Pressure-sensitive fingerprint adhesive and its prepn

A technology of pressure sensitivity and fingerprint, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the problem of high raw material cost, achieve the effect of reduced raw material cost and simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

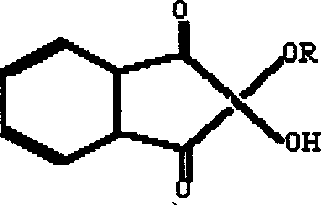

Image

Examples

example 1

[0027] Prepare the viscous polymer with the following components (unit: gram)

[0028] Natural Rubber Emulsion 41.0

[0029] Acrylic 1.0

[0030] Vinyl acetate 10.0

[0031] Hydroxypropyl Acrylate 16.0

[0032] water 28.0

[0033] Potassium persulfate 0.01

[0034] Rosin modified resin 3.2

[0035] Sodium lauryl sulfate 0.1

[0036] Dodecyl Mercaptan 0.05

[0037] Preparation of modified natural rubber emulsion grafted with acrylic acid: in the water phase, add emulsifier sodium lauryl sulfate, under the trigger of potassium persulfate, under the regulation of dodecyl mercaptan, acrylic acid, vinyl acetate, Isooctyl acrylate was emulsion polymerized at 50° C. for 8 hours, and then added to the natural rubber emulsion to obtain a modified natural rubber emulsion grafted with acrylic acid. Add tackifier rosin modified resin to the modified natural rubber latex to prepare acrylic acid grafted modified natural rubber latex.

[0038] 546 grams of ninhydrin are dissolved in...

example 2

[0040] Prepare the viscous polymer with the following components (unit: gram)

[0041] Natural Rubber Emulsion 40.0

[0042] Acrylic 1.2

[0043] Vinyl acetate 6.0

[0044] Butyl acrylate 20.0

[0045] water 19.6

[0046] Potassium persulfate 0.45

[0047] Epoxy resin 6.4

[0048] Sodium lauryl sulfate 0.4

[0049] Dodecyl Mercaptan 0.2

[0050] Preparation of modified natural rubber emulsion grafted with acrylic acid: In the water phase, add emulsifier sodium lauryl sulfate, under the trigger of potassium persulfate, under the regulation of dodecyl mercaptan, acrylic acid, vinyl acetate, acrylic acid The butyl ester was emulsion polymerized at 65° C. for 2.5 hours, and then added to the natural rubber emulsion to obtain a modified natural rubber emulsion grafted with acrylic acid. In the modified natural rubber latex, tackifier rosin modified resin and epoxy resin are added to prepare the modified natural rubber latex grafted with acrylic acid.

[0051] Preparation o...

example 3

[0053] Prepare the viscous polymer with the following components (unit: gram)

[0054] Natural Rubber Emulsion 40.0

[0055] Acrylic 1.0

[0056] Vinyl acetate 7.0

[0057] Isooctyl acrylate 15.0

[0058] water 27.2

[0059] Ferrous sulfate 0.24

[0060] Epoxy resin 6.4

[0061] Sodium formylsulfonate 1.0

[0062] Dodecyl Mercaptan 0.2

[0063] Preparation of modified natural rubber emulsion grafted with acrylic acid: in the water phase, add emulsifier sodium formylsulfonate, under the trigger of potassium persulfate, under the regulation of dodecyl mercaptan, acrylic acid, vinyl acetate, acrylic acid iso The octyl ester was emulsion polymerized at 80° C. for 1.5 hours, and then added to the natural rubber emulsion to obtain a modified natural rubber emulsion grafted with acrylic acid. In the modified natural rubber latex, a tackifier epoxy resin is added to obtain a modified natural rubber latex grafted with acrylic acid.

[0064] Preparation of pressure-sensitive fing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com