Heteroepitaxy method for GaN semiconductor material

A heterogeneous epitaxy and semiconductor technology, applied in the field of microelectronics, can solve the problems of high cost, pollution in the etching process, long process cycle, etc., and achieve extended service life, simple template deposition and etching process, and increased storage capacity. The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The substrate SiC (111) is selected as the growth substrate, and the GaN density film is prepared according to the following process:

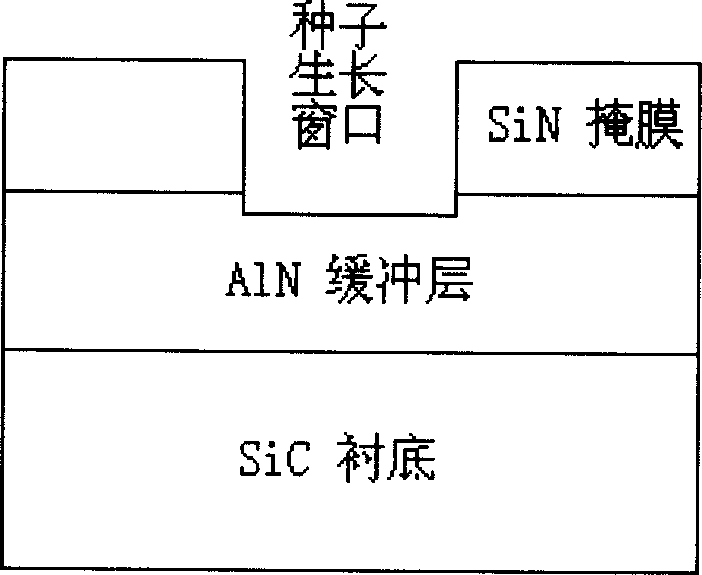

[0036] a. Template preparation

[0037] SiC (111) wafers with a diameter of 1 inch were ultrasonically cleaned in buffer HF for 1 min before growth; rinsed with deionized water and dried, placed in the reaction chamber, and introduced SiH at a suitable high temperature 4 、H 2 mixture, where SiH 4 Accounting for 5%, a 6H-SiC(111) transition film with a thickness of about 1 μm is deposited on the SiC(111) substrate. Next, an AlN buffer layer with a thickness of about 100nm and a SiN thin film are deposited sequentially on the transition layer as a mask, and finally a nickel film is deposited.

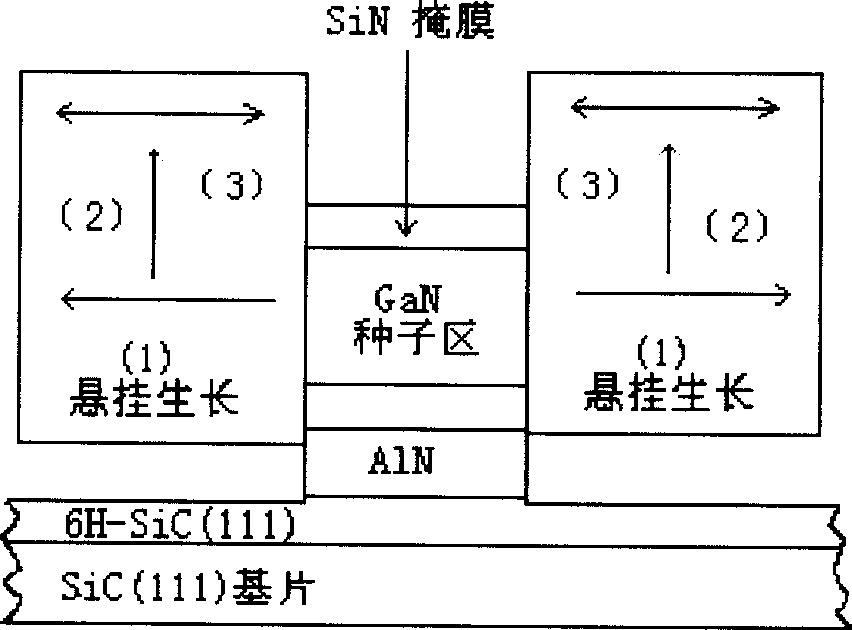

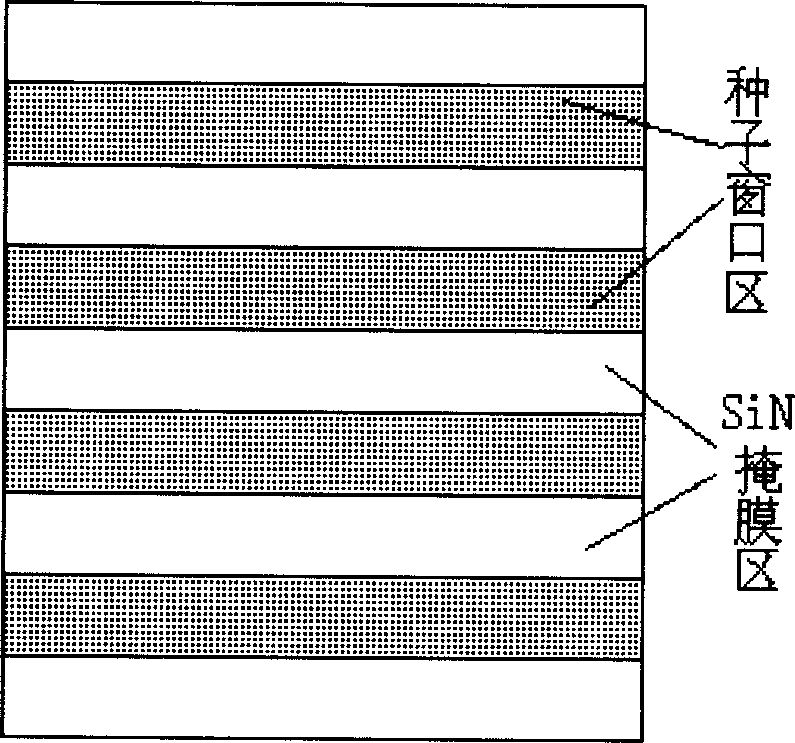

[0038] Using standard photolithography techniques, the reactive sputtering method follows image 3 The bar spacer template flat pattern shown or Figure 4 Part of the nickel film is removed from the planar pattern of the regular hexagonal arra...

Embodiment 2

[0047] The choice of growth substrate sapphire (Al 2 o 3 ) and single crystal silicon, the process of preparing a low defect density GaN thin film is basically the same as that of Example 1.

[0048] The main difference is that in the preparation of the template, before depositing a 6H-SiC(111) transition film with a thickness of about 1 μm, the sapphire Al 2 o 3 A layer of amorphous SiC is deposited on the (111) polished surface of single crystal silicon. The deposition of amorphous SiC is characterized by low substrate temperature and high concentration of precursor gas, and the deposition thickness is about 100nm. Subsequent processes basically follow the steps and parameters of Example 1 to complete the preparation of high-quality thin films.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com