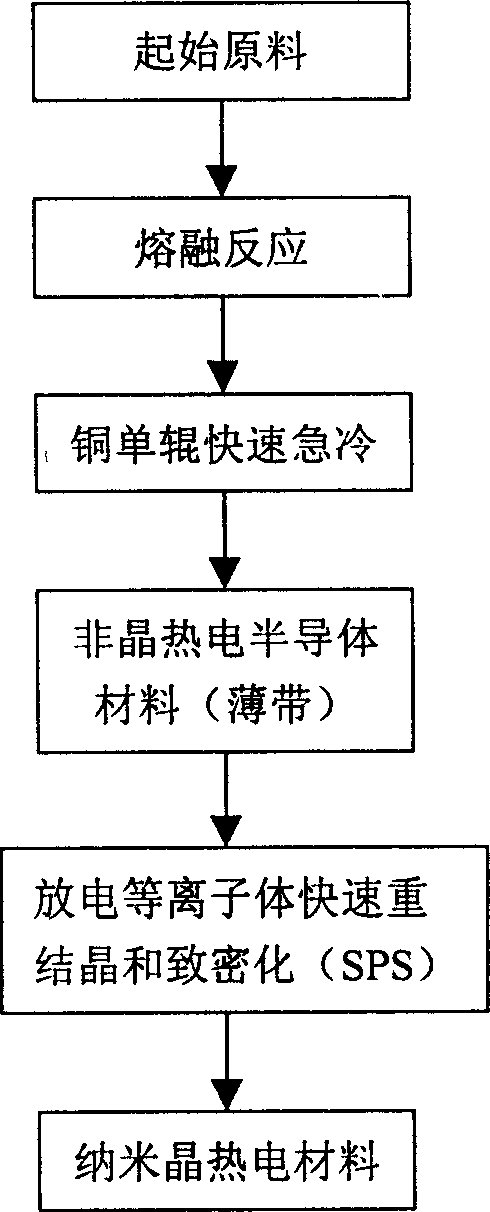

Amorphous crystallization preparation method for nano crystal thermoelectric semiconductor material

A thermoelectric semiconductor and nanocrystalline technology, applied in the field of new energy materials, can solve the problems of easy introduction of other impurities, uneven grain size, difficulty in obtaining high-purity thermoelectric semiconductor materials, etc. The effect of easy large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Bulk CoSb 3 Preparation of Nanocrystalline Thermoelectric Semiconductor Materials

[0022] Using cobalt powder and antimony powder as raw materials, melt reaction at 1100°C to obtain uniform CoSb 3 Melt, using copper single copper roll quenching technology, with 10 5 ℃ / sec cooling rate to prepare CoSb 3 Amorphous alloy strips, the obtained strips have a width of about 2-3 mm, a thickness of about 25 μm, a length of several meters, and a smooth surface.

[0023] Grind strips weighing about 5g into powder, then put them into a φ10mm graphite mold for compaction, and then move them together with the mold into the discharge plasma rapid recrystallization and densification sintering (SPS) equipment. The vacuum degree in the furnace is 10 -3 Pa, the temperature was raised to 600°C for recrystallization, and the pressure of 30MPa was used for densification. The recrystallization and densification time was 7 minutes. After cooling, take out the mold and get a blo...

Embodiment 2

[0024] Example 2: Bulk Ba filled nano-skutterudite compound Ba y co 4 Sb 12 Preparation of Thermoelectric Semiconductor Materials

[0025] Using bulk barium, cobalt powder and antimony powder as raw materials, melt reaction at 1100°C to obtain uniform Ba-filled Ba y co 4 Sb 12 Melt, using copper single copper roll quenching technology, with 10 5 ℃ / sec cooling rate to prepare Ba y co 4 Sb 12 Amorphous alloy strips, the obtained strips have a width of about 2-3 mm, a thickness of about 25 μm, a length of several meters, and a smooth surface.

[0026] Grind strips weighing about 8g into powder, then put them into a φ20mm graphite mold for compaction, and then move them together with the mold into the discharge plasma rapid recrystallization and densification sintering (SPS) equipment. The vacuum degree in the furnace is 10 -3 Pa, the temperature was raised to 600°C for recrystallization, and the pressure of 30MPa was used for densification. The recrystallization and den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com