Method and apparatus for producing materials of double metal shaft sleeve parts

A bimetallic shaft and production method technology, which is applied to the production of bimetallic shaft sleeve parts and materials and the field of equipment, can solve the problems of increasing the processing cycle and product production cost, affecting the mechanical properties of the shaft sleeve, and not being able to perform high-performance parts, etc. The effect of facilitating automatic assembly, improving mechanical technical performance and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

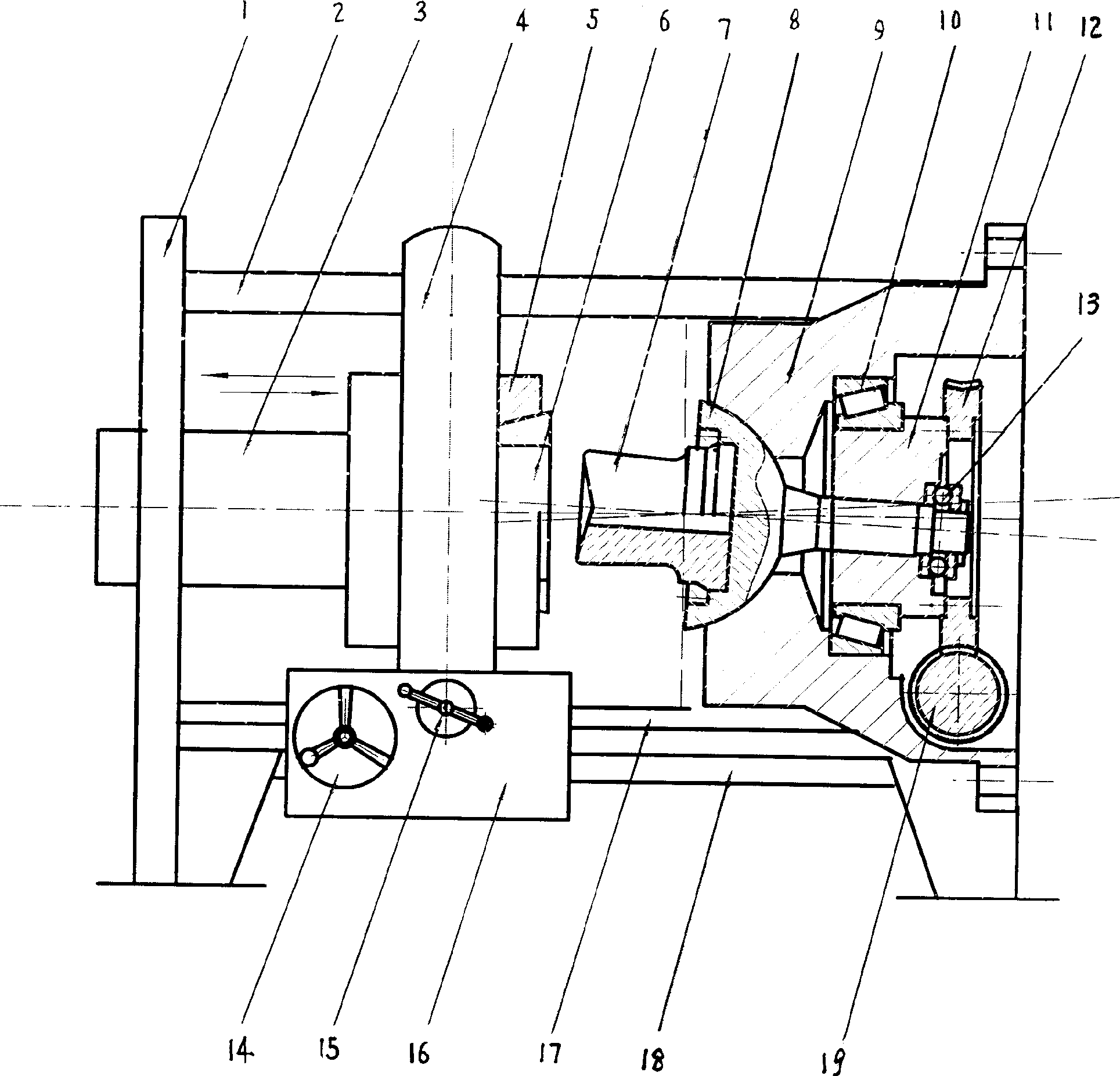

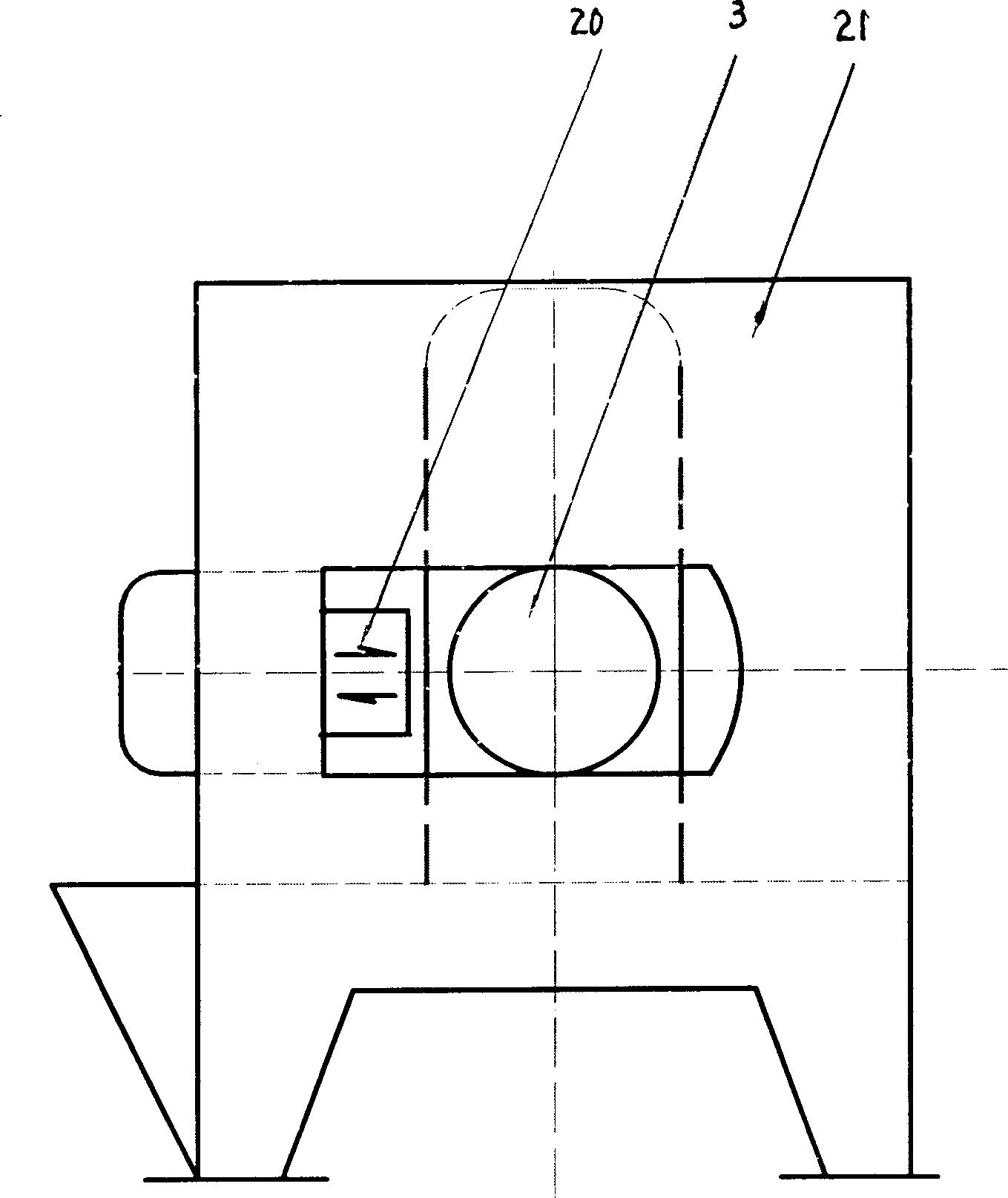

[0017] specific implementation plan

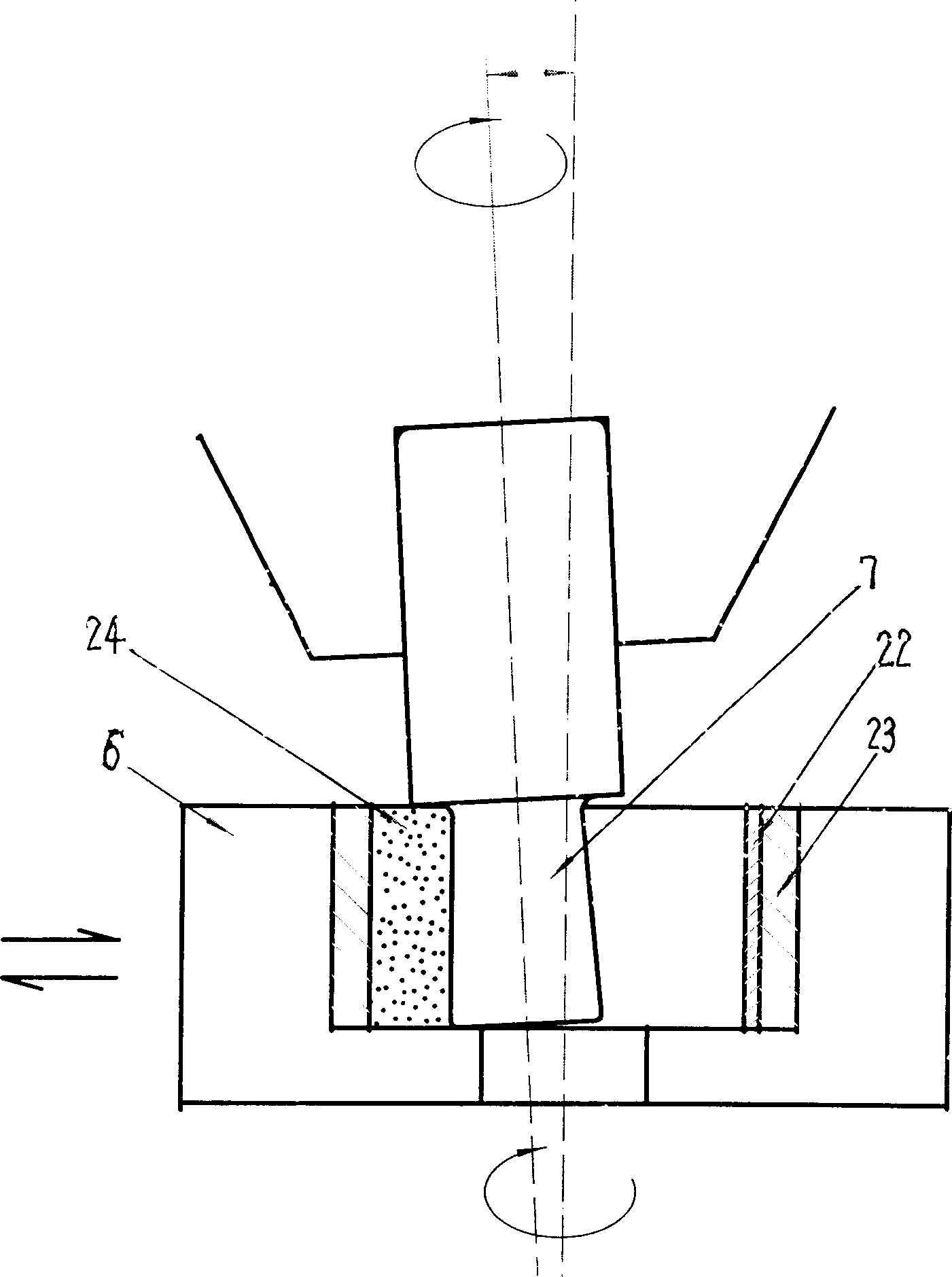

[0018] Use the seamless steel pipe as the steel backing of the metal bushing, first select and transversely cut the seamless steel pipe according to the length and diameter of the metal bushing to be used as the steel backing of the metal bushing. Then, the inner wall of the steel backing that meets the requirements is cleaned, and the cleaning solution used in the cleaning process is lye. Put the non-environmentally polluting lye with a concentration of 3% to 6% into the ultra-wave cleaning machine, and then put it into the steel backing to be cleaned for cleaning. Then put into the technological mandrel in the steel backing, put copper alloy powder into the design gap between the technological mandrel and the inner wall of the steel pipe, and then send it into a protective atmosphere together (the composition of the protective atmosphere is nitrogen 30%, Sintering is carried out in a sintering furnace with 70% hydrogen gas, the sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com