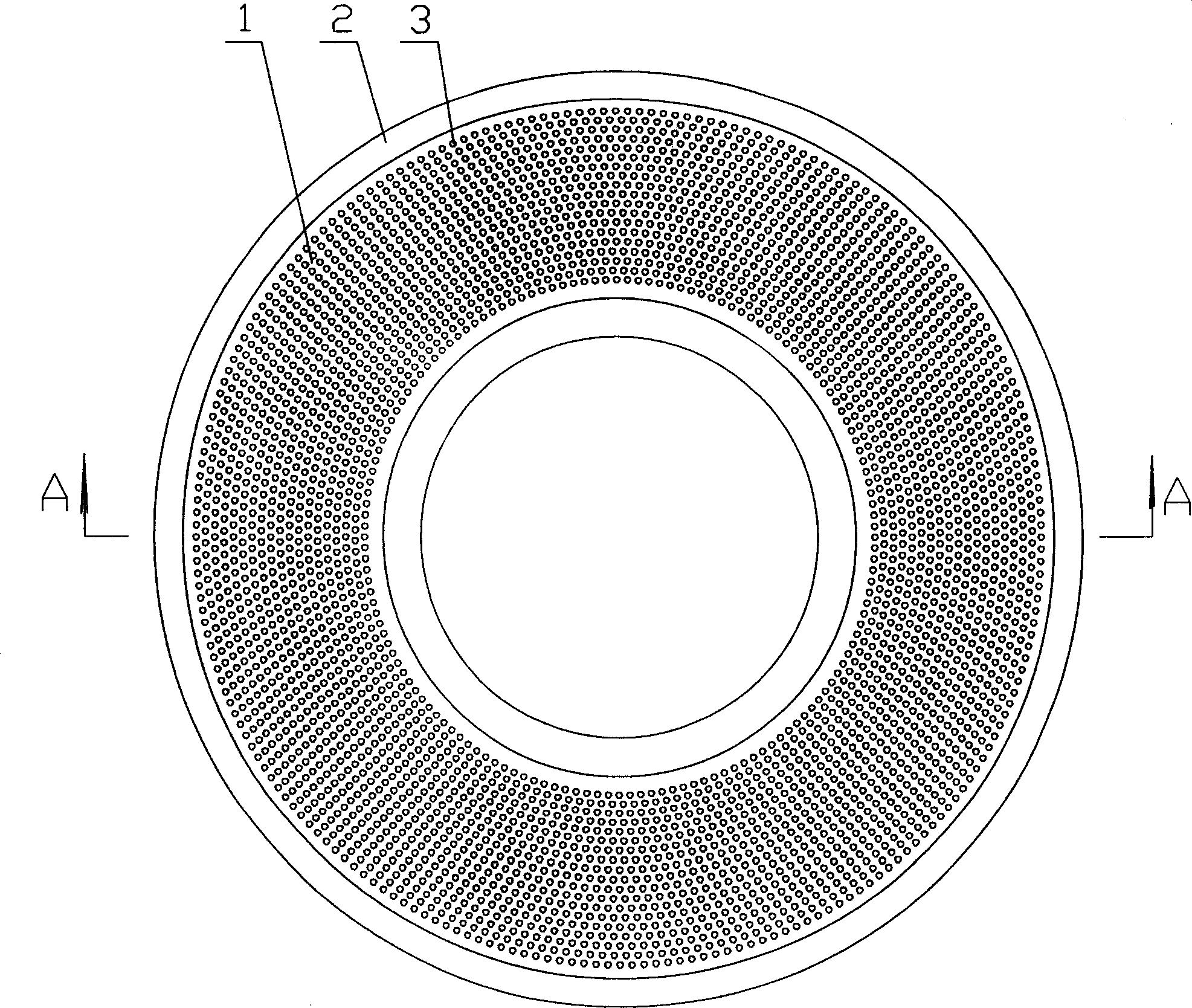

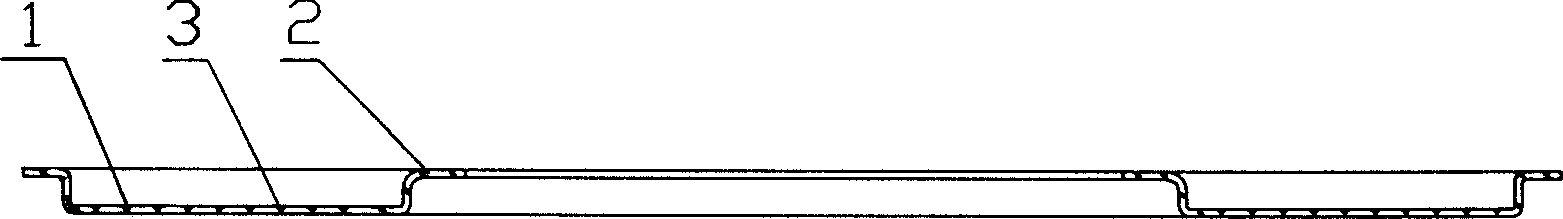

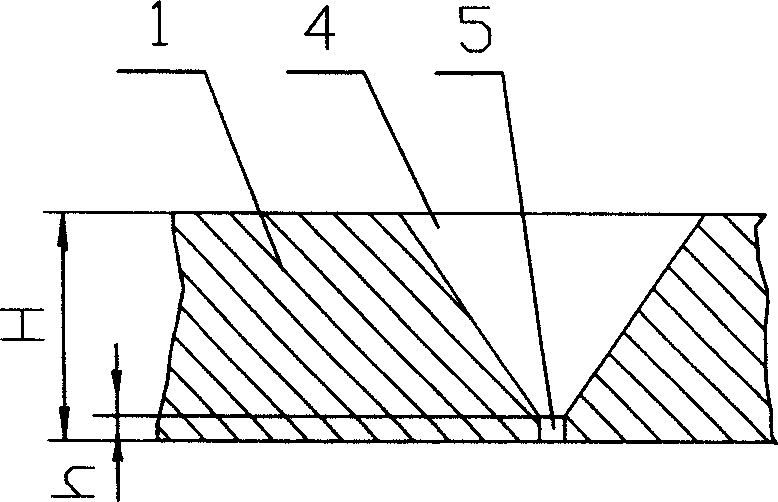

Method for making acrylic fibre by fine denier dry method and spinning nozzle

A technology of dry-process acrylic fibers and production methods, which is applied in the directions of dry-spinning, spinneret assemblies, fiber chemical characteristics, etc., can solve the problems that the quality and price cannot compete with foreign products, and achieve good spinnability and improved hand feeling , Good spinning position stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Be the dry-process acrylic fiber of 1.00dtex to be embodiment with production fineness, comprise the following steps:

[0017] a), Spinning and forming: use polyacrylonitrile dry powder (PAN) as raw material, use dimethylformamide (DMF) as solvent, prepare a polymer stock solution with a concentration of 33 ± 1%, and heat it from the spray Single filaments are extruded from the high-density holes on the wire board. The inner temperature of the heater is controlled at 135±1°C, the outer temperature is controlled at 123±1°C, and the tunnel temperature is 330±10°C from top to bottom. Body temperature is 240±10°C, upper tunnel temperature is 210±10°C, upper tunnel lower temperature is 180±10°C, nitrogen temperature is 370±10°C, nitrogen pressure is 3-4kpa, tunnel productivity is 42±1kg / h, and spray the tow with a cold DMF-containing dilute solvent at the spraying place to obtain primary fibers.

[0018] b) Washing with water and drawing: control the temperature of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com