Electrophoretic display and process for its manufacture

An electrophoresis and electrode layer technology, which is applied in static indicators, electrical recording processes and instruments using photoelectrophoresis, etc., can solve the problems of low effective load of pigment particles, poor scratch resistance, and reduced contrast, and achieve easy handling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] I. Preparation of Microcups

[0047] I(a) Preparation of microcups by compression molding

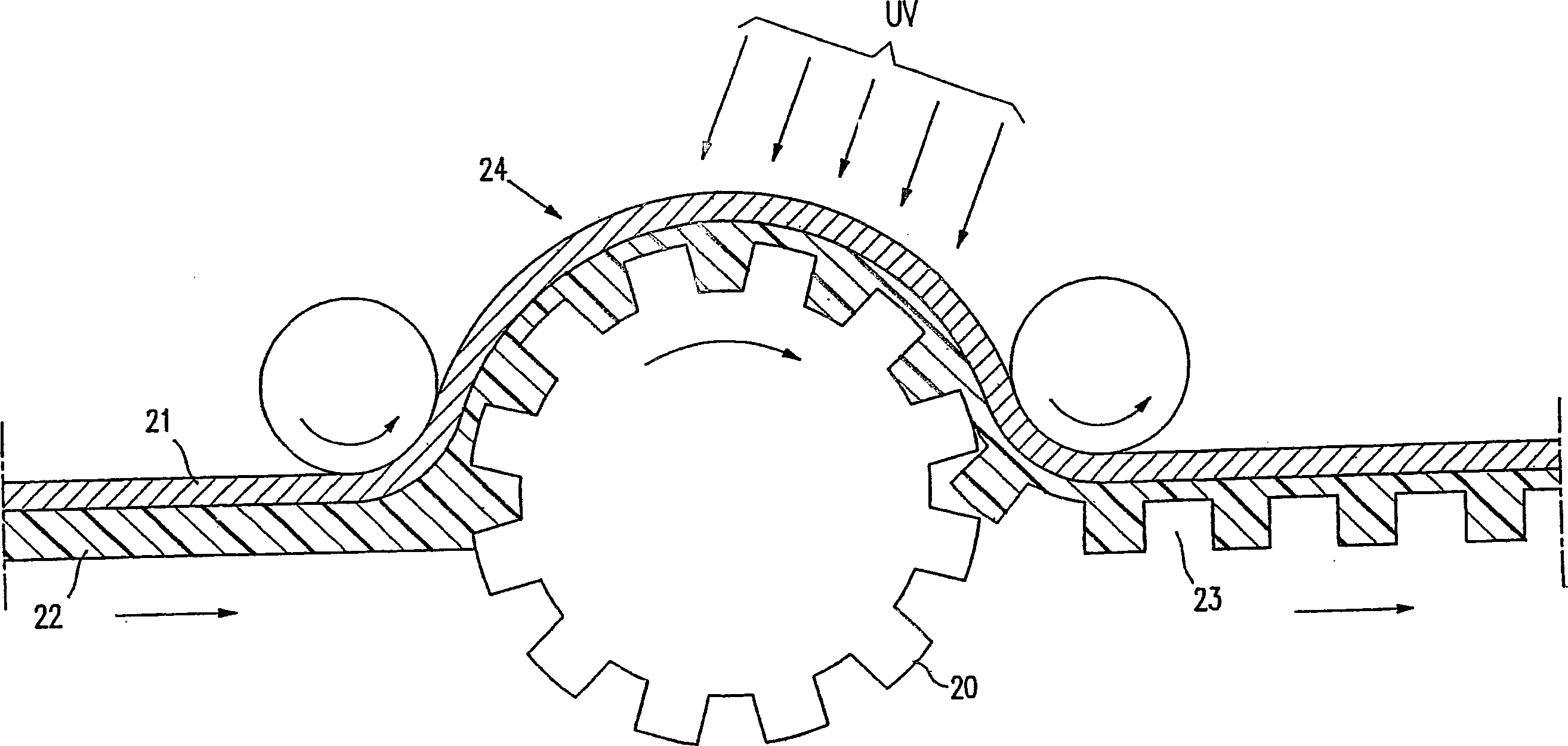

[0048] The process steps are shown in Figure 2a and Figure 2b middle. Punch (20) can be placed on mesh belt (24) ( Figure 2a ) or under the mesh belt ( Figure 2b ). A transparent conductive film (21) is formed on a glass plate or a plastic substrate to make a transparent conductive substrate. A composition (22) comprising a thermoplastic resin, a thermosetting resin, or a precursor thereof is then coated on the conductive film. The thermoplastic or thermosetting precursor layer is embossed with a male die in the form of a roll, plate or belt at a temperature above the glass transition temperature of the thermoplastic or thermosetting precursor layer.

[0049] The thermoplastic or thermoset precursors used to make the microcups can be multifunctional acrylates or methacrylates, vinyl ethers, epoxides and oligomers or polymers thereof, and the like. Most preferred are m...

Embodiment 1

[0129] Fabrication of microcups by micromolding

[0130] The composition shown in Table 1 was coated on Mylar by using a nickel-chromium Bird type (bird type) film applicator with an opening of 3 mils. TM J101 / 200 model. The solvent was evaporated so as to leave a viscous film with a Tg below room temperature.

[0131] Numbering

[0132] A prepatterned stencil from Photo Stencil (Colorado Springs, CO) was used as the punch for micromolding, while Frekote from Henkel TM 700-NC was used as a release agent. The coated film was then embossed at room temperature through a stencil using a pressure roller. Then through Mylar TM film and utilize Loctite Zeta 7410 TM The coating was cured by UV light for about 20 minutes in the exposure device equipped with a metal fluoride lamp with an intensity of 80 mW / cm at 365 nm 2 . The molded film was then demolded to reveal well-defined microcups, as measured by optical profilometry and microscopy ( Figures 4a-4c ), the si...

Embodiment 2

[0134] Preparation of microcups

[0135] Compositions containing solid oligomers, monomers and additives are shown in Table 2. The glass transition temperature of the mixture is also below room temperature. Deposit the sticky coating on Mylar as previously described TM on top of the J101 / 200 template. Molding is performed at 60° C. using a heated press roll or a laminator. High resolution microcups (100-400 dpi) with a well-defined depth range of 5-30 microns were produced.

[0136] Numbering

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com