Impregnated barium-tungsten cathode solder and method for using same

A technology of barium tungsten cathode and brazing filler metal, which is applied in the direction of welding/cutting medium/material, welding medium, manufacturing tools, etc. It can solve the problems of Mo tube cracking, low cathode yield, and shedding, etc., and achieve long service life and stability Good performance and low vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

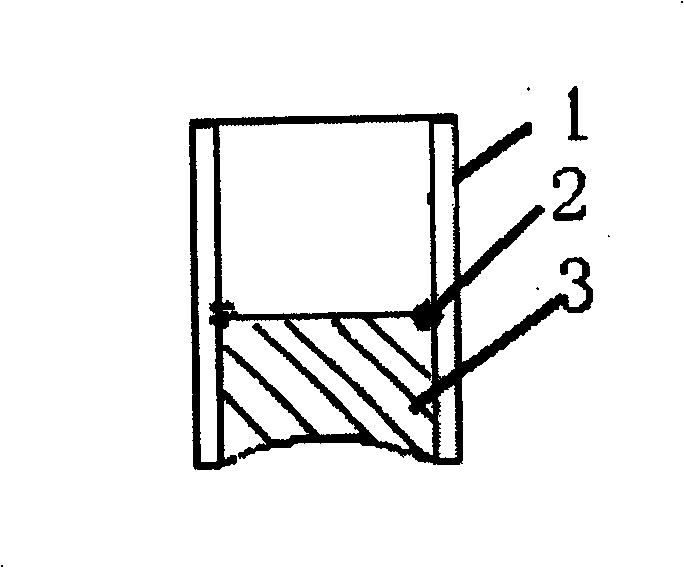

Image

Examples

Embodiment Construction

[0023] The cathode body prepared by the present invention has a diameter of 3.6mm and a thickness of 2mm.

[0024] Process 1:

[0025] 1) Put the palladium powder, tungsten powder and cobalt powder into a 500°C hydrogen furnace for annealing to thoroughly purify and enhance their plasticity.

[0026] 2) Take by weighing 1 gram of palladium powder, 10 gram of tungsten powder, 40 gram of cobalt powder, (all converted into 100%, the purity of palladium powder is 95.4%, the purity of tungsten powder is 95.2%, the purity of cobalt powder is 95.5% ), the three materials are ground to 300 mesh, mixed and pressed;

[0027] 3) Spread the solder on the junction of the non-emitting surface W-base and the molybdenum cylinder, with a thickness of 2-3 mm. Put the coated cathode into the hydrogen furnace, raise the temperature to 1600°C and keep it for 120 seconds, and then lower it to 1000°C. Keep warm for 3 minutes and cool to room temperature;

[0028] 4) Place the cathode body prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com