Polyformaldehyde resin made twisting yarn

A polyoxymethylene resin and twisted yarn technology, applied in the twisted yarn field, can solve the problems of lack of stability such as long-term heat resistance stability, inability to obtain durability, poor productivity, etc., and achieve high strength, high elasticity, Excellent high temperature rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

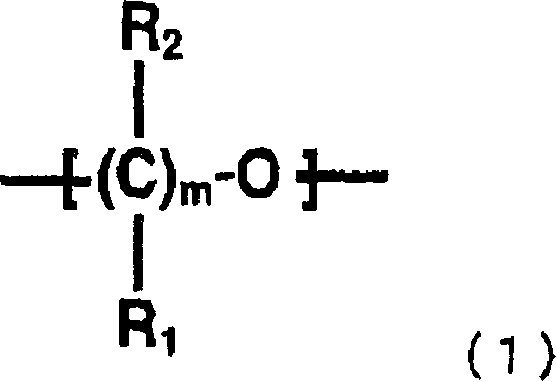

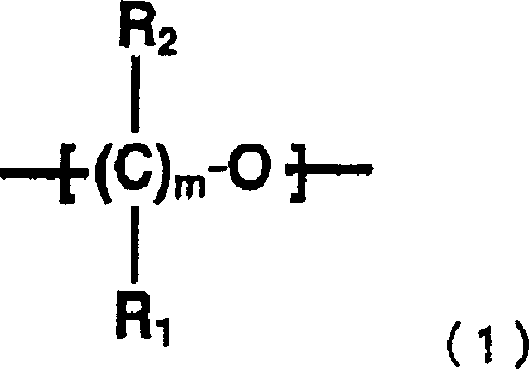

Method used

Image

Examples

Embodiment 1-8

[0026] A continuous mixing reactor consisting of a jacket with a circulating hot (cold) medium on the outside, a cylinder whose cross-section is the overlapping shape of two circles, and a rotating shaft with paddles is used, and two rotating shafts with paddles are used The shafts are rotated at 150rpm, while liquid trioxane, cyclic ether or cyclic formal (1,3-dioxolane, 1,4-butanediol formal, diethylene glycol formal, etc. formaldehyde), further supply molecular weight modifier methylal continuously in polymerizer, supply 50ppm catalyst boron trifluoride (relative to monomer total amount) simultaneously, carry out bulk polymerization, prepare the polymkeric substance of comonomer amount shown in table 1 . The reaction product discharged from the polymerizer was quickly introduced into a pulverizer, and a 60° C. aqueous solution containing 0.05% by weight of triethylamine was added to deactivate the catalyst. After further separation, washing and drying, the crude polyoxymet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com