Composite ceramic Raoult nozzle for cold spray coating

A composite ceramic, cold spray technology, applied in the direction of spray device, spray device, etc., can solve the problems of expensive, bonding, etc., and achieve the effects of high speed, high airflow speed, and high drag efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

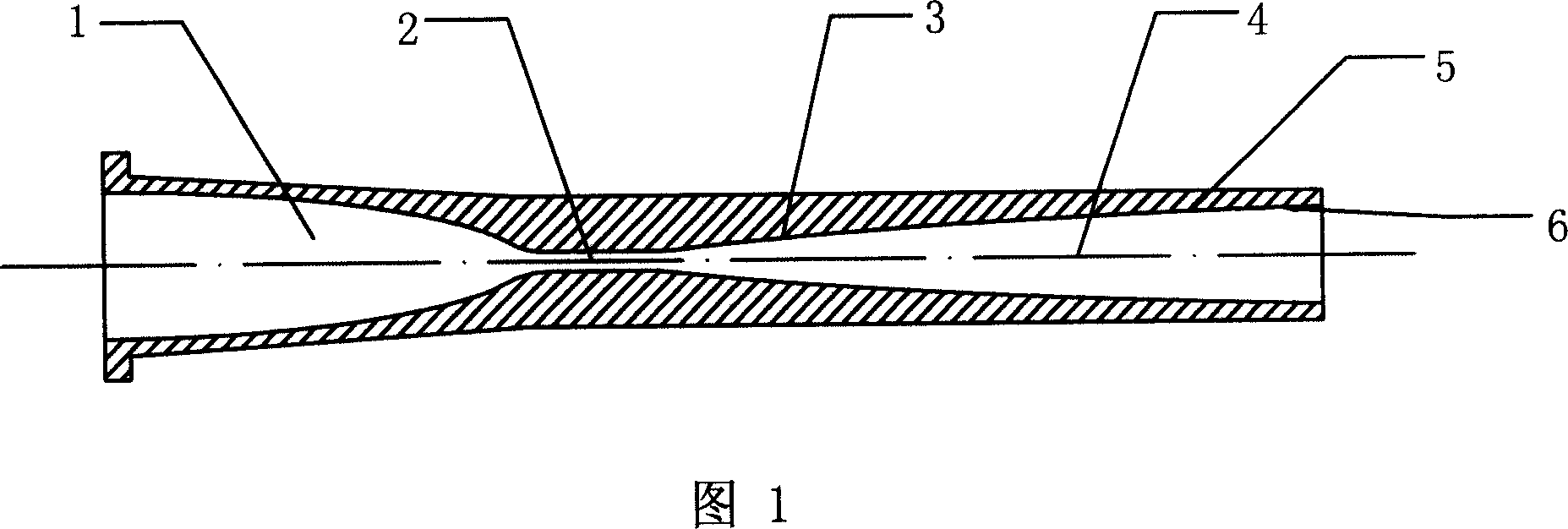

[0042] The outer wall 7 of the Laval type cold spray nozzle is a fully stabilized zirconia ceramic with 3.5 mol% yttria, and the boron nitride ceramic is the cold spray nozzle for the throat and the inner wall 8 of the diffusion section. The length of the diffuser section 4 is 10 mm, the length of the equal-diameter section of the throat is 6 mm, a / b is 5, and the ratio of the diameter of the throat 2 to the diameter of the nozzle outlet is 1:2.5. Spraying aluminum-zinc alloy powder, the particle size range is 100-300μm. The spraying process parameters are: nitrogen pressure 2.5MPa, temperature 400°C. The experimental results are: the average velocity of the particles is 600m / s, no throat sticking occurs, no oxidation occurs to the particles, and the deposition efficiency is 85%.

[0043] It is worth pointing out that the conventional cold spraying technology prepares aluminum-zinc alloy powder coating, the highest particle size is less than 100μm, the gas pressure is above 3...

Embodiment 2

[0045] The outer wall 7 of the Laval type cold spray nozzle is alumina ceramics, and the boron nitride ceramic is the cold spray nozzle of the throat and the inner wall 8 of the diffusion section. The length of the diffuser section 4 is 15 mm, the length of the equal-diameter section of the throat is 7 mm, a / b is 6, and the ratio of the diameter of the throat 2 to the diameter of the nozzle outlet is 1:3. Spray titanium powder, the particle size range is 200-300μm. The spraying process parameters are: nitrogen pressure 3.0MPa, temperature 400°C. The experimental results are: the average velocity of the particles is 800m / s, no throat sticking occurs, the particles do not oxidize, and the deposition efficiency is 80%.

[0046] It is worth pointing out that when conventional cold spray nozzles prepare titanium powder coatings, the largest particle size is less than 100 μm, the gas pressure is above 3.5 MPa, and the deposition efficiency is about 80%. Because the nozzle manufact...

Embodiment 3

[0048] The outer wall 7 of the Laval type cold spray nozzle is 5mol% yttrium oxide fully stabilized zirconia ceramics, and the boron nitride ceramic is the cold spray nozzle of the throat and the inner wall 8 of the diffusion section. The length of the diffuser section 4 is 10 mm, the length of the equal-diameter section of the throat is 8 mm, a / b is 6, and the ratio of the diameter of the throat 2 to the diameter of the nozzle outlet is 1:2.8. Spray copper powder, the particle size range is 10-100μm. The spraying process parameters are: nitrogen pressure 3.5MPa, temperature 800°C. The experimental results are: the average velocity of the particles is 1200m / s, no throat sticking occurs, the particles do not oxidize, and the deposition efficiency is 92%.

[0049] Compared with conventional cold spray nozzles, conventional cold spray nozzles require the average velocity of particles to reach 1200m / s, and the nitrogen pressure used must be above 4.0MPa. To reduce the pressure, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com