Impregnated barium-tungsten cathode solder and method for using same

A barium tungsten cathode and solder technology, applied in welding/cutting media/materials, welding media, manufacturing tools, etc., can solve the problems of Mo tube cracking, falling off, low cathode yield, etc., and achieve long service life, steam Small pressure, strong welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

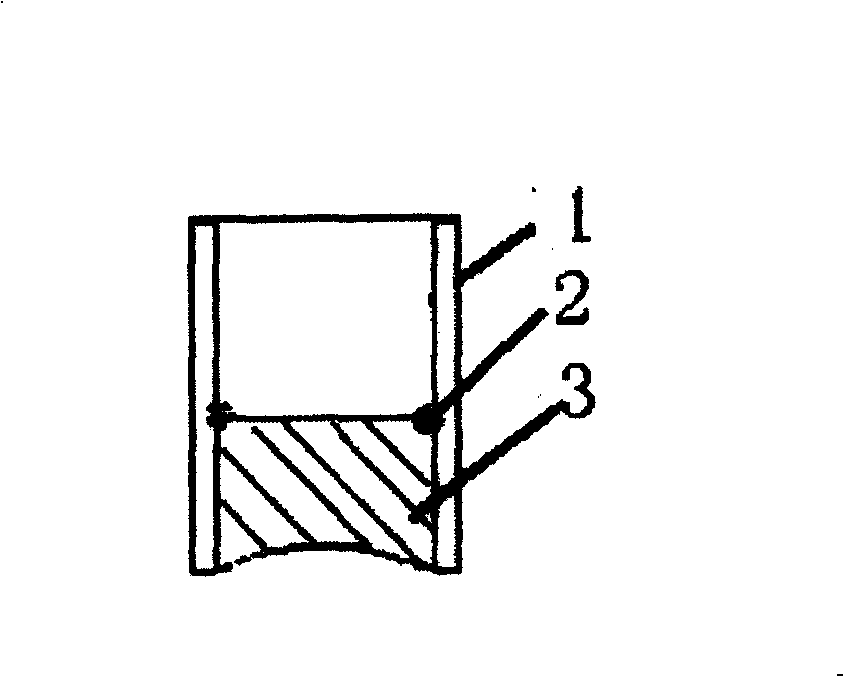

Image

Examples

Embodiment Construction

[0023] The cathode body prepared by the present invention has a diameter of 3.6mm and a thickness of 2mm.

[0024] Process 1:

[0025] 1) Put the palladium powder, molybdenum powder and cobalt powder into a 500°C hydrogen furnace for annealing to thoroughly purify and enhance their plasticity.

[0026] 2) Take by weighing 1 gram of palladium powder, 10 gram of molybdenum powder, 40 gram of cobalt powder, (all converted into 100%, the purity of palladium powder is 95.4%, the purity of molybdenum powder is 95%, the purity of cobalt powder is 95.5% ), the three materials are ground to 300 mesh, mixed and pressed;

[0027] 3) Spread the solder on the junction of the non-emitting surface W-base and the molybdenum cylinder, with a thickness of 2-3 mm. Put the coated cathode into the hydrogen furnace, raise the temperature to 1600°C and keep it for 120 seconds, and then lower it to 1000°C. Keep warm for 3 minutes and cool to room temperature;

[0028] 4) Place the cathode body pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com