Inert medium spray-atomizing-drying machine by vibration

An inert medium, atomization drying technology, used in drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of high capital construction and equipment investment, small heat transfer and mass transfer coefficients, and the inability of users to purchase, etc. Achieve the effect of improving drying efficiency, reducing investment and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

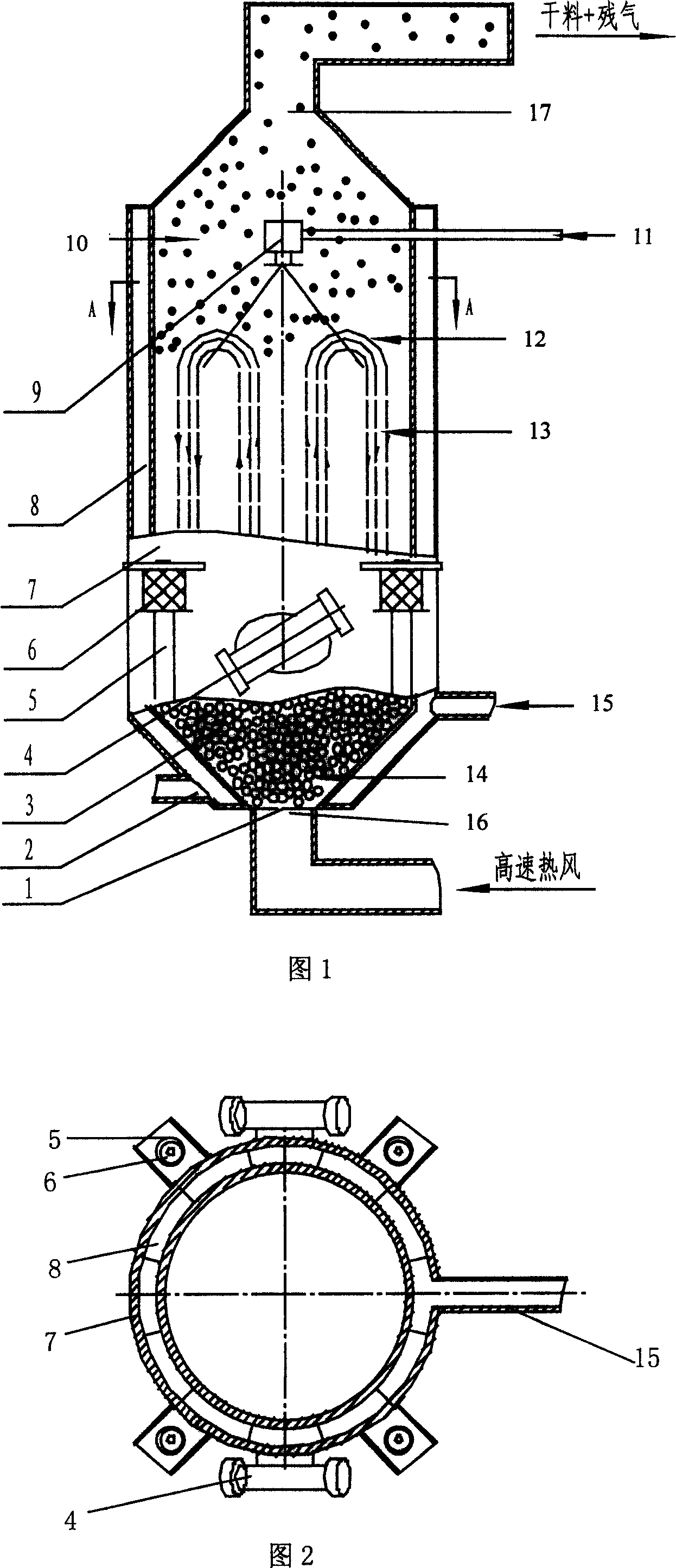

[0023] Embodiment 1: As shown in Figure 1, the structure of the present invention: its tower body is a cylindrical shell, and a feed liquid pipe and a pressure nozzle 9 for atomization are installed on the upper part of the drying tower shell 7, and the drying tower shell 7 is up and down. The two ends are conical cylinder structures, and there are hot air outlets 16 on the lower part of the drying tower cylinder body 7, and a discharge outlet 17 on the upper part, and two vibrating devices with opposite inclination directions are installed at the relative positions on both sides of the lower part of the drying tower cylinder body 7. Motor 4; a partition 1 is placed at the port of the lower cone, and an inert medium 3 is placed on the partition 1 of the lower cone.

[0024] In this example, a support 5 is fixed around the drying tower body 7, and the four corners of the support 5 are made of four round steel pipes, which are formed by steel welding. The support 5 steel pipes ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com