Bonding member, method of manufacturing bonding member, and wood member bonding structure

A manufacturing method and technology for joining parts, which are applied in the connection of rods, manufacturing tools, and other manufacturing equipment/tools, etc., can solve problems such as falling, and achieve the effect of strong toughness, inhibition of relaxation or reduction of energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

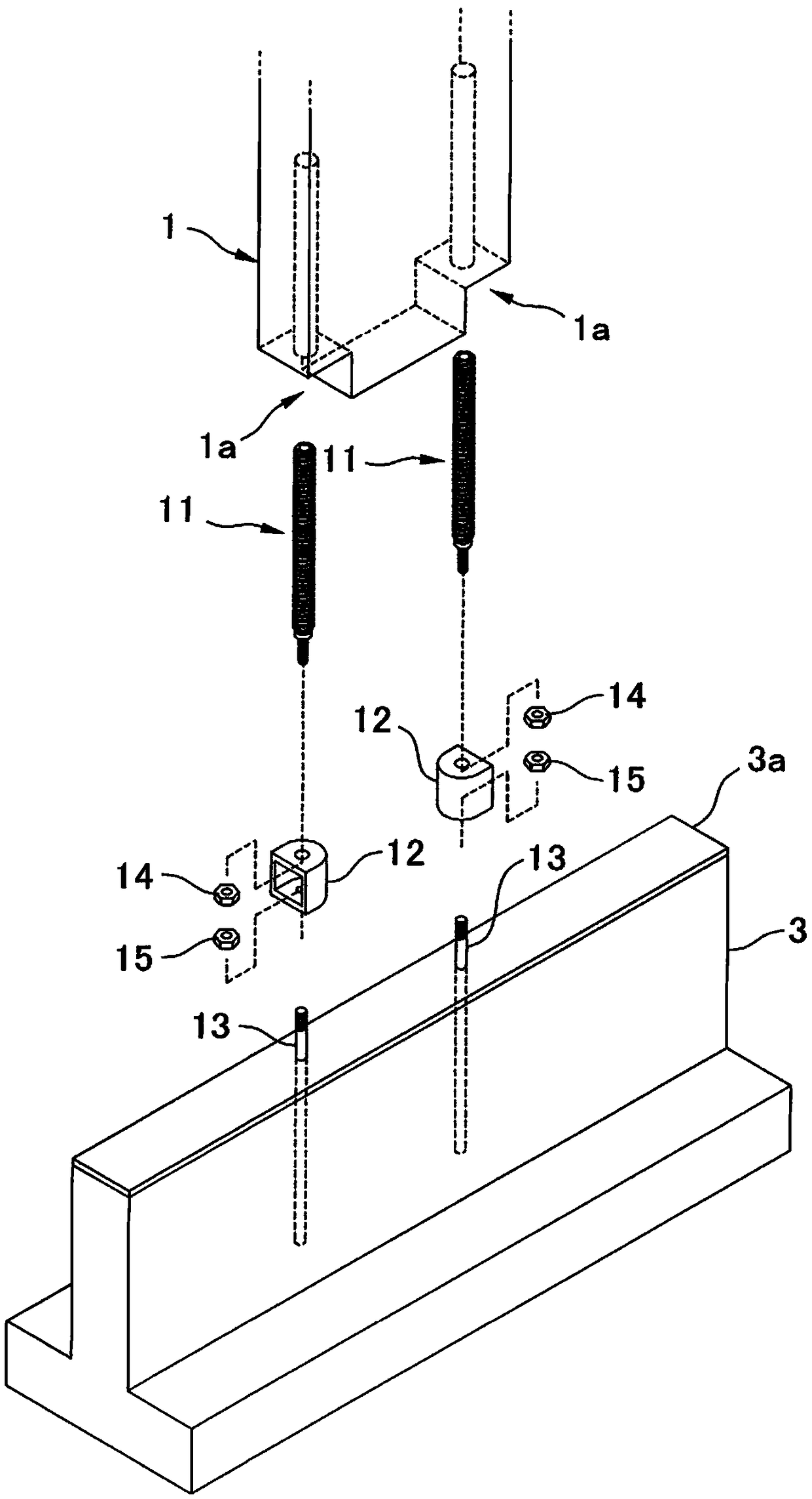

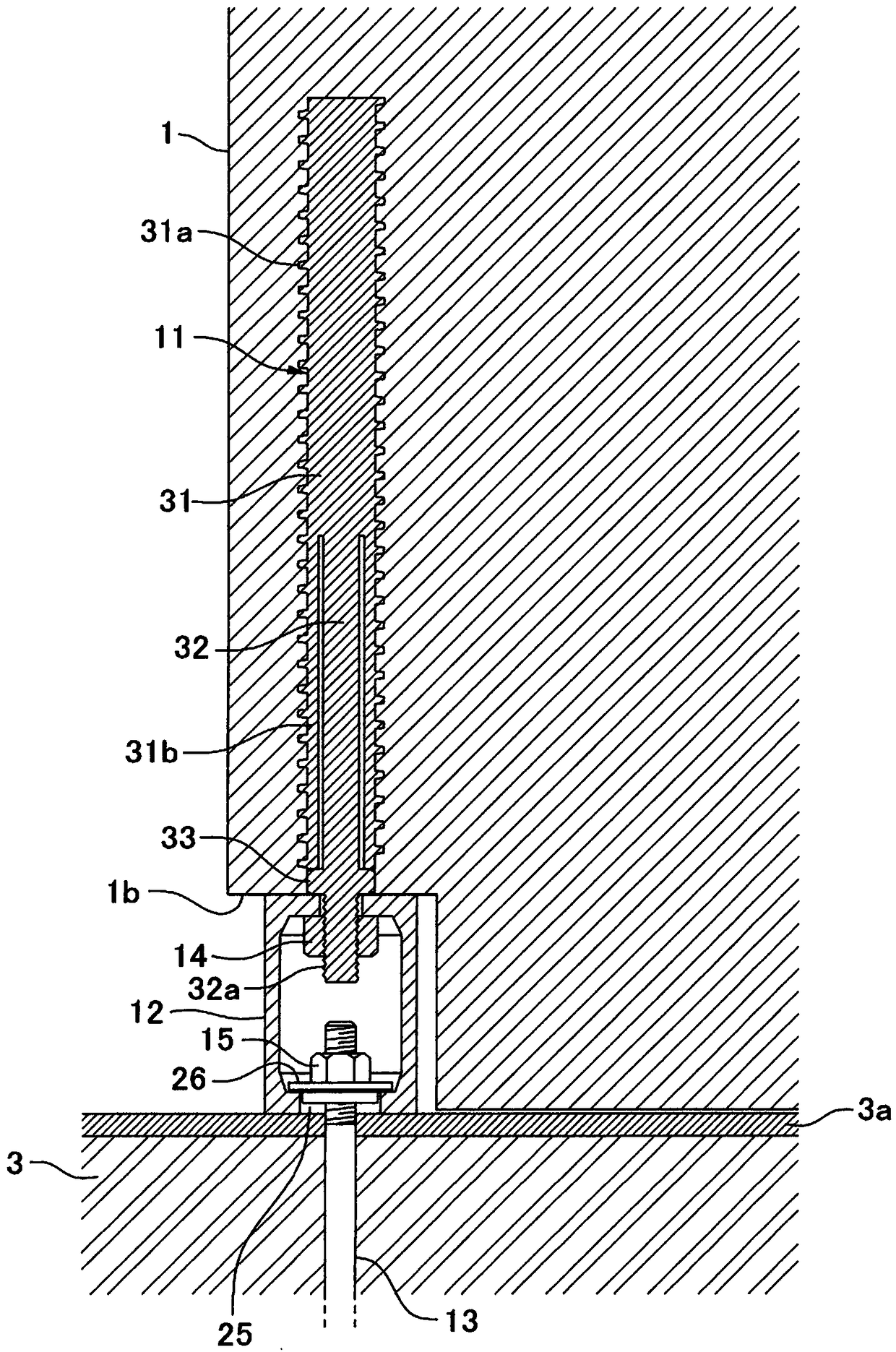

