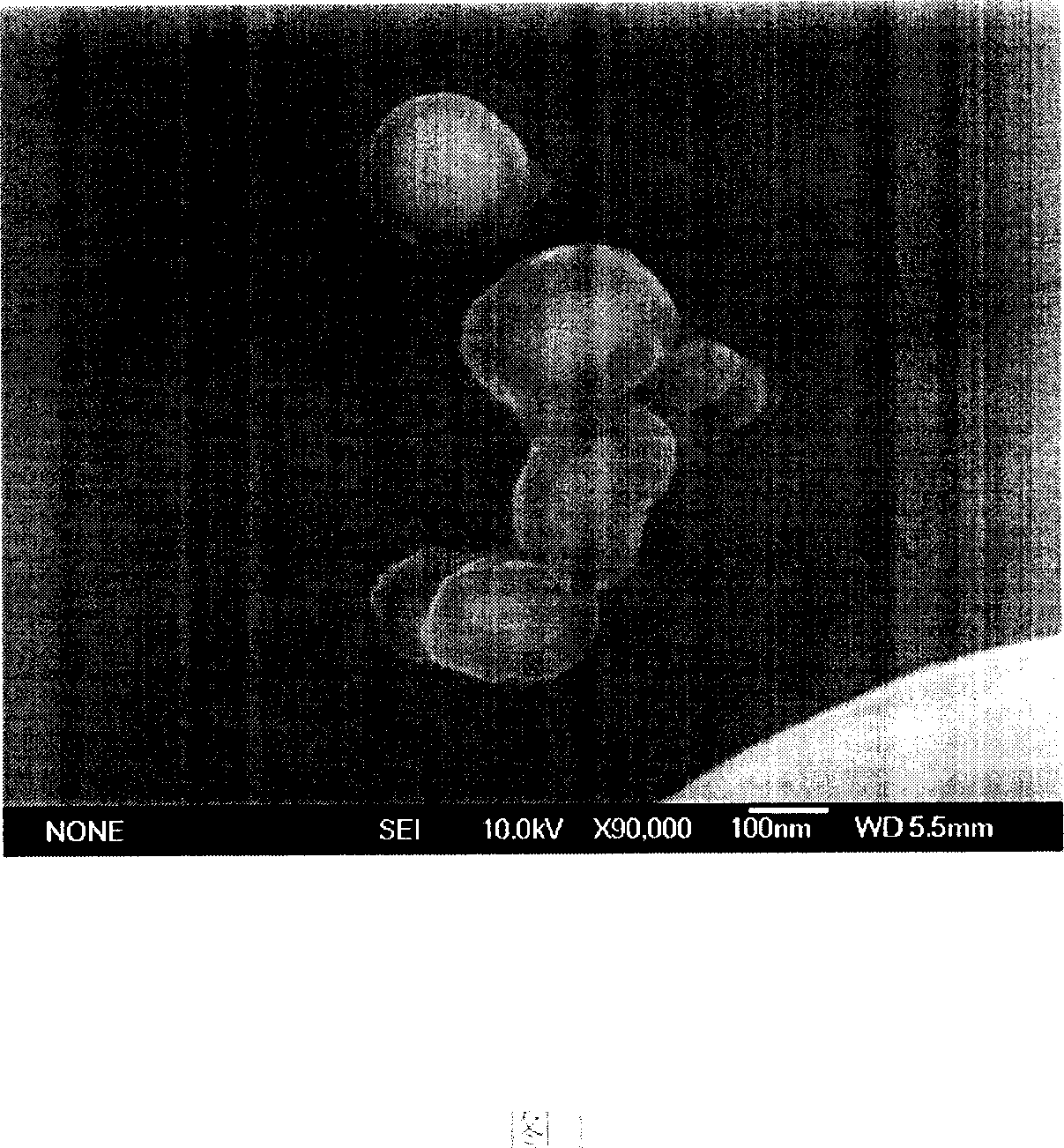

Prepn process of composite onion-shaped fullere material with homogeneous grain size

A technology of onion-like fullerene and composite materials, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of uneven particle size and low purity of onion-like fullerene, and achieve convenient use of templates and high purity. High, foreground attractive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 2g of ferrocene catalyst and zeolite powder with a pore size of 100nm respectively, put them into quartz boats respectively, put the quartz boat loaded with zeolite into the middle of the quartz tube reactor, and place the quartz boat loaded with ferrocene catalyst in the middle of the quartz tube reactor. At one end of the gas inlet of the quartz tube, the quartz tube reactor is closed, and argon gas is introduced to exhaust the air in the quartz tube reactor. After the temperature of the reaction zone rises to 1273K, the valve of the acetylene gas is opened to allow the argon and acetylene gas to Mix in a ratio of 10:1, flow through the quartz tube reactor continuously, heat the ferrocene catalyst in the quartz boat, and the ferrocene catalyst will be sublimated and decomposed by heat to form nano-sized particles as catalysts, which are blown into the reaction zone by argon flow for reaction , the carbon source is provided by pyrolyzed acetylene gas and ferrocene...

Embodiment 2

[0021] Weigh 2g each of the cobaltocene catalyst and zeolite powder with a pore size of 100nm, and put them into quartz boats respectively. At one end of the gas inlet, the quartz tube reactor is closed, and argon is introduced to empty the air in the quartz tube reactor. After the temperature in the reaction zone rises to 1173K, the valve of methane gas is opened to make the ratio of argon gas and methane gas to 10: The ratio of 1 is mixed, continuously flows through the quartz tube reactor, and the cobaltocene catalyst in the quartz boat is heated. The cobaltocene catalyst is sublimated and decomposed by heat to form nano-sized particles, which are blown into the reaction zone by the argon flow for reaction. The carbon source is heated by heat. The decomposed methane gas and cobaltocene catalyst are provided together, and these substances are recombined to form cobalt-encapsulated onion-like fullerene. After the catalyst is consumed, it is kept for 30 minutes. After the quart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com