Sulfonic acid functional macromolecular/SiO2 composite nano-particles and process for preparing same

A composite nanoparticle and functional technology, which is applied in the field of sulfonic acid functional polymer/SiO2 composite nanoparticle and its preparation, can solve the problems of shedding of the coating layer, difficulty in separation, purification and purification of products, and increase in cost, so as to reduce production Cost, good chemical reactivity, ease of storage and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

