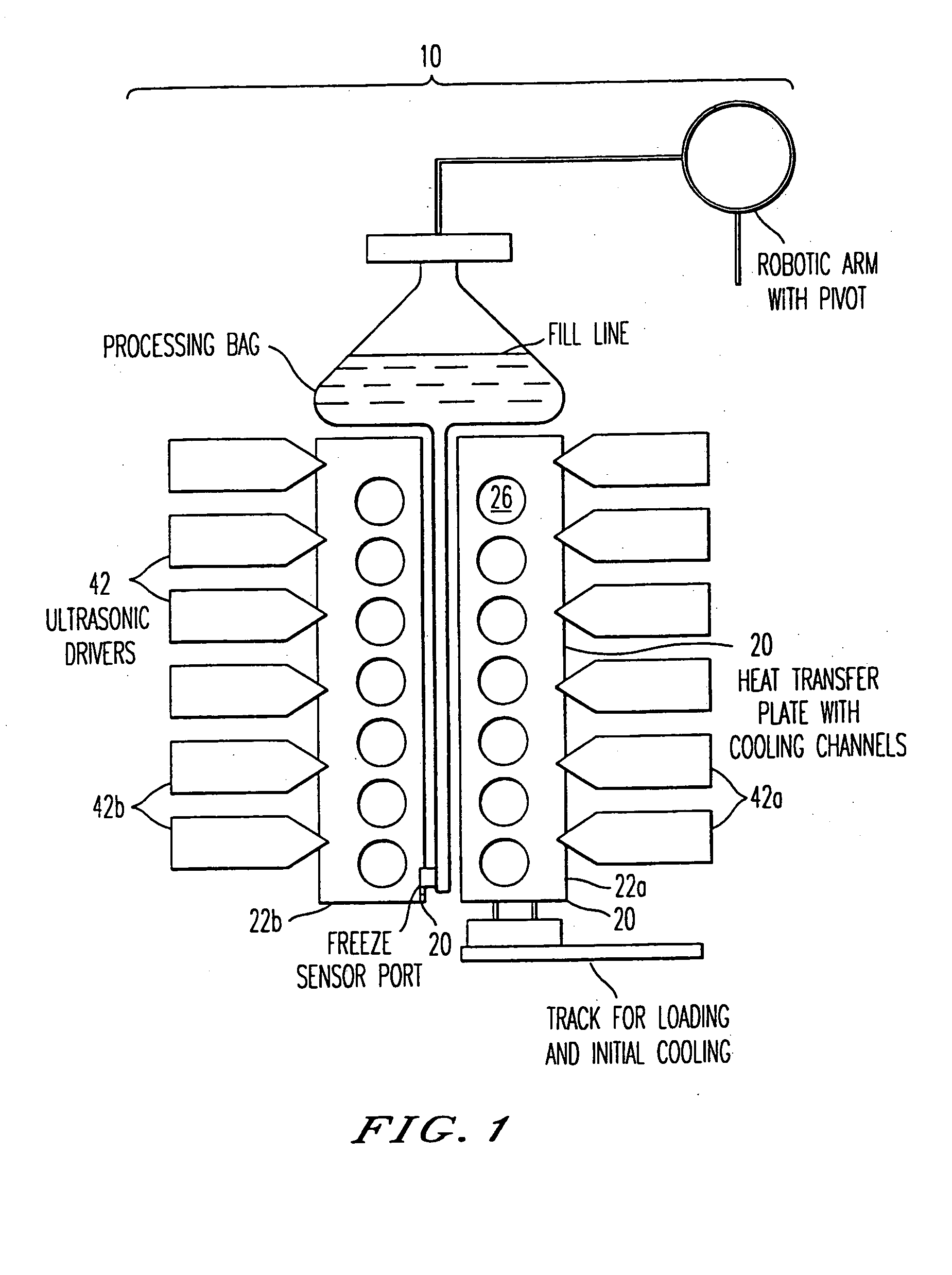

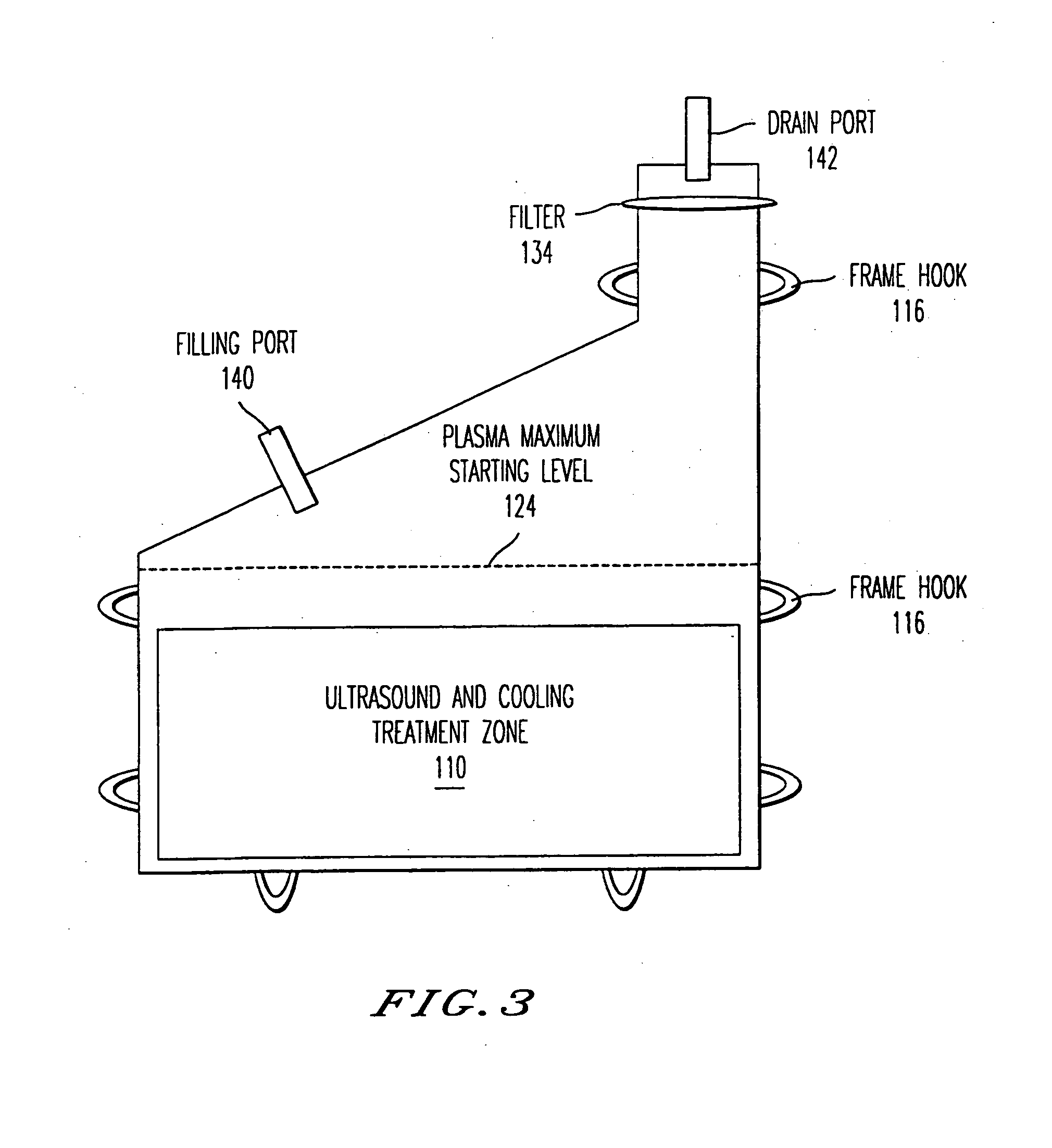

[0227] By way of illustration, and without limitation to the specific embodiments described, the present invention will be further illustrated by way of the following example. Approximately 200 mL of human plasma is introduced into the treatment chamber 110 of a concentration container 100, substantially as described above, through the material inlet fitting 140. The concentration container 100 is filled to an initial level 124, just below the collection port 122. The concentration container 100 or a supporting frame (not shown) is gripped at anchor points 116 by a robot arm having vacuum assisted grippers for engaging the concentration container 100, and is transferred to a position between two cooling plates 22a and 22b. The cooling plates 22a, 22b are closed by movable frame arms, to engage the movable chamber walls 112, 114 of the treatment chamber 110. Vacuum assisted grippers on the cooling plates 22a, 22b hold the walls 112, 114 in place. The cooling plates 22a, 22b are movab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com