Method for preparing copper conductor for plane display substrate

A flat-panel display, copper wire technology, used in semiconductor/solid-state device manufacturing, semiconductor device, conductive pattern formation, etc., can solve problems such as inability to form metal layers naturally, component operating channel damage, metal wire short-circuits, etc., to avoid short-circuit and Component manipulation channel damage, increased adhesion, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

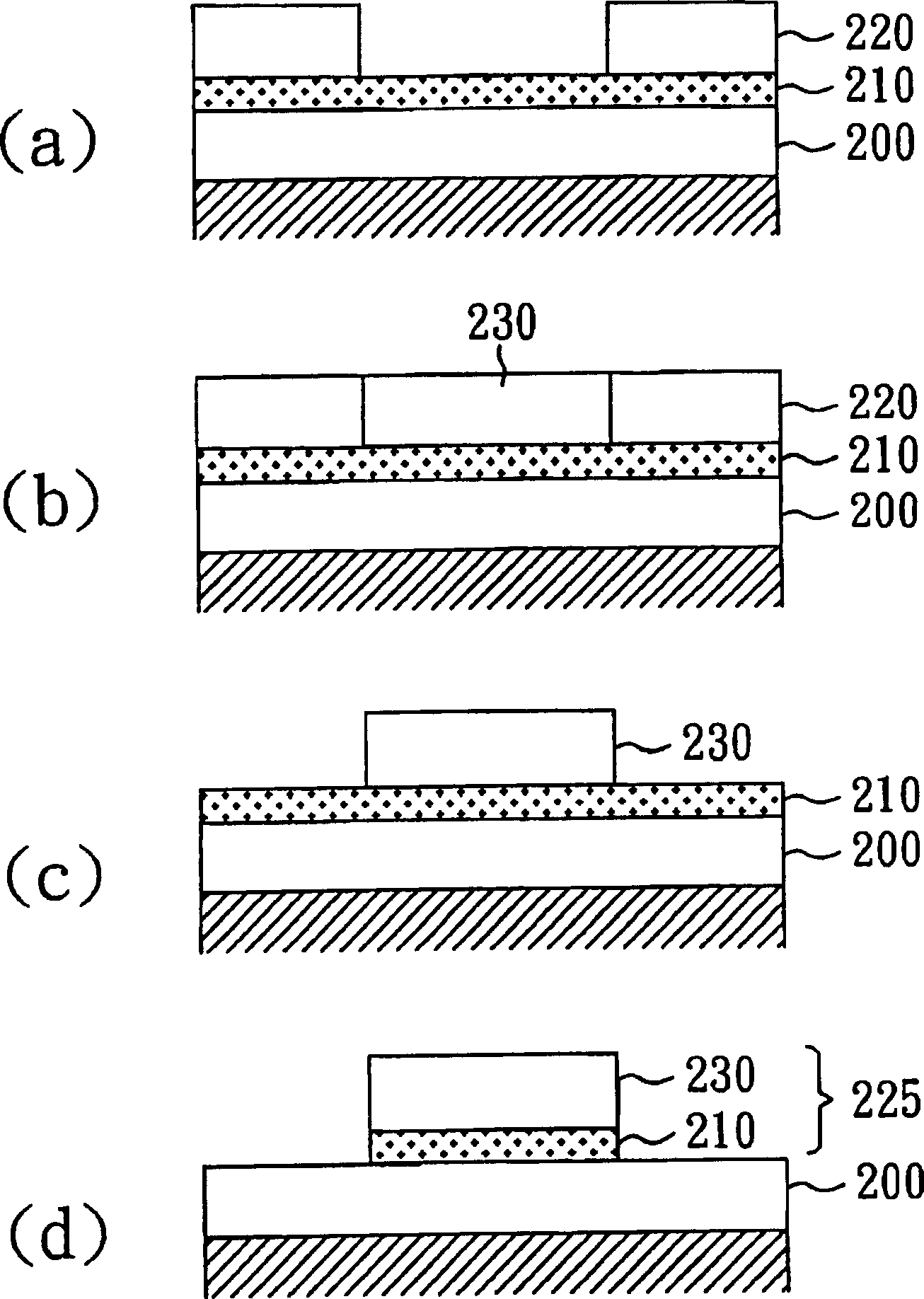

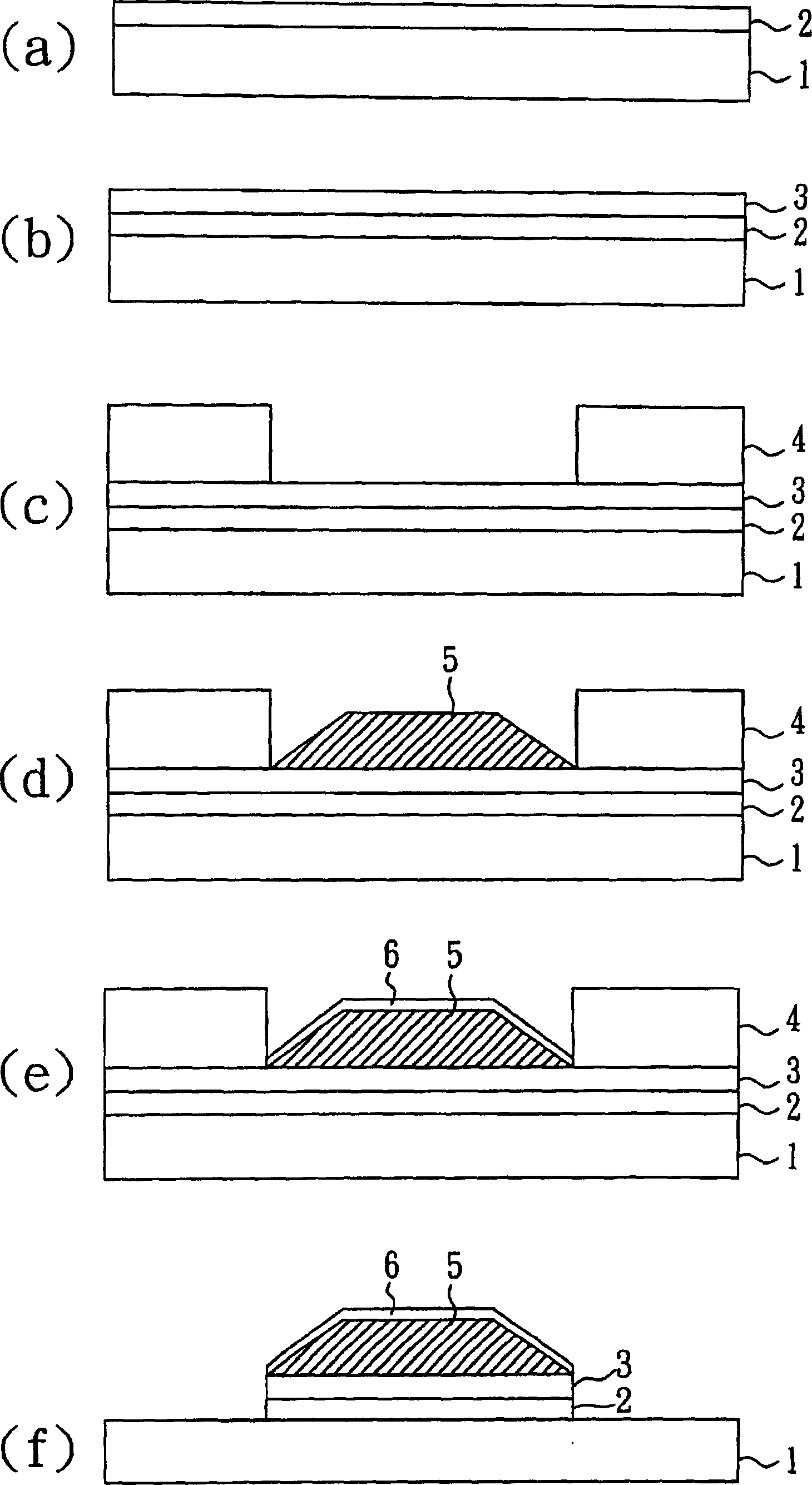

[0035] see figure 2 , figure 2 It is a schematic flow diagram of the copper wire preparation of a preferred embodiment of the present invention. Firstly, an active matrix driven planar display substrate 1 is provided, and a first barrier layer 2 of silicon nitride (TiN) material is deposited on the surface of the substrate 1 by physical vapor deposition, that is, the formation of figure 2 (a) Substrate structure shown. Next, in this embodiment, a physical vapor deposition process is also used to deposit a copper metal seed layer 3 on the surface of the first barrier layer 2 to form a figure 2 (b) Substrate structure shown. Immediately, a positive photoresist layer 4 is deposited on the surface of the copper seed layer 3, and a photomask is used for exposure and development to form a patterned photoresist layer 4, wherein the formed structure is as follows figure 2 (c) shown.

[0036] Depend on figure 2 As shown in (d), the present embodiment obtains the substrate 1...

