Method of preparing LiGaO2/beta-Ga2O3 composite backing material

A composite substrate, -ga2o3 technology, used in semiconductor/solid-state device manufacturing, semiconductor lasers, lasers, etc., can solve problems such as waste of raw materials, difficulty in crystal growth, and high dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

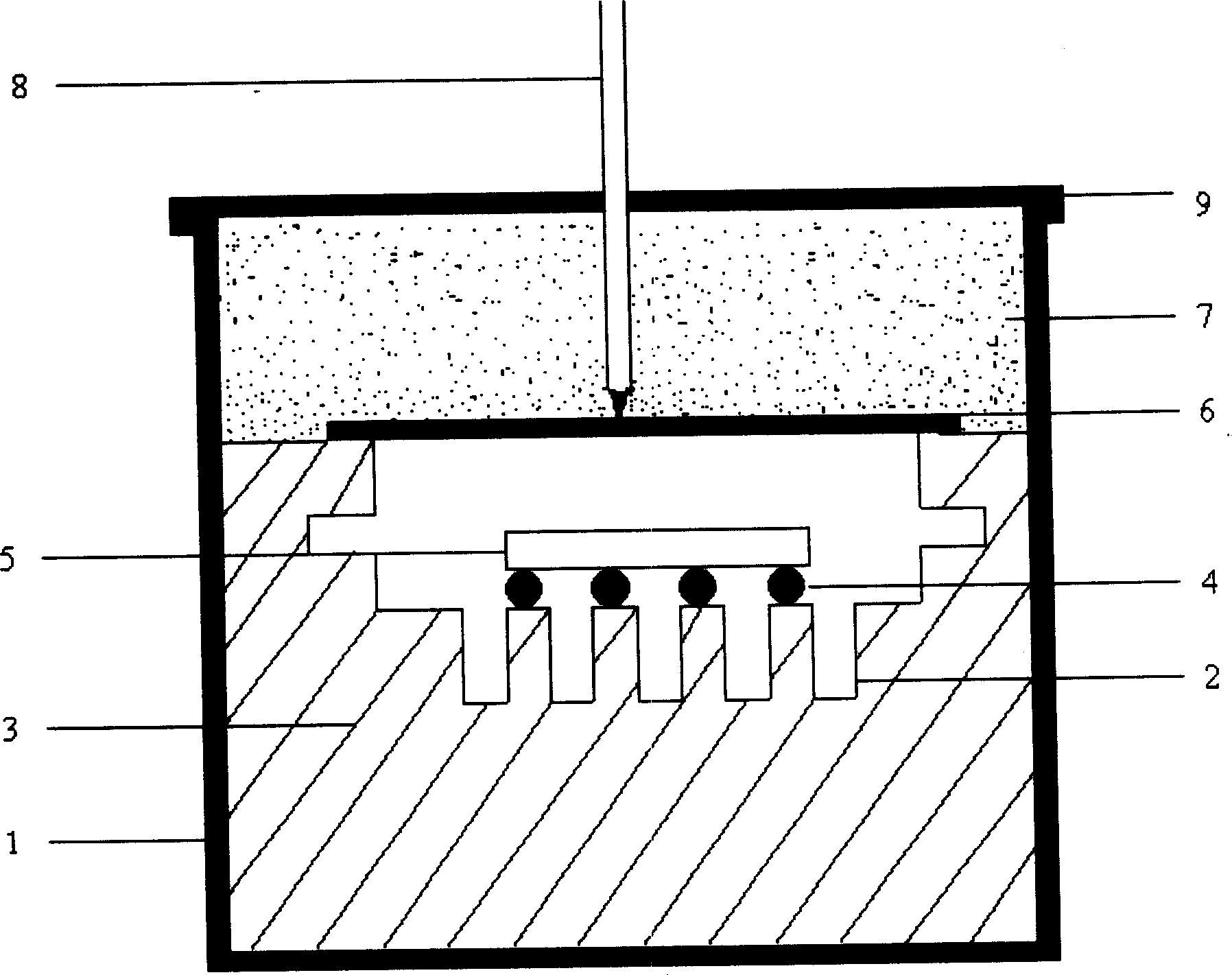

[0016] The Vapor Transport Equilibrium (VTE) technique used in the present invention prepares composite substrate material LiGaO 2 / β-Ga 2 o 3 The schematic diagram of the experimental setup is shown in figure 1 , in the platinum crucible 1, a certain ratio of LiGaO with pores 2 is placed 2 and Li 2 O mixed material block 3, the upper part of material block 3 is platinum wire 4, double-sided polished or single-sided polished β-Ga 2 o 3 The wafer 5 is placed on the platinum wire 4, and the upper part of the material block 3 has a platinum sheet 6 and LiGaO 2 and Li 2 O mixed powder 7 covered, thermocouple 8 inserted in the powder 7, crucible 1 top with platinum cover 9 airtight.

[0017] Vapor Transport Equilibrium (VTE) technology is a mass transport process, so there should be enough Li in the crucible 2 O supply, secondly, the equilibrium of the gas phase is dependent on the Li 2 A steady stream of O from LiAlO 2 and Li 2 O is maintained by volatilization in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com