Single alloy compressing-diffusing metal hydride heat pump/refrigerating method and system

A refrigeration method and refrigeration system technology, applied in energy-saving heating/cooling, refrigerators, refrigeration and liquefaction, etc., can solve the problems of low efficiency and reliability, considerable loss of heat/cooling capacity, and low COP, and achieve Good economy and practicability, improving energy utilization efficiency and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

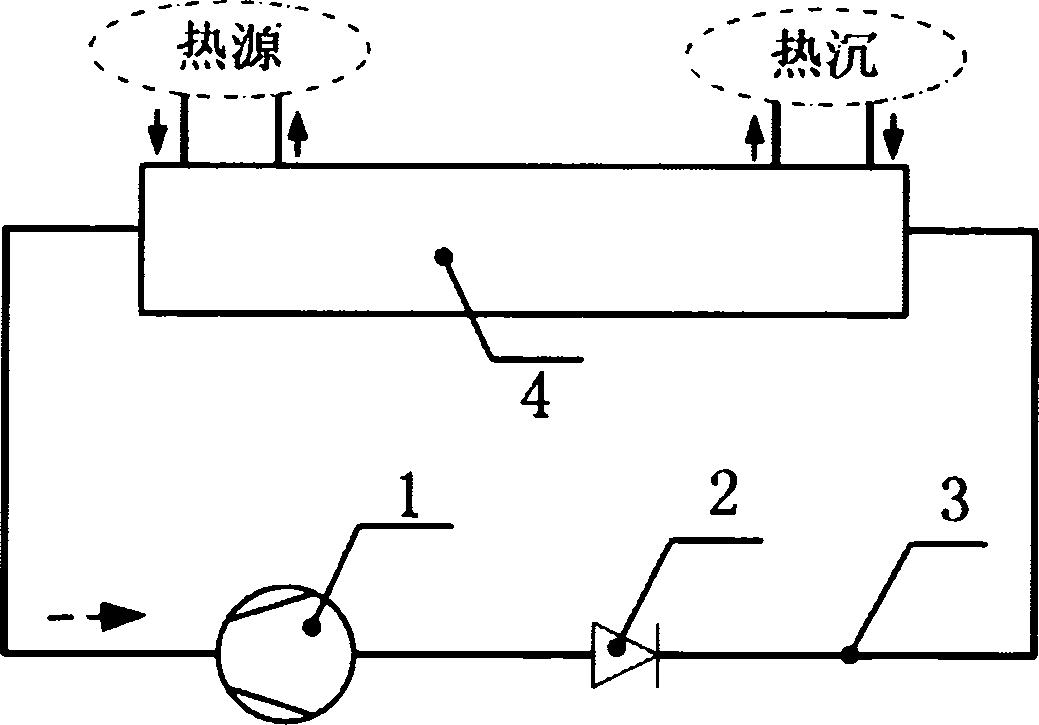

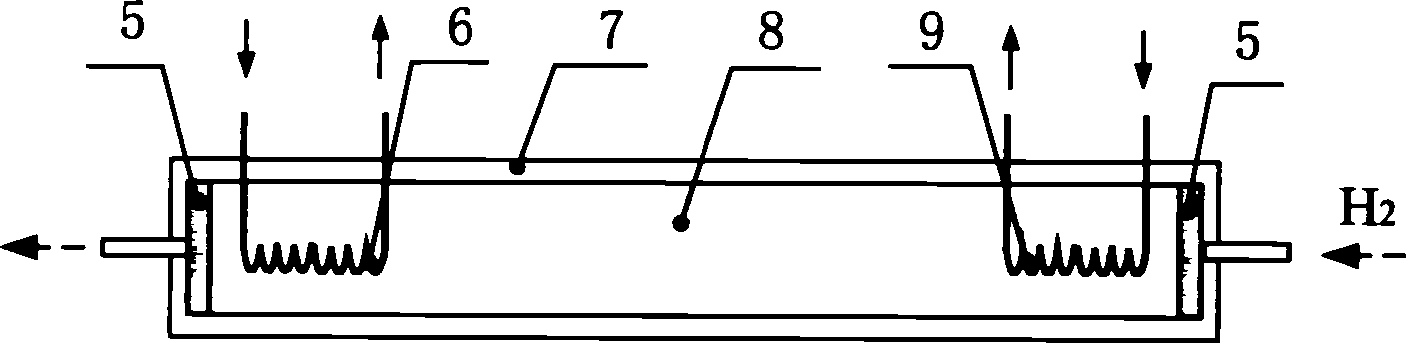

[0018] Such as figure 1 , 2 As shown, the system of the present invention includes a compressor 1, a one-way valve 2, a hydrogen pipeline 3 and a diffused bed 4, and the diffused bed 4 further includes a microporous filter 5, a low-temperature heat exchanger 6, a heat insulating outer wall 7 of the bed body, and a metal hydrogenation Material powder 8 and high temperature heat exchanger 9.

[0019] The inlet and outlet of the compressor 1 are connected to the inlet and outlet of the diffused bed 4 through the hydrogen pipeline 3, and a check valve 2 is installed on the outlet pipeline of the compressor 1 to prevent hydrogen from flowing backward. The diffused bed 4 is surrounded by the heat-insulating outer wall 7 of the bed body as a whole. A high-temperature heat exchanger 9 is installed near the entrance of the diffused bed 4 and con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com