Negative light-sensitive resin composition

A technology of photosensitive resin and composition, applied in optics, opto-mechanical equipment, nonlinear optics, etc., can solve the problems of volume shrinkage, slow curing speed, difficult to achieve high transmittance of interlayer insulating film, etc., and achieve excellent performance , The effect of improving sensitivity, residual film rate, and excellent UV transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (manufacture of acrylic copolymer)

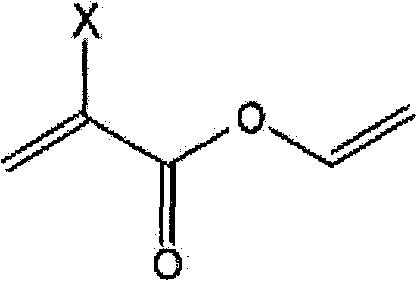

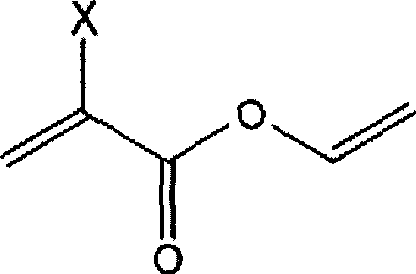

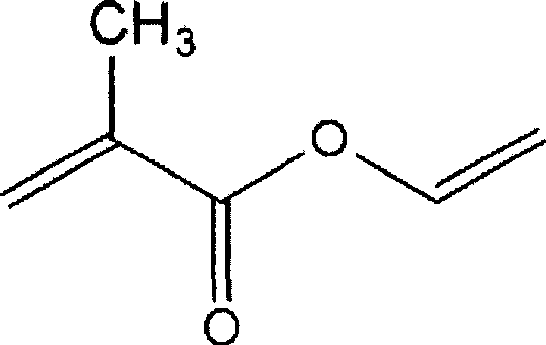

[0066] Add 10 parts by weight of 2,2-azobis(2,4-dimethylvaleronitrile), 200 parts by weight of propylene glycol monomethyl ether acetate, 10 parts by weight Parts of methacrylic acid, 25 parts by weight of glycidyl methacrylate, 35 parts by weight of allyl methacrylate of the following chemical formula 1a, and 30 parts by weight of styrene were nitrogen exchanged and then slowly stirred. The temperature of the reaction solution was raised to 62° C. and maintained at this temperature for 5 hours to produce a polymer solution containing an acrylic copolymer.

[0067] The acrylic copolymer produced as above was added dropwise to 5000 parts by weight of hexane, separated by filtration, and then 200 parts by weight of propionate was added thereto, heated to 30°C, and the concentration of the solid content was: 45% by weight, a polymer solution having a polymer weight average molecular weight of 11,000. In this case, the weight average m...

Embodiment 2

[0073] In the manufacture of the acrylic copolymer of the above-mentioned embodiment 1, using 15 parts by weight of glycidyl methacrylate and 45 parts by weight of allyl methacrylate of the chemical formula 1a, the solid of the manufactured acrylic copolymer Except that the density|concentration of a component is 45 weight%, and a weight average molecular weight is 13000, it implemented by the method similar to said Example 1, and manufactured the negative photosensitive resin composition coating solution.

Embodiment 3

[0075] In the manufacture of the acrylic copolymer of the above-mentioned Example 1, 65 parts by weight of allyl methacrylate of chemical formula 1a, 5 parts by weight of methacrylic acid, 5 parts by weight of glycidyl methacrylate, 25 parts by weight styrene by weight to make a polymer solution, add 250 parts by weight of propionate to make a solid concentration of 45% by weight and an acrylic copolymer with a weight-average molecular weight of 15000, in addition, through the above-mentioned The same method as in Example 1 was carried out to manufacture a negative photosensitive resin composition coating solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com