Embodiment 2

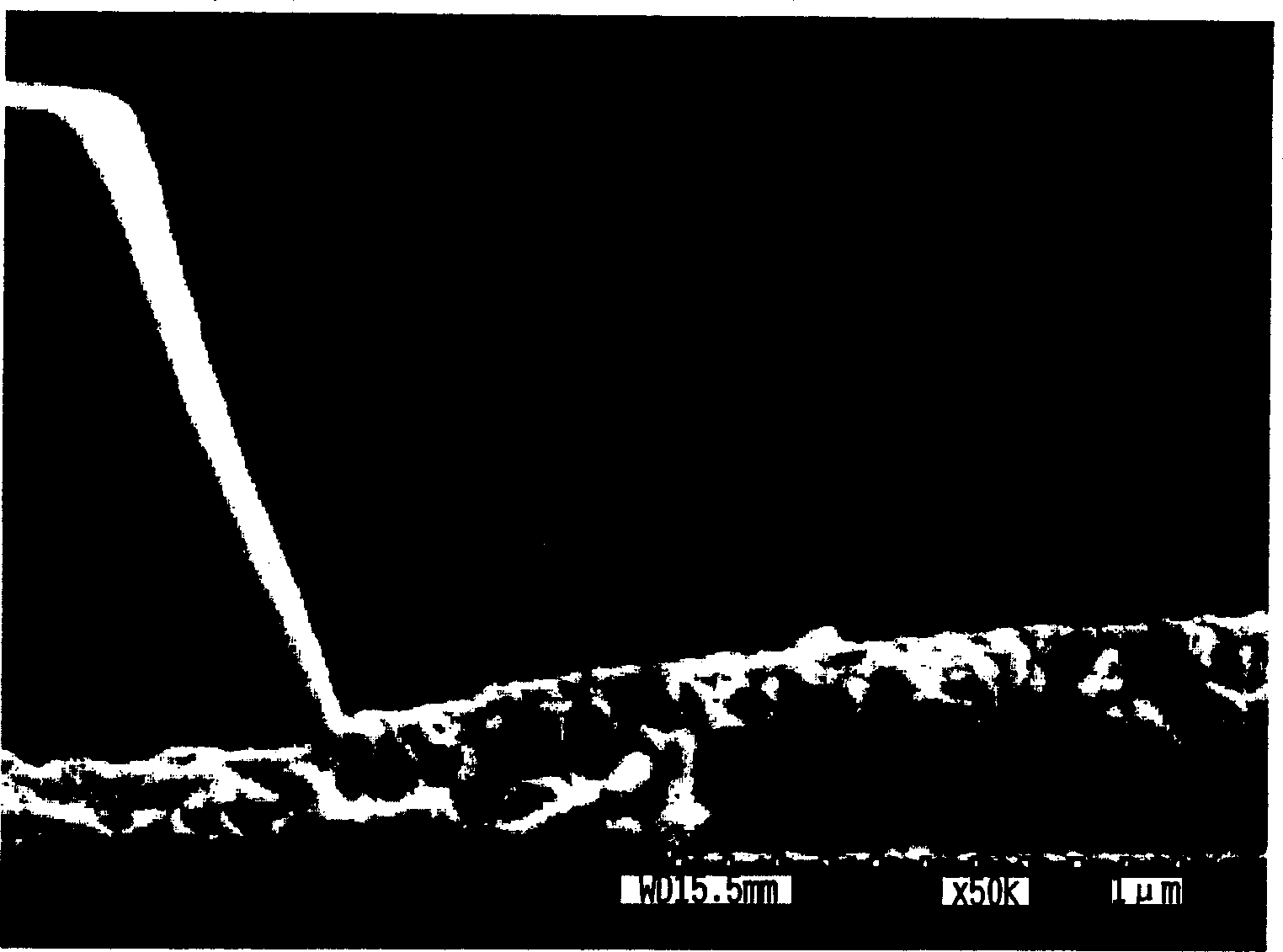

[0040] The preparation method of the copper wire in this embodiment is roughly the same as that shown in Example 1, the only difference being that 90 ppm polydisulfide sodium sulfonate surfactant is added to the electrolyte to form a copper wire layer with an inclination angle 5 , see image 3 The electron micrograph picture shown (the layer on the right side of the figure with an inclination angle of about 25° is the copper wire layer 5 of this embodiment, and the layer on the left side of the figure is the photoresist layer 4 of this embodiment) . In addition, the electroplating condition of the present embodiment is 8ASF (A / ft 2 ), a current density of 100 seconds, and a reaction temperature of 25°C.

Embodiment 3

[0042] The preparation method of the copper wire of this embodiment is roughly the same as that shown in Example 1, the difference is only that 0.75ppm polydisulfide sodium propane sulfonate surfactant and 10ppm polyethylene glycol are added to the electrolyte to form a The copper wire layer 5 with an inclination angle of about 50°. . Therefore, when a little polyethylene glycol and a small amount of sodium polydisulfide dipropane sulfonate are added to the electrolytic solution, the copper wire layer 5 with a complete inclination angle and a flat surface layer can be electroplated and deposited. The electroplating condition of the present embodiment is 10ASF (A / ft 2 ), a current density of 70 seconds, and a reaction temperature of 30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com