Engineering bacteria for producing 5-amino acetyl propionic acid and its constructing method

A technology of aminolevulinic acid and its construction method, applied in the field of engineering bacteria producing 5-aminolevulinic acid and its construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

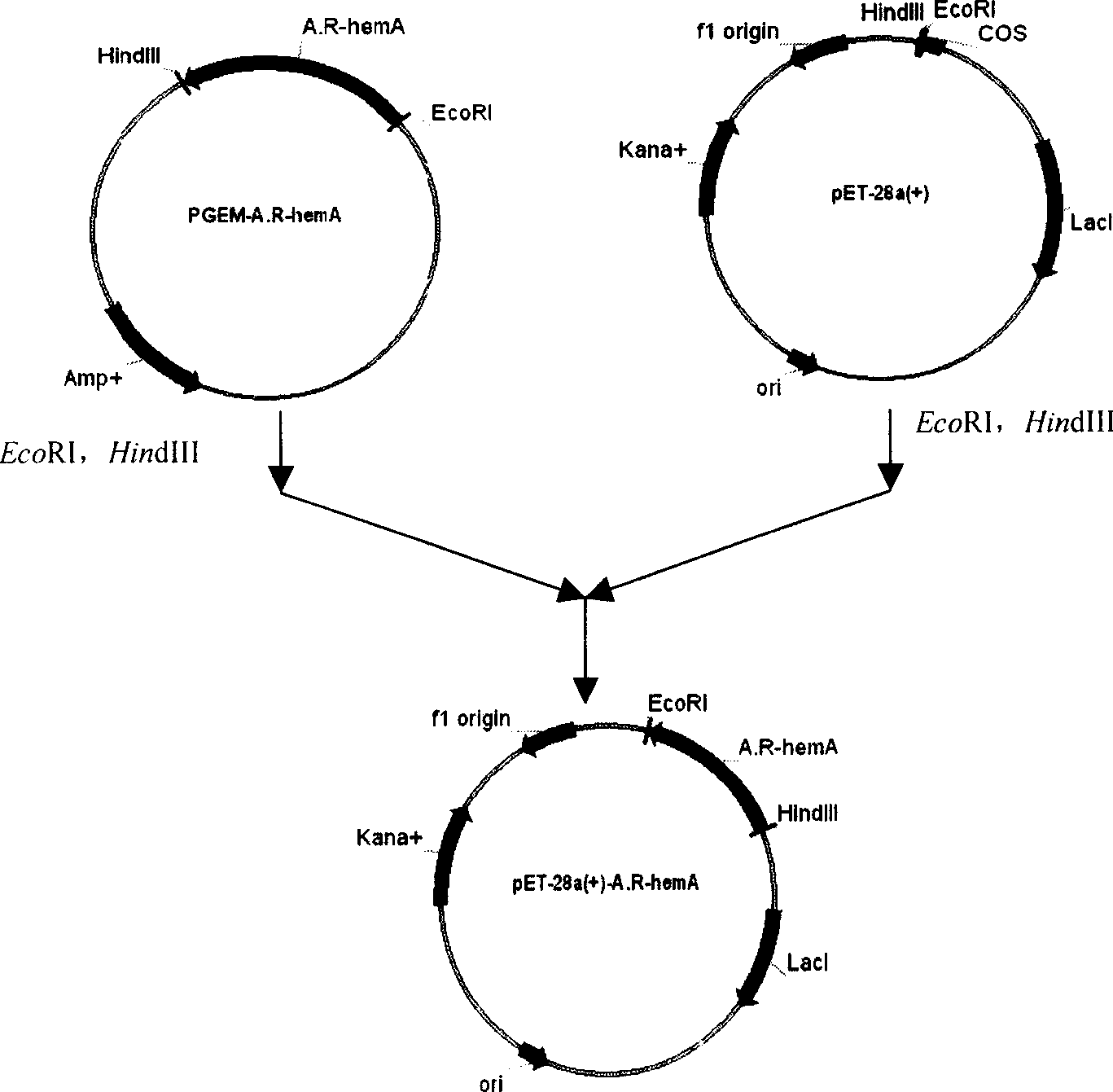

Method used

Image

Examples

Embodiment 1

[0020] The construction method of the engineering bacteria producing 5-aminolevulinic acid of the present invention comprises the following steps:

[0021] 1. Extraction of Genomic DNA from Agrobacterium Radiatus

[0022] 1) Place the overnight cultured bacterial solution in a 1.5ml centrifuge tube, centrifuge at 13,000×g for 1 min and remove the supernatant;

[0023] 2) After dissolving in 475 μl TE buffer, add lysozyme to a final concentration of 100 μg / ml, and incubate at 37°C for 20 minutes;

[0024] 3) Add 10% (w / v) sodium dodecyl sulfonate (SDS) solution to a final concentration of 2% (w / v), and at the same time add 20 mg / ml proteinase K to a final concentration of 100 μg / ml, mix well, Insulate at 37°C for 1 hour;

[0025] 4) Add 1 / 5 volume of 5mol / L NaCl and mix well, then add 1 / 5 volume of 2× cetyltrimethylammonium bromide (CTAB), and keep warm at 65°C for 30 minutes;

[0026] 5) Add an equal volume of a mixture of phenol, chloroform and isoamyl alcohol, the volume ...

