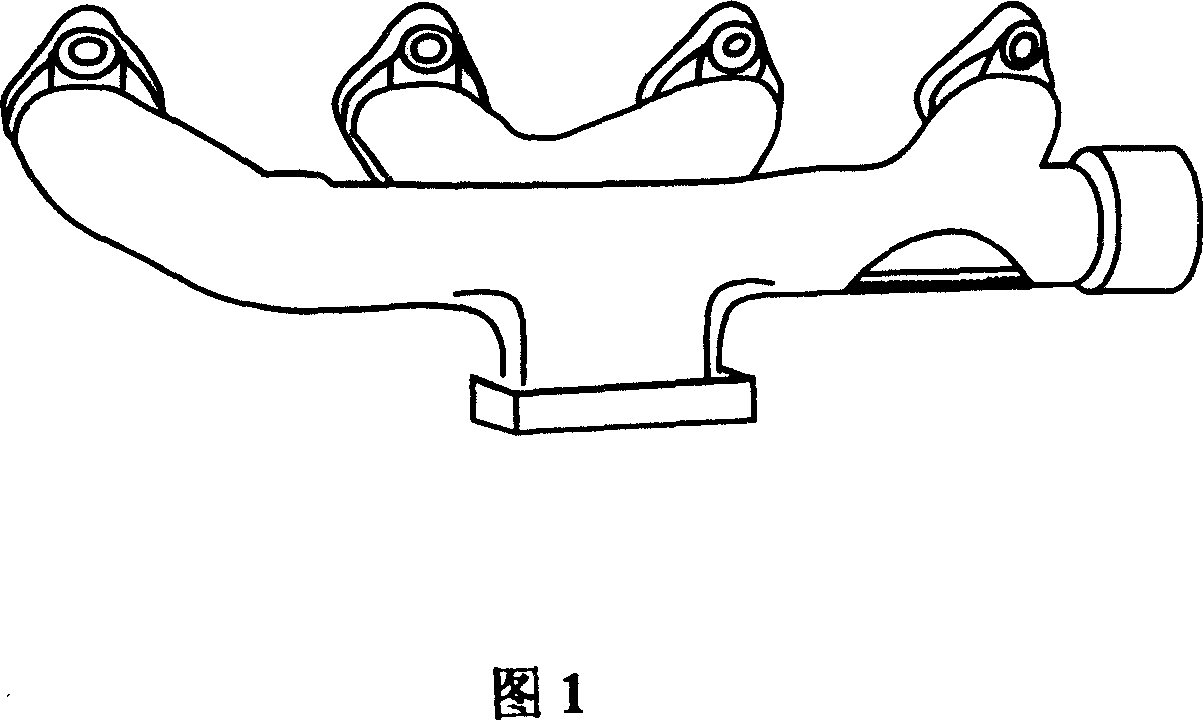

High nickel austenite spheroidal graphite cast iron automobile exhaust branch pipe and casting method

A technology of exhaust manifold and ductile iron, which is used in exhaust devices, mechanical equipment, engine components, etc., can solve the problems of large surface tension, large shrinkage tendency, and many hot joints, so as to ensure the filling and pouring speed. , the effect of reducing temperature gradient and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