[0107] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

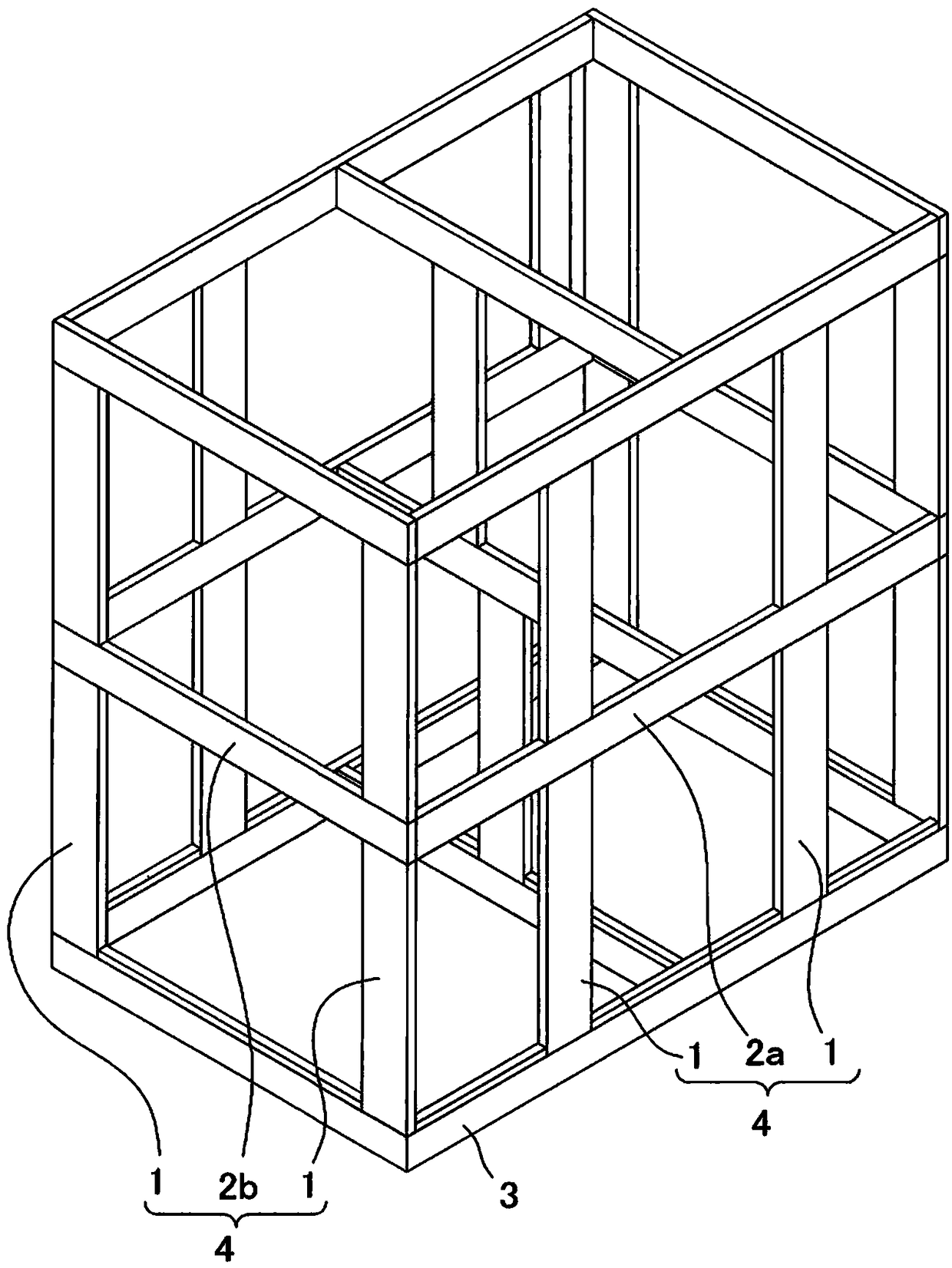

[0108] figure 1 It is a schematic perspective view showing an example of the structural skeleton of a wooden building that can use the coupling member of the present invention.

[0109] The above-mentioned structural framework has a frame frame body 4, which is formed by combining a plurality of frame frame bodies 4 on a concrete foundation 3. The frame frame body 4 connects wooden columns 1, wooden beams 2, and wooden The column 1 and the foundation 3 are joined. Each frame body 4 has a so-called continuous beam structure (梁士ちstructure) in which wooden beams 2 are placed and joined on top of wooden columns 1, and the cross section of the column 1 constituting each frame body 4 is the axis of the supported beams 2. The side of the beam 2 is long and the side is short in the direction perpendicular to the axis of the beam 2 . In addition, the cross section of the beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com