Embodiment 2

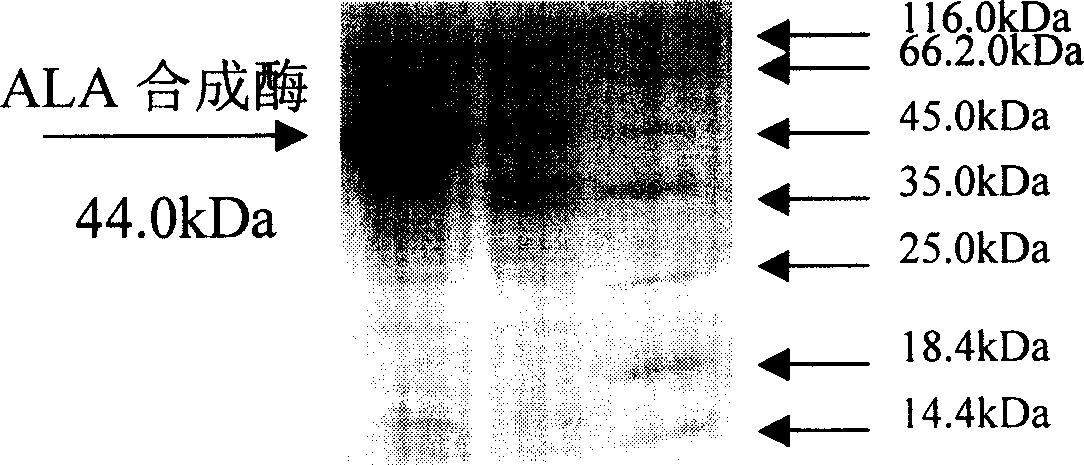

[0047] Expression of 5-aminolevulinic acid synthase under the action of inducer isopropyl-β-D-thiogalactoside (IPTG)

[0048] 1) Cultivate the engineering bacteria BL21(DE3)pET28a-A.R-hemA of the present invention in a 250ml shake flask containing 50ml of LB medium, first culture at 37°C and 200rpm for 1.5h; then cool down to 28°C, and use 4μl Induced by 1mol / L IPTG, after continuing to culture for 4h, take 30ml of the bacterial liquid and centrifuge at 8000×g for 10min to remove the supernatant;

[0049] 2) Resuspend in 3ml 50mmol / L Tris·Cl (pH7.5), ultrasonically break the cells, the conditions are 400w for 5min, 5min rest, repeat 30 times, 13,000×g centrifugation for 10min;

[0050] 3) The supernatant was subjected to 10% SDS-polyacrylamide gel electrophoresis, the electrophoresis conditions were 200v, 500mA, and the time was 1h10min;

[0051] 4) According to the electrophoresis results, there is soluble protein expression accounting for 23.7% of the total protein amount a...

Embodiment 3

[0053] Determination of specific activity of 5-aminolevulinic acid synthase

[0054] 1) 500μl containing 50mmol / L Tris-HCl (pH7.5), 20mmol / L MgCl 2 , 0.1mol / L glycine, 0.1mmol / L pyridoxal phosphate, 0.2mmol / L succinic acid coenzyme A and the mixed solution of the cell extract after cell destruction, react at 37°C for 10min;

[0055] 2) Mix 300 μl of the above reaction solution with 150 μl of 10% trichloroacetic acid in a 1.5 mL centrifuge tube, and centrifuge at 13,000×g for 5 min;

[0056] 3) Mix 300 μl supernatant with 400 μl 1mol / L acetate buffer (pH 4.6) and 35 μl acetylacetone, and bathe in boiling water for 15 minutes;

[0057] 4) After it cools down, add 700 μl of newly prepared Ehrlich reagent (in a 50ml graduated cylinder, add 30ml of glacial acetic acid, 1g of p-dimethylaminobenzaldehyde, 5ml of 70% perchloric acid, 5ml of water, after dissolving Dilute to 50ml with glacial acetic acid), measure its absorbance value at 554nm place after reacting for 5min, the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com