Molecular cngram resin and prepartion method, and application for separating and purifying protein

A molecular imprinting and resin technology, applied in the field of protein separation and purification, can solve the problem of difficult to remove template imprinting effect, and achieve the effect of avoiding damage, strong visibility and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

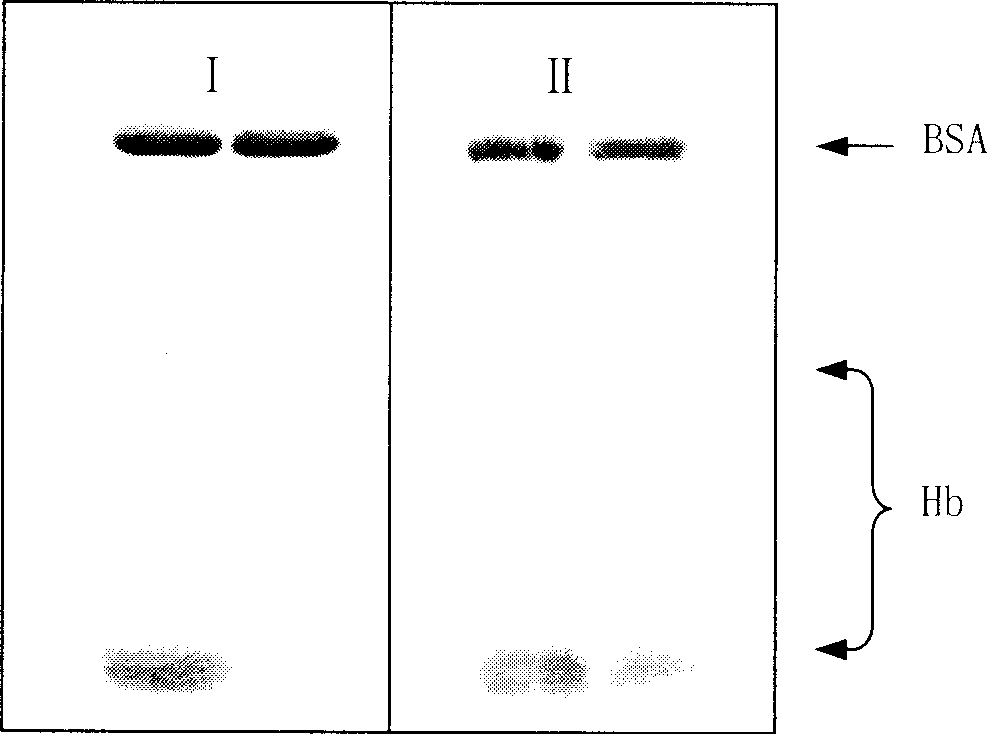

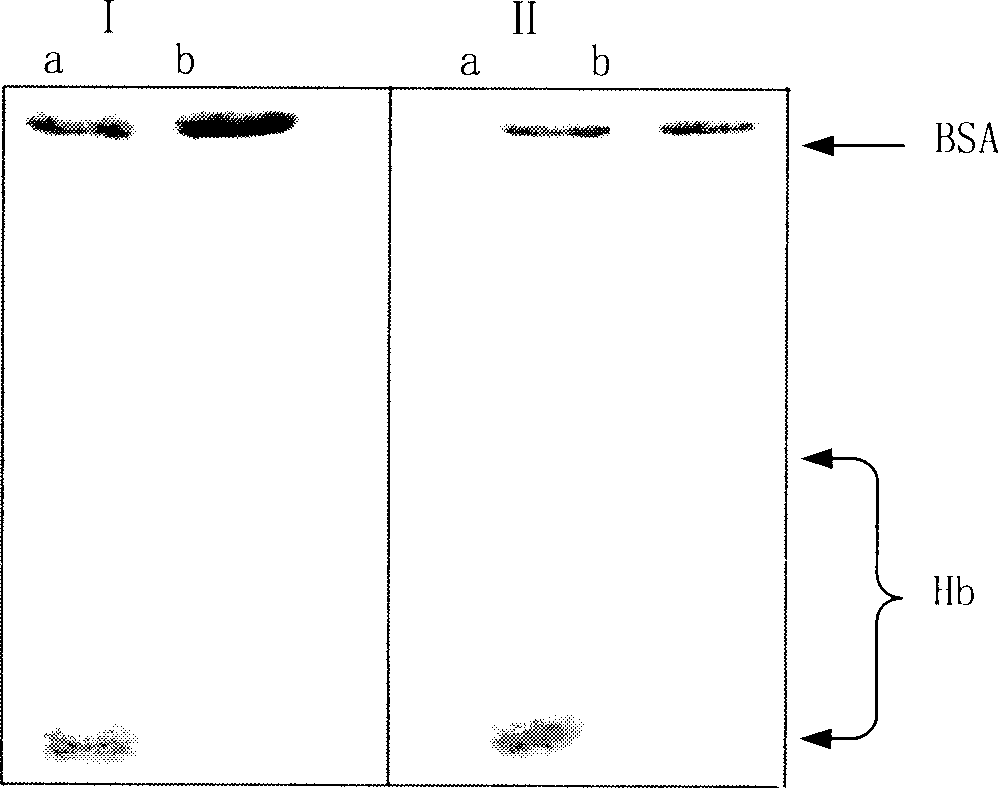

Image

Examples

Embodiment 1

[0028] Add 53mL of vinyl acetate, 490mL of methanol, and 0.5g of azobisisobutyronitrile into the reaction flask, pass nitrogen and remove oxygen, and react at 70°C for 4h. Add 4.3 g of 40% sodium hydroxide solution to the methanol solution of 10% polyvinyl acetate prepared above, and alcoholyze at 30° C. for 3 h. After centrifugation, vacuum-dry at room temperature for 24 hours to obtain polyvinyl alcohol (PVA).

[0029] Dissolve 2g of polyvinyl alcohol in 18mL of water, add 2mL of dimethylformamide, and pass N at 40°C 2 After 50 minutes, 0.9 mL of nitric acid solution of ammonium cerium nitrate was added, after 15 minutes, 1.94 g of acrylamide was added, after 15 minutes, 1.43 g of 4-vinylpyridine was added, and the reaction was carried out under nitrogen protection at 45°C for 10 hours. Precipitate, separate, and dry in a vacuum oven for 24 hours to obtain PVAVP, a copolymer of polyvinyl alcohol grafted with acrylamide and 4-vinylpyridine.

[0030] Dissolve 1 g of PVAVP in...

Embodiment 2

[0068] Add 16 mL of vinyl acetate, 264 mL of methanol, and 0.15 g of azobisisobutyronitrile into the reaction flask, pass nitrogen and remove oxygen, and react at 65°C for 6 hours. Add 5.73 g of 40% sodium hydroxide solution to the methanol solution of 13% polyvinyl acetate prepared above, and alcoholyze at 35° C. for 3 h. After centrifugation, vacuum-dry at room temperature for 24 hours to obtain polyvinyl alcohol (PVA).

