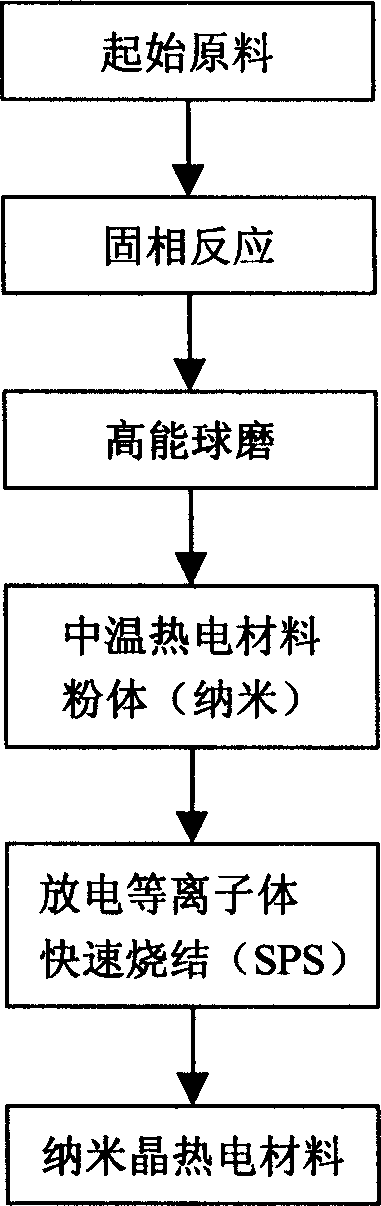

Preparation method for nano skutterudite compound pyro electric material

A thermoelectric material and skutterudite technology, applied in the field of preparation of nanometer skutterudite compound thermoelectric materials, can solve problems such as difficulty in preparing nanocrystalline thermoelectric materials, and achieve simple preparation process, easy large-scale industrial production, and particle distribution. narrow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The invention adopts a tungsten carbide ball mill jar, the ball mill medium is tungsten carbide balls, and the diameters of the balls are 10mm and 5mm respectively. During the experiment, it was found that the ball milling effect was the best when the material-ball ratio was 1:7. Table 1 shows the effect of ball size on the particle size of powder after ball milling. The particle size of the powder obtained by ball milling for 24 hours under different grading ratios with a feed-to-ball ratio of 1:7, a rotational speed of 300r / min, and a ball milling time of 24 hours. The table lists the corresponding relationship between the powder particle size and its percentage. It can be seen that the impact of medium gradation on particle size and distribution range is significant. On the one hand, the mass of large balls is large, and the addition of large balls is beneficial to the minimum particle size of powder particles. When the mass percentage of large balls reaches 20%, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com