Poly-fibre slurry cake pretreatment

A kind of aramid pulp, pretreatment technology, applied in the direction of fiber treatment, textile and papermaking, fiber type, etc., to achieve the effect of reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

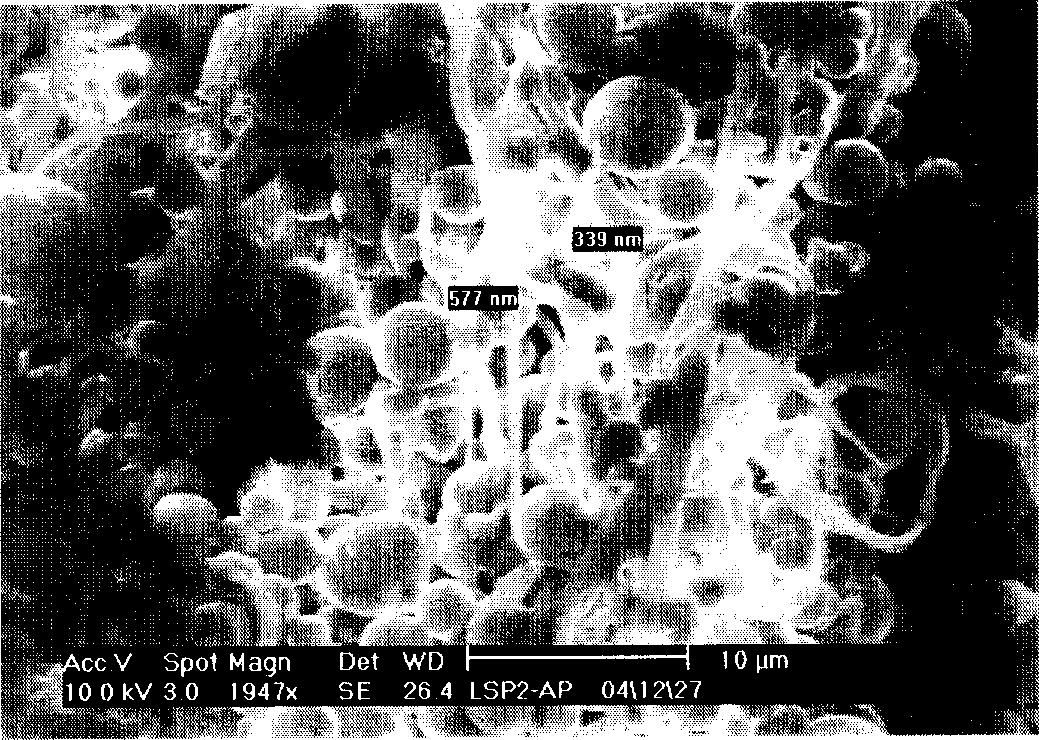

[0034] The composition of the formula is shown in Table 1. The specific preparation method is as follows: First, stir the AP in a closed high-speed mixer at high speed for 5 minutes, then add hollow glass microspheres, continue to stir at high speed for 5 minutes, and finally add lubricant, continue to stir at high speed for 10 minutes, and then AP complexes were obtained. Appearance There is no powder and liquid precipitation in the AP composite, which is a uniform and stable fiber composite. The scanning electron micrographs of the surface morphology of the AP fibers in the AP composite are shown in figure 2 ,Depend on figure 2 It can be seen that the AP microfibrils are effectively isolated by the hollow glass microspheres and the lubricant.

[0035] The AP compound is prepared with CR, NBR, HNBR, SBR or EPDM raw rubber to prepare composite materials. The formula and mixing process of the composite materials are the same as the above-mentioned "hot pressing film method"...

Embodiment 2

[0037] The formula composition is shown in Table 1, and the specific preparation method is the same as in Example 1. Appearance There is no powder and liquid precipitation in the AP composite, which is a uniform and stable fiber composite.

[0038] The AP compound and CR raw rubber are used to prepare composite materials. The formula and mixing process of the composite materials are the same as the above-mentioned "hot pressing film method". The speed is relatively fast; according to the "hot-pressed film method", the dispersion performance is evaluated as "excellent".

Embodiment 3

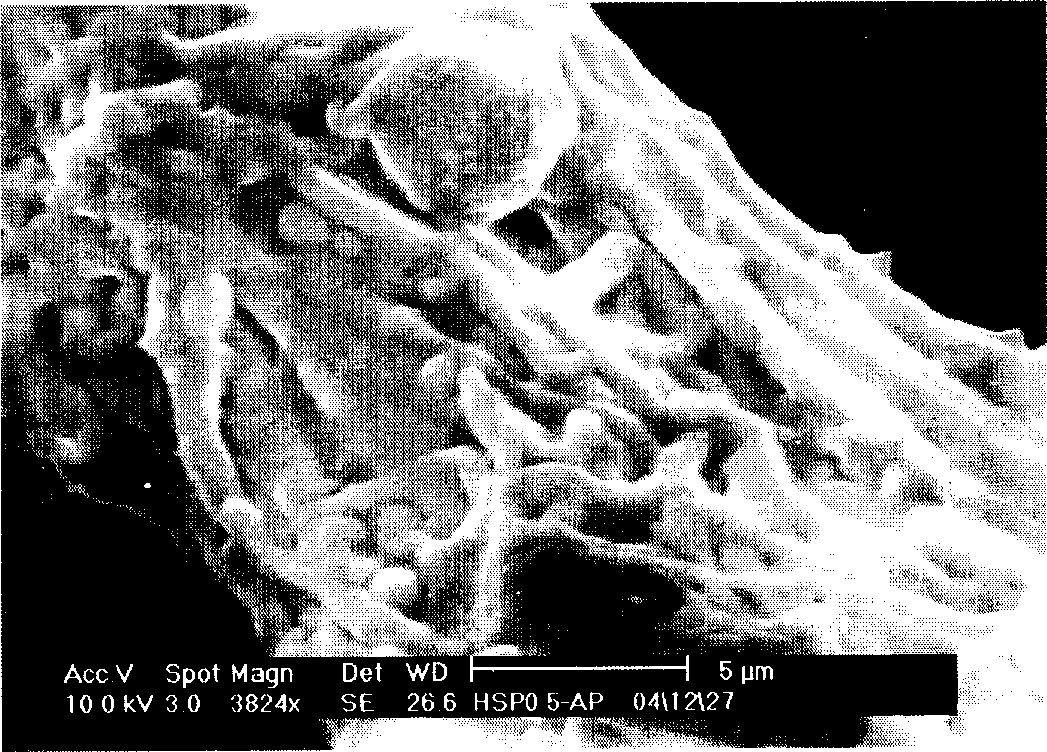

[0040] The formula composition is shown in Table 1, and the specific preparation method is the same as in Example 1. Appearance There is no powder and liquid precipitation in the AP composite, which is a uniform and stable fiber composite. The scanning electron micrographs of the surface morphology of the AP fibers in the AP composite are shown in image 3 ,Depend on image 3 It can be seen that the AP microfibrils are effectively isolated by the hollow glass microspheres and the lubricant.

[0041] The AP compound is prepared with CR, NBR, HNBR, SBR or EPDM raw rubber to prepare composite materials. The formula and mixing process of the composite materials are the same as the above-mentioned "hot pressing film method". There is no dust flying in the middle, and the fiber mixing and dispersion speed is relatively fast; according to the "hot-pressed film method", the dispersion performance evaluation is "excellent".

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com