Method of manufacturing halogenated rubber like polymer

A halogenated rubber and polymer technology, applied in the field of manufacturing halogenated rubber-like polymers, can solve the problems of low reaction efficiency, large motor power consumption, low solvent recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

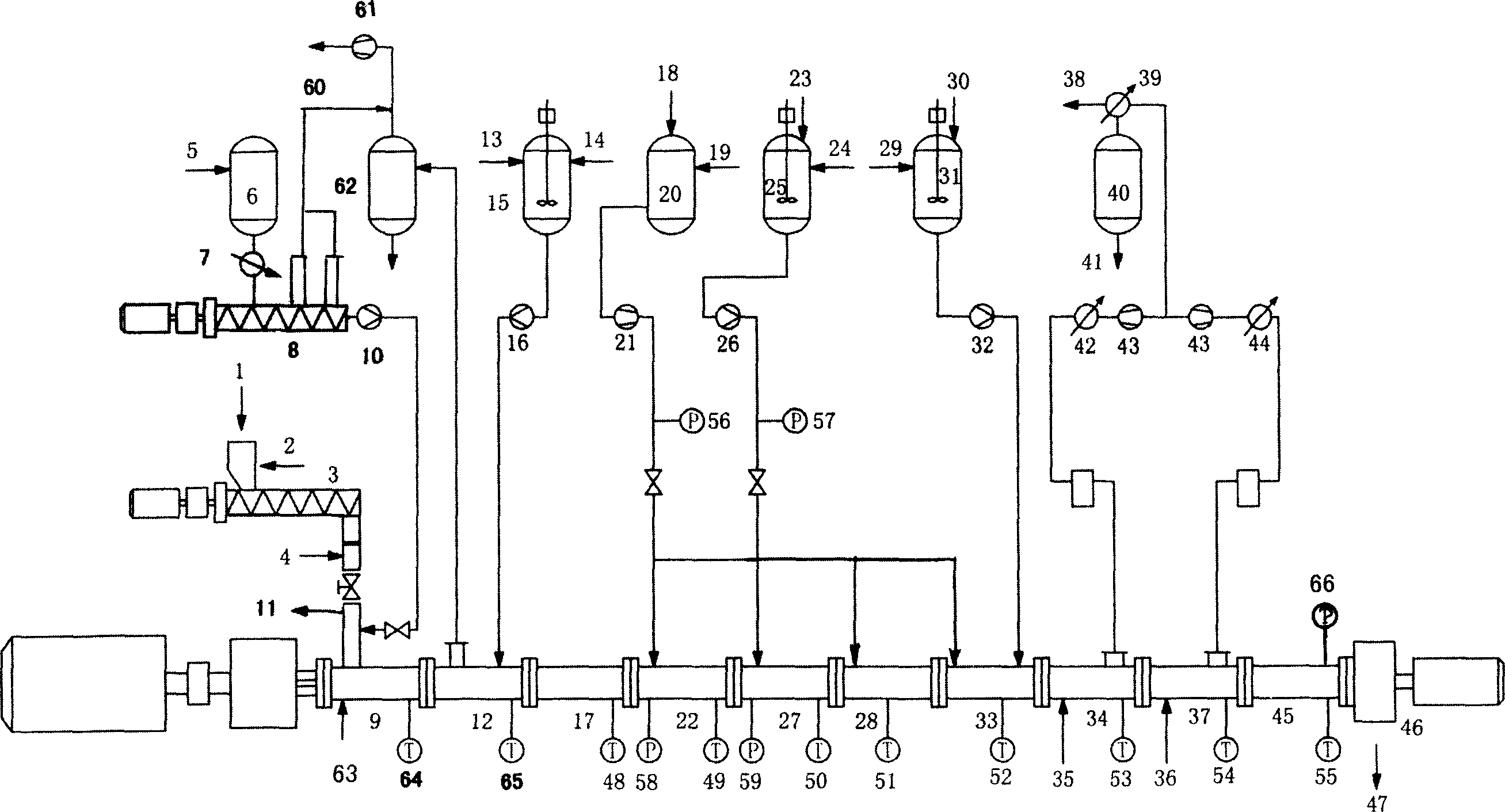

[0065] use figure 1 As shown in the process flow, the main equipment of the closed drying system in this embodiment is a reverse twin-screw extruder unit (reactor), the screw diameter is Φ36mm, and the length-diameter ratio L / D=60, except that the metering and discharging section is meshed , and the rest of the segments are non-meshing. The temperature of the cylinder is controlled in 10 sections. The cooling medium in the cylinder is 0°C white oil, and the outer cylinder is heated by an electric heating copper tile heating jacket. The raw material used is chopped solid butyl rubber pieces or long strips, and the maximum outline dimension or cross-section is less than 20mm. Add to the hopper of the screw crusher and plasticizer ③, the weight is 30kg, and its specification is a commercially available general-purpose butyl rubber with an unsaturation degree of 2% and Mooney 34. 0.01MPa pressure nitrogen gas is continuously fed into the lower part of the hopper, and the flow ra...

Embodiment 2

[0068] Use the same reactor closed drying system in Example 1. However, in this embodiment, the raw material is pumped from ⑤ into a hexane solution of butyl rubber with a solid content of 18% (wt), the dry rubber unsaturation is 2.2%, and the Mooney viscosity is 50. Under the protection of nitrogen positive pressure in the tank, the glue liquid flows out from the raw material buffer tank ⑥, is heated to 150 ℃ ~ 160 ℃ by the preheater ⑦, and enters the double-screw thickener ⑧, the solvent and a small amount of water are evaporated and recovered, The viscous solution concentrated to a solid content of about 70% is sent to the halogenation reaction system by the booster pump ⑩. Double-screw thickener ⑧ is a double-screw asynchronous co-directional concentration reactor with a diameter of Φ100 and L / D=10. Its jacket has a heating function to keep the polymer raw material at a high temperature, so as to enter the halogenation reaction and plasticize (mix) Before section ⑨, remov...

Embodiment 3

[0070] The same closed dry system and screw crushing and plasticizing machine ③ are used in Example 1, but the length-diameter ratio L / D of the screw extrusion reactor is 66, and a tail halogenation reaction section is added. The raw material is dicyclopentadiene-type EPDM rubber, the degree of unsaturation is 2.1%, and the Mooney viscosity is 75. The solid EPDM rubber is crushed into irregular blocks and strips less than 20mm in shape, and is added to the feed hopper of the screw crusher and plasticizer ③ at a frequency of 30kg per 90 minutes, and nitrogen is introduced from ② to remove the air. After ③ crushing and preliminary plasticization, it becomes a porous flocculent material, and dry nitrogen is continuously injected at ④ to reversely replace the air entrained by the material. Entering the plasticizing section ⑨ of the halogenation reactor, the material is heated and mixed with pure nitrogen, and the nitrogen containing water and oxygen is removed under reduced pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com