Flowing light discharge plasma oxygenized sulfite

A technology for oxidizing sulfite and plasma, applied in the direction of sulfate preparation, etc., can solve the problems of large reactor and long reaction time, and achieve the effects of short processing time, small volume and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

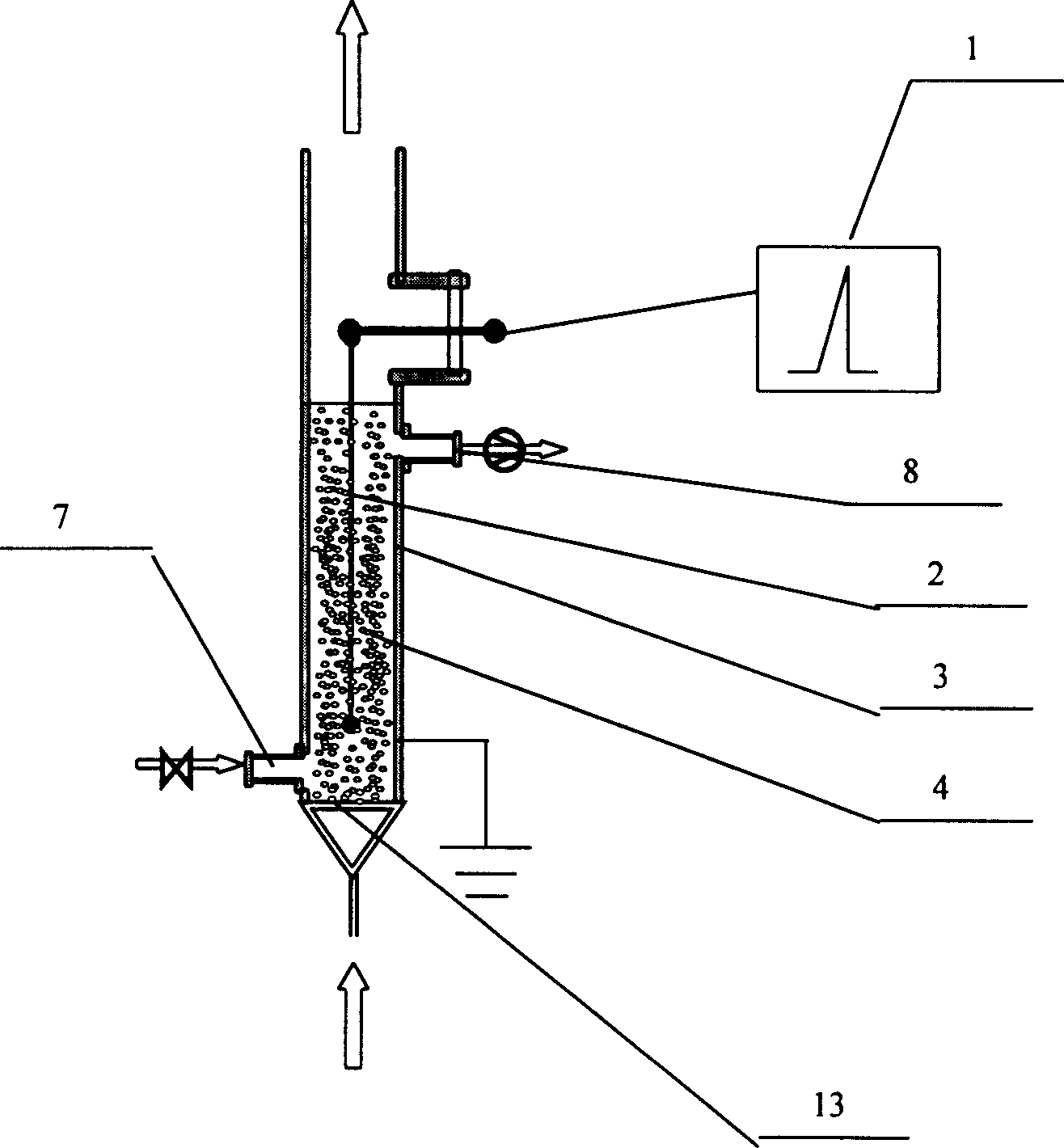

[0031] Such as figure 2 As shown, the reactor is a vertical cylindrical structure, and the streamer discharge is generated between the discharge electrode 2 and the ground electrode 3 by means of a high-voltage narrow pulse power supply 1. The injection power is 100 watts, and the reactor is filled, and the oxygen-containing gas is air. It is blown in from the bottom of the reactor through the sieve plate 13, the opening ratio of the sieve plate is 47%, the height of the hydrostatic layer is 10mm, and the sulfurous acid to be treated with a volume of 10 liters and a concentration of 2 moles injected into the reactor by 7 Salt solution, in plasma reaction zone 4, forms bubble, causes discharge oxidation reaction, and the sulfate solution after treatment is discharged by outlet 8, and tail gas is discharged from reactor top, and oxidation rate reaches 95%, and energy consumption is 15 watt hours / Moore.

[0032] Compared with the conventional chemical technology, the practical...

specific Embodiment approach 3

[0033] Such as image 3 As shown, the streamer discharge takes place between the discharge electrode 2 and the ground electrode 3 by means of a high-voltage power supply 1, and fills the reactor. The carrier 15 is composed of a porous ceramic with a specific surface area of 8 square centimeters per cubic centimeter. The sulfite solution 7 to be treated is leaked into the carrier through the injection device 5 in the groove on the top of the reactor, and flows through the surface of the porous ceramic. It is 10 liters / hour, and the oxidation process in the carrier liquid film is initiated by streamer discharge, and the discharge power is 100 watts. The treated normal salt solution is discharged from 8, the oxidation rate reaches 98%, and the energy consumption is 17 Wh / mol.

[0034] Compared with the conventional chemical technology, the practical industrial technology of streamer discharge plasma oxidation of sulfite provided by the present invention has the following benef...

specific Embodiment approach 4

[0035] Such as Figure 4 As shown, the flue gas after heat exchange 14a is 110 degrees Celsius, and enters the top of the gas-liquid-solid three-phase vertical streamer discharge reactor 3a. reaction, oxidize the residual sulfite in the resulting liquid to sulfate, discharge the resulting dry powder from 3a to the tank 12, the flue gas is cooled and humidified through 3a, and enters the thermochemical reactor 9 from the bottom side of the device for use in The circulating ammonia-containing liquid in the liquid storage tank 10 and the liquid storage adjustment tank 11 is repeatedly leached, and ammonia water is injected into the sub-stoichiometric amount in 11, so that the solute of the generated liquid is mainly ammonium bisulfite. An appropriate amount of the generated liquid is injected into the normal temperature vertical streamer discharge reactor 3b to continue to oxidize the nitrite, and process the gas entering 3b from 9, because the gas in 9 and 3 is all treated with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com