Ecological briquette surface curing agent and its preparing method

A surface-cured, ecological technology, applied in chemical instruments and methods, other chemical processes, transportation objects, etc., can solve problems such as traffic safety threats, deterioration of the working environment of flight attendants, deterioration of the environment of employees and passengers, and achieve huge economic and social benefits. benefit, reduce flying losses along the way, and reduce the effect of human and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Raw material ratio:

[0026] Raw material name Proportion (weight %) Raw material name Proportion (weight %)

[0027] Polyvinyl alcohol 1 Sodium hypochlorite 0.6

[0028] Corn starch 5 Sodium thiosulfate 0.08

[0029] Copper sulfate 0.01 Borax 0.05

[0030] Caustic soda 0.6 Water 92.5

[0031] Preparation:

[0032] The first step, graft modification

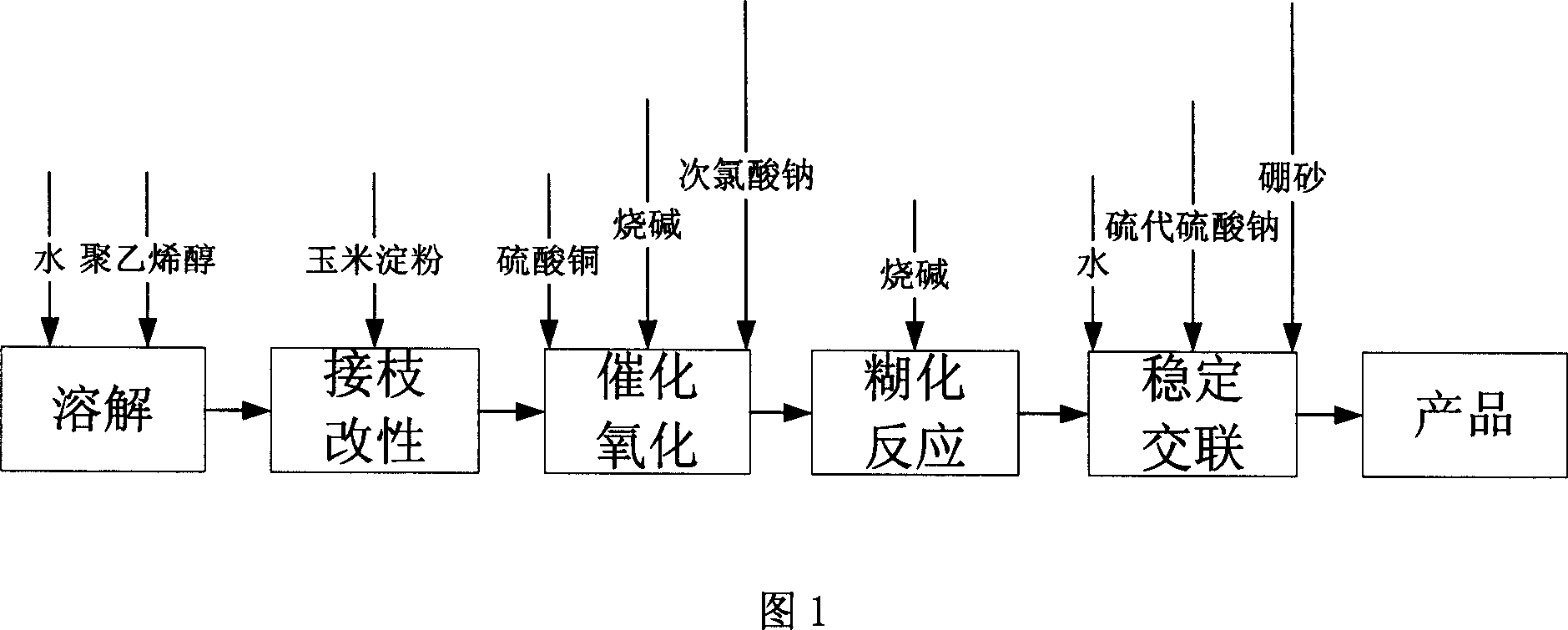

[0033] According to the process flow chart in Figure 1, add 55% of the total water in the raw material ratio to the reactor, then add 1% polyvinyl alcohol, stir, heat up to 95°C to completely dissolve the polyvinyl alcohol, then cool down to 60°C, Add 5% cornstarch, stir and keep warm for 1h to carry out graft modification;

[0034] The second step, catalytic oxidation

[0035] After modification, cool the material to 25°C, add 0.01% copper sulfate to the reaction kettle, then add one-sixth of the total caustic soda, stir evenly, then add 10% sodium hypochlorite (0.4-0.8%) solution, catalytic oxidation Reaction 1h....

Embodiment 2

[0041] Raw material ratio:

[0042] Raw material name Proportion (weight %) Raw material name Proportion (weight %)

[0043] Polyvinyl alcohol 1.5 Sodium hypochlorite 0.8

[0044] Corn starch 6 Sodium thiosulfate 0.1

[0045] Copper sulfate 0.01 Borax 0.06

[0046] Caustic soda 0.6 Water 94.5

[0047] Preparation:

[0048] According to the ratio of raw materials in Example 2, the specific preparation steps are the same as in Example 1, but the heating temperature of graft modification is 99°C, and then the temperature is lowered to 50°C.

Embodiment 3

[0050] Raw material ratio:

[0051] Raw material name Proportion (weight %) Raw material name Proportion (weight %)

[0052] Polyvinyl alcohol 0.5 Sodium hypochlorite 0.4

[0053] Corn starch 4 Sodium thiosulfate 0.06

[0054] Copper sulfate 0.005 Borax 0.03

[0055] Caustic soda 0.4 Water 90.5

[0056] Preparation:

[0057] According to the ratio of raw materials in Example 3, the specific preparation steps are the same as in Example 1, but the heating temperature of graft modification is 97°C, and then the temperature is lowered to 55°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com