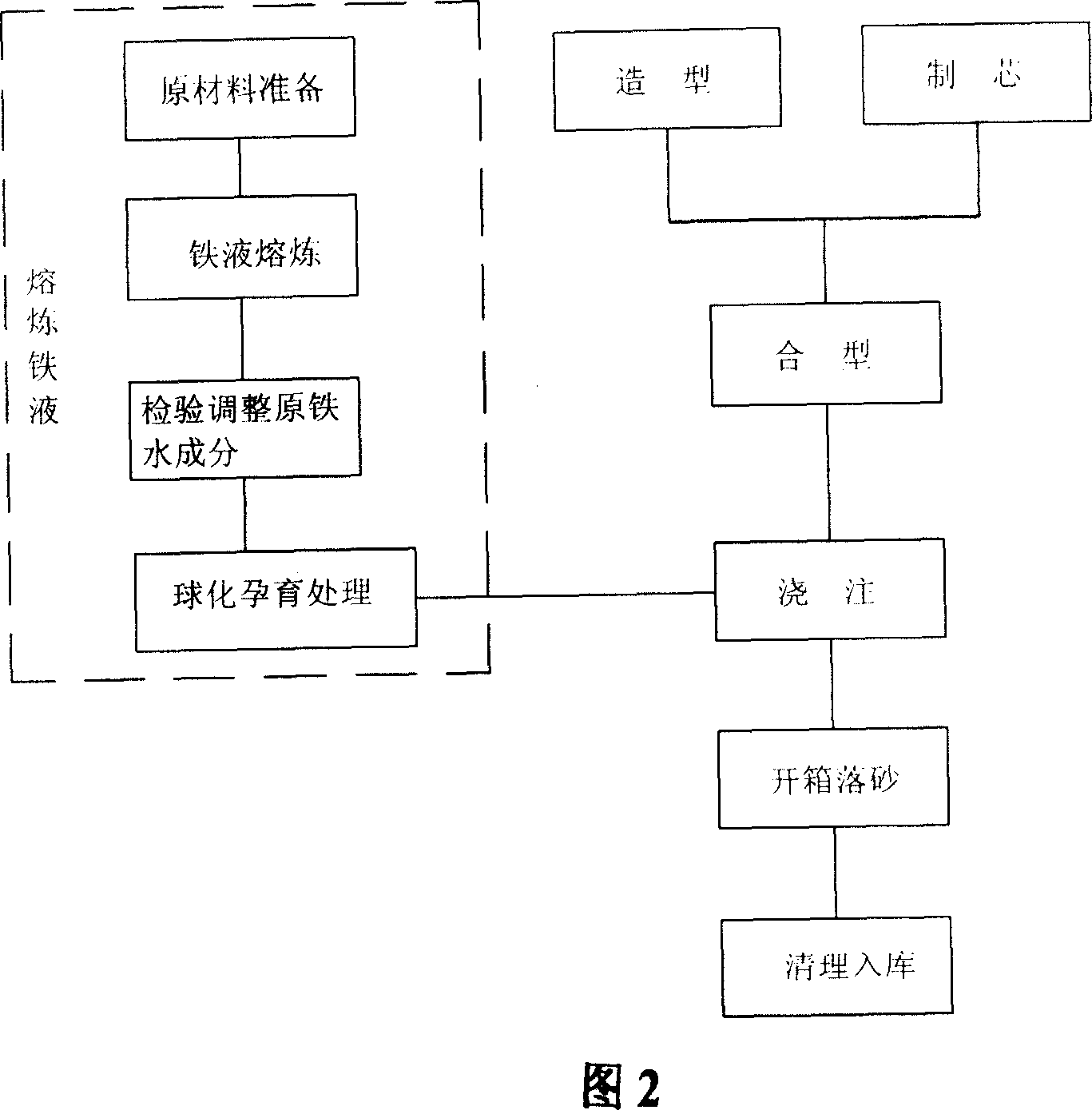

[0018] As shown in Figure 2, the casting method of the high-nickel austenitic ductile iron automobile exhaust manifold adopts the processes of core making, molding, forming, smelting molten iron, pouring, unpacking and shedding sand, and cleaning and warehousing. The main improvement process steps are:

[0019] 1. Core making: low nitrogen and high temperature coated sand is used, the strength of the coated sand is 3.4Mpa, and the low gas emission is 14m / g; the inner sand core of the exhaust manifold is an internal flow sand core, and the exhaust performance under working conditions Well, the outer cavity sand core is inlaid with cold iron or inner cold iron at the position of the two tube clamps to reduce the temperature gradient and balance the temperature field; the core making and molding processes can be carried out at the same time.

[0020] 2. Modeling: After the film-coated sand core is combined and formed, the large-hole flow pouring system technology is adopted, and ...

Embodiment 2

[0026] As shown in Figure 2, the casting method adopts the processes of core making, molding, forming, melting molten iron, pouring, unpacking and shaking out and cleaning and storing. The main improvement process steps are:

[0027] 1. Core making: low nitrogen and high temperature coated sand is used, the strength of the coated sand is 4Mpa, and the low gas emission is 12m / g; the inner sand core of the exhaust manifold is an internal flow sand core, and the exhaust performance is good under working conditions , the outer cavity sand core is inlaid with cold iron or inner cold iron at the position of the two tube clamps to reduce the temperature gradient and balance the temperature field; the molding process can be carried out at the same time as the core making.

[0028] 2. Modeling: After the film-coated sand core is combined and formed, the large-hole flow pouring system technology is adopted, and the side riser is adopted, and the static pressure head during pouring is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com