Face light source module based on LED

A light-emitting diode and surface light source technology, which is applied in the field of indoor lighting lamps and surface light source modules, can solve the problems that it is difficult to break through the upper limit of the principle light guide efficiency, the upper limit of the light guide efficiency, and cannot reach a higher level, so as to achieve a good home decoration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

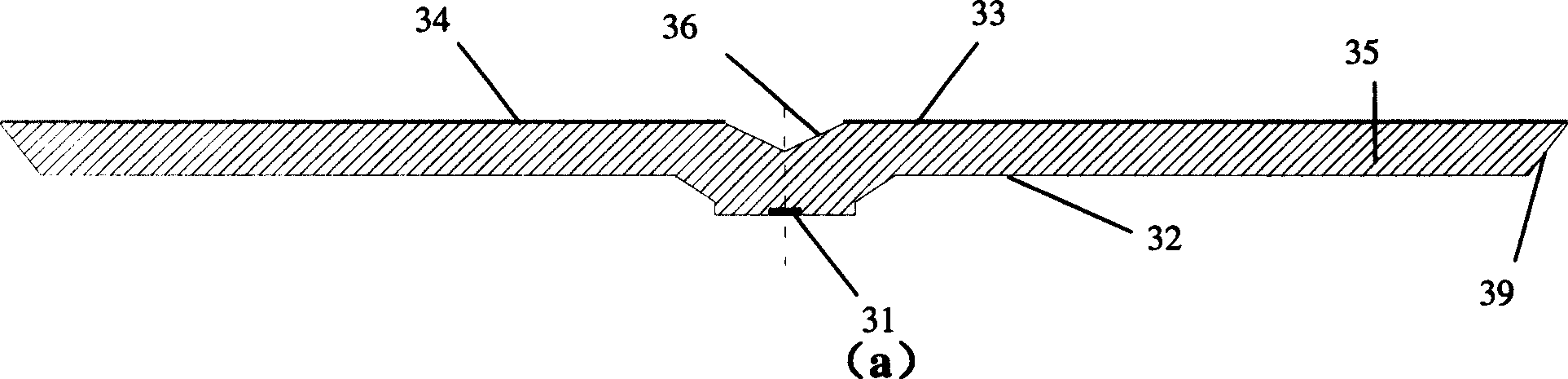

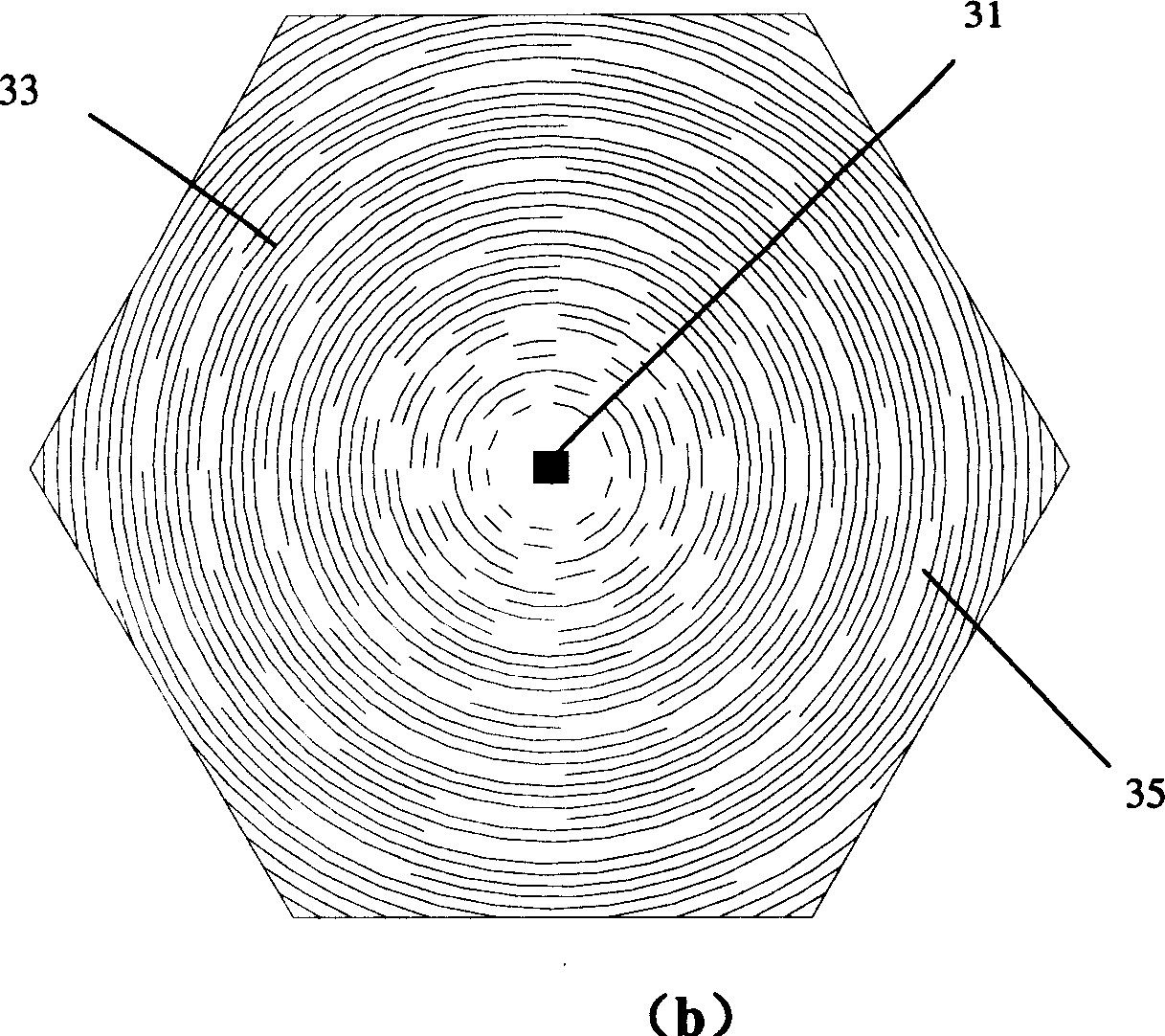

[0050] Example 1 is as Figure 4 The surface light source module based on light emitting diodes 31 is shown. In embodiment 1, a primary light source is used, the core part of which is a single LED chip, and the light source is located at the geometric center of the surface light source module. The projection of the light emission guide structure 33 in the first embodiment on the main emission surface 34 is a circular arc centered on the projection point of the primary light source on the main emission surface 34 .

[0051] The critical condition for total reflection of light at the PMMA-air interface is:

[0052]

[0053] When the incident angle of light θ i satisfy

[0054] θ i ≥θ ic When , the light is now totally reflected at the PMMA-air interface, and this condition is referred to as the total reflection condition hereinafter.

[0055] Such as Figure 4 As shown, the light emitted by the primary light source is divided into four parts accor...

Embodiment 2

[0060] The surface light source module based on light-emitting diodes in Embodiment 2 is different from Embodiment 1 in that the longitudinal section shape of the light emitting guide structure 33 is different. Here, the different parts will be mainly explained, and the repeated description of the same parts will be omitted.

[0061] The longitudinal section shape and local light paths of the light exit guide structure 33 of Embodiment 2 are as follows: Figure 5 shown. It can be seen that the light partially incident on the light exit guiding structure 61 does not satisfy the total reflection condition at the interface and exits from the main exit surface 34 . Similarly, because there is almost no useless outgoing light emitted from the lower surface 32 of the light guide plate, the total light guide efficiency of the light guide plate 35 can reach a level similar to that of Embodiment 1, but the distribution of light emission angles is slightly different from Embodiment 1. ...

Embodiment 3

[0062] The surface light source module based on the light emitting diodes 31 of the third embodiment is different from the first embodiment in that the specific projection shape of the light emitting guide structure 33 on the main emitting surface is different. The different parts are explained here emphatically, and repeated explanations for the same parts are omitted.

[0063] The top view of the surface light source module of Embodiment 3 is as follows Figure 6shown. The projection of the light emission guide structure 71 on the main emission surface 34 is a straight line segment, but still satisfies the condition of an approximate circular arc with the projection point of the primary point light source on the main emission surface 34 as the approximate center of the circle, that is, from the primary point light source 31 The included angle (acute angle) between the connection line 72 to any point A on the light emitting guide structure 33 and the tangent line 73 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com