Dipped barium wolfram cathode and process for its manufacture

A technology of barium tungsten cathode and cathode body, which is applied in the field of impregnated barium tungsten cathode and the preparation of the impregnated barium tungsten cathode, which can solve the problems of complicated process, insufficient life, and insufficient emission current of impregnated barium tungsten cathode, and achieve process repeatability And good stability, shorten the production cycle, facilitate the effect of electron emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

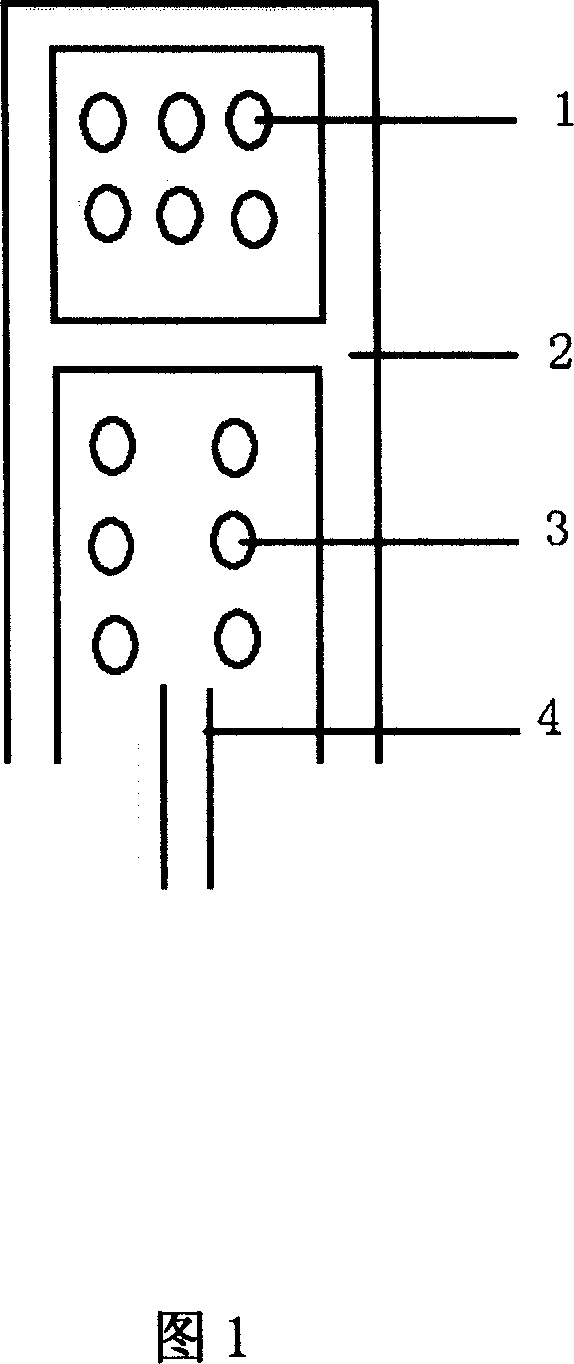

[0031] The cathode body prepared by the present invention has a diameter of 3.6mm and a thickness of 2mm.

[0032] Process 1:

[0033] 1) Put tungsten powder and chromium oxide into a 500°C hydrogen furnace for annealing to thoroughly purify and enhance their plasticity.

[0034] 2) Weigh 1 gram of chromium oxide and 19 grams of tungsten powder (both converted to 100%, the purity of chromium oxide is 95%, and the purity of tungsten powder is 95.2%), grind the two materials to 300 mesh, and mix well , take 200 mg of the mixture, and press it into a cathode body with a molybdenum cylinder inside.

[0035] 3) Put the cathode body prepared in step 2 into a hydrogen furnace, and keep it warm for 5 hours when the temperature reaches 1700°C.

[0036] 4) Place the cathode body prepared in step 3 in aluminate powder, immerse in a hydrogen atmosphere at 1600° C. for 3 minutes, and remove the floating salt after immersion with tungsten wool.

[0037] 5) Install the heater.

[0038] D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com