[0069] Polyvinyl alcohol (PVA) 1g, dissolved in 20ml of water, 35 ° C N 2 After 50 minutes, 0.45 mL of nitric acid solution of ammonium cerium nitrate was added, after 15 minutes, 1.04 g of acrylamide was added, after 15 minutes, 0.843 g of 4-vinylpyridine was added, and the reaction was carried out under nitrogen protection at 40°C for 24 hours. Precipitate, separate, and dry in a vacuum oven for 24 hours to obtain PVAVP, a copolymer of polyvinyl alcohol grafted with acrylamide and 4-vinylpyridine.

[0070] Dissolve 0.8g of PVAVP in 15mL of dimethyl sulf...

Embodiment 3

[0080] Add 53mL of vinyl acetate, 574mL of methanol, and 0.65g of azobisisobutyronitrile into the reaction flask, pass nitrogen and remove oxygen, and react at 60°C for 10h. Add 4.78 g of 40% sodium hydroxide solution to the 8% methanol solution of polyvinyl acetate prepared above, and alcoholyze at 30° C. for 2 h. After centrifugation, vacuum-dry at room temperature for 24 hours to obtain polyvinyl alcohol (PVA).

[0081] Polyvinyl alcohol (PVA) 4g, dissolved in 20ml of water, add 5mL of dimethylformamide, 35 ℃ pass N 2 After 50 minutes, 1.10 mL of nitric acid solution of ammonium cerium nitrate was added, after 15 minutes, 3.92 g of acrylamide was added, after 15 minutes, 2.89 g of 4-vinylpyridine was added, and the reaction was carried out under nitrogen protection at 35°C for 36 hours. Precipitate, separate, and dry in a vacuum oven for 24 hours to obtain PVAVP, a copolymer of polyvinyl alcohol grafted with acrylamide and 4-vinylpyridine.

[0082] Dissolve 2g of PVAVP in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com