Method for accomplishing pseudo color reinforced metallographic microstructure based on digital image technology

A microstructure and digital image technology, which is applied in microscopes, image data processing, image data processing, etc., can solve the problems of unstable effects, environmental pollution, expensive equipment, etc., and achieve the effect of easy popularization, no pollution, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

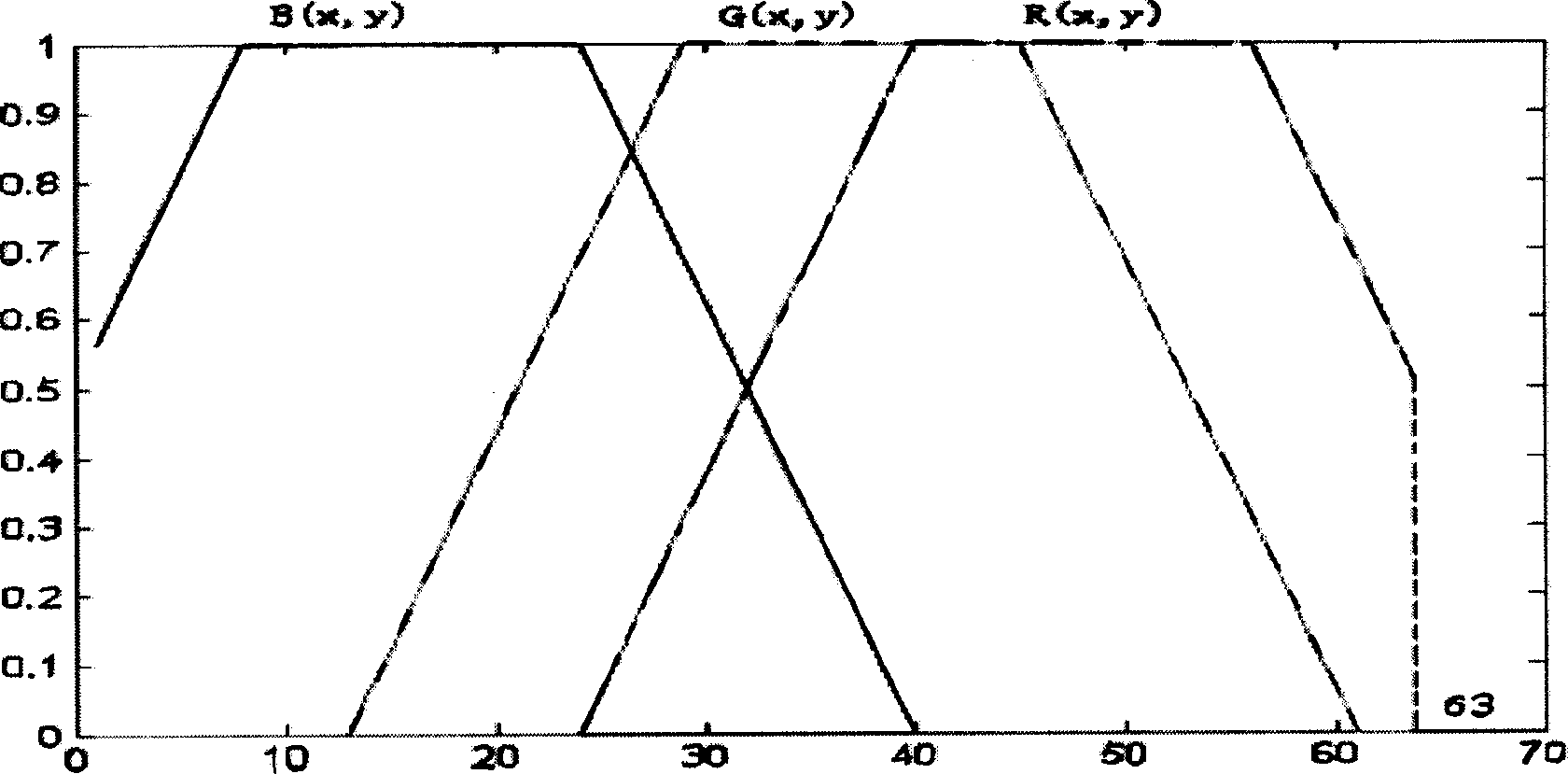

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Figure 4a It is a grayscale image (500×) of the quenched structure of high-speed steel W18Cr4V. White massive carbides and white bone-like carbides (eutectic ledeburite) are distributed on the gray martensite-retained austenite matrix. There are quenched troostite and quenched sorbite (eutectoid product of 6 phases) in the form of black lumps, in which the gray difference between the martensite-retained austenite matrix and the carbide is small, and it is difficult to distinguish by gray; Figure 4b yes Figure 4a False-color image of , in which massive and skeletal primary carbides are rendered in dark red, martensite-retained austenite is rendered in light red, and the color difference is obvious; the blue area is black tissue, and the dark blue quenched The troostite and the lake-blue quenched sorbite are magically separated, and the orange dots are secondary carbides; the martensite-retained austenite is red at a rough glance, but there are still shades...

Embodiment 2

[0056] Example 2: Figure 5a It is a grayscale image (500×) of the quenched and burnt structure of Cr12 steel. Black acicular coarse tempered martensite is distributed on the gray coarse-grained austenite matrix, and white massive granular carbides are accumulated at the black grain boundaries. Eutectic ledeburite produced by overburning; Figure 5b Figure 5a The pseudo-color image of the blue grain boundary outlines the coarse austenite grains into an orange-red matrix, and the distributed eutectic ledeburite carbides turn into deep red, and the carbides and austenite are separated by color; on the matrix The distributed tempered martensite turns dark blue.

Embodiment 3

[0057] Example 3: Figure 6a It is a grayscale image (400×) of the quenched and medium-temperature tempered structure of cast steel ZG50 shrinkage porosity. On the gray tempered troostite matrix, there are white massive (quenched and heated) undissolved ferrites, and there are a lot of ( Unhardened) black mass quenched troostite and white reticular proeutectoid ferrite; Figure 6b yes Figure 6a False-color images of tempered troostite become lake blue, undissolved ferrite dark red, quenched troostite dark blue, pro-eutectoid ferrite red or orange; tempered troostite Body and quenched troostite are clearly distinguished in the false color image.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com