Photosensitive resin composition for photosensitive clearance material

A technology of photosensitive resin and composition, which is applied in the direction of photosensitive materials, optics, and optomechanical equipment used in optomechanical equipment, and can solve problems such as insufficient plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2 and comparative example 1

[0161] The structure, molar ratio, etc. of the binder resin Aa used in Example 1 are shown in formula (X) and Table 1. In Table 1, a to d represent molar ratios.

[0162]

[0163] Description of constituent units

[0164] a: Structural unit introduced from (A2) in copolymer 1.

[0165] b: Structural unit introduced from (A2) in copolymer 1.

[0166] c: A structural unit introduced by reacting (A3) to the structural unit introduced from (A4) in the copolymer 1.

[0167] d: A structural unit introduced by reacting (A5) at a site derived from (A3) in copolymer 2.

[0168] Resin Aa

a

0.25

b

0.25

c

0.15

d

0.35

R1

H

mw

18000

Mw / Mn

2.2

[0169] The polystyrene conversion weight average molecular weight (Mw) and the number average molecular weight (Mn) of the said binder polymer were measured by the GPC method under the following conditions.

[0170] Device: H...

Embodiment 3、 comparative example 2

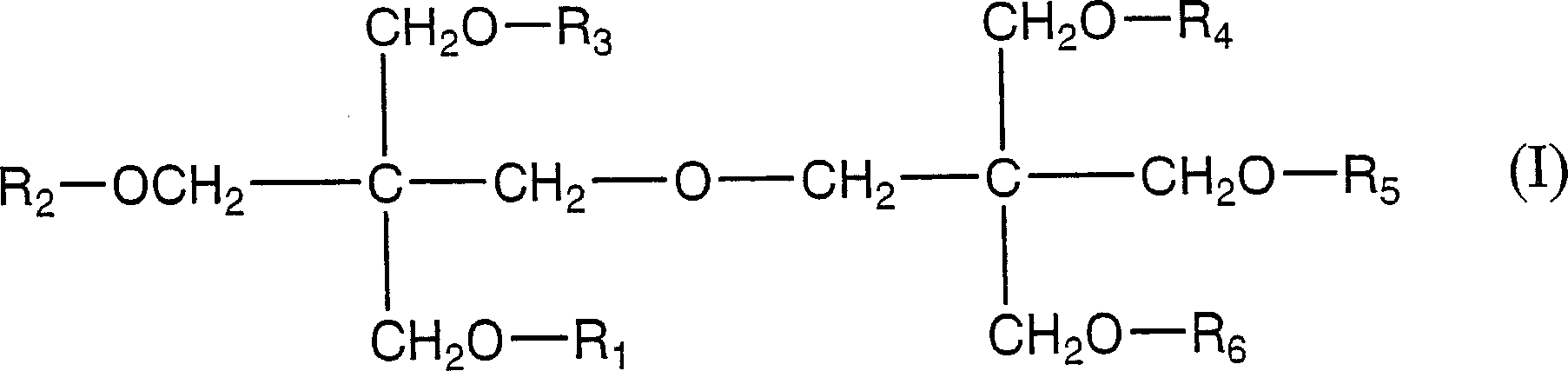

[0207] Embodiment 3, comparative example 2, comparative example 3

[0208] In Example 3, Comparative Example 2, and Comparative Example 3, the structure Ab, composition, etc. of the resin used as the binder resin (A) are shown in Formula (Y) and Table 4. In Table 4, a to d represent molar ratios.

[0209] Using the compositions shown in Table 5, evaluation was performed in the same manner as in Example 1. The results are shown in Table 6.

[0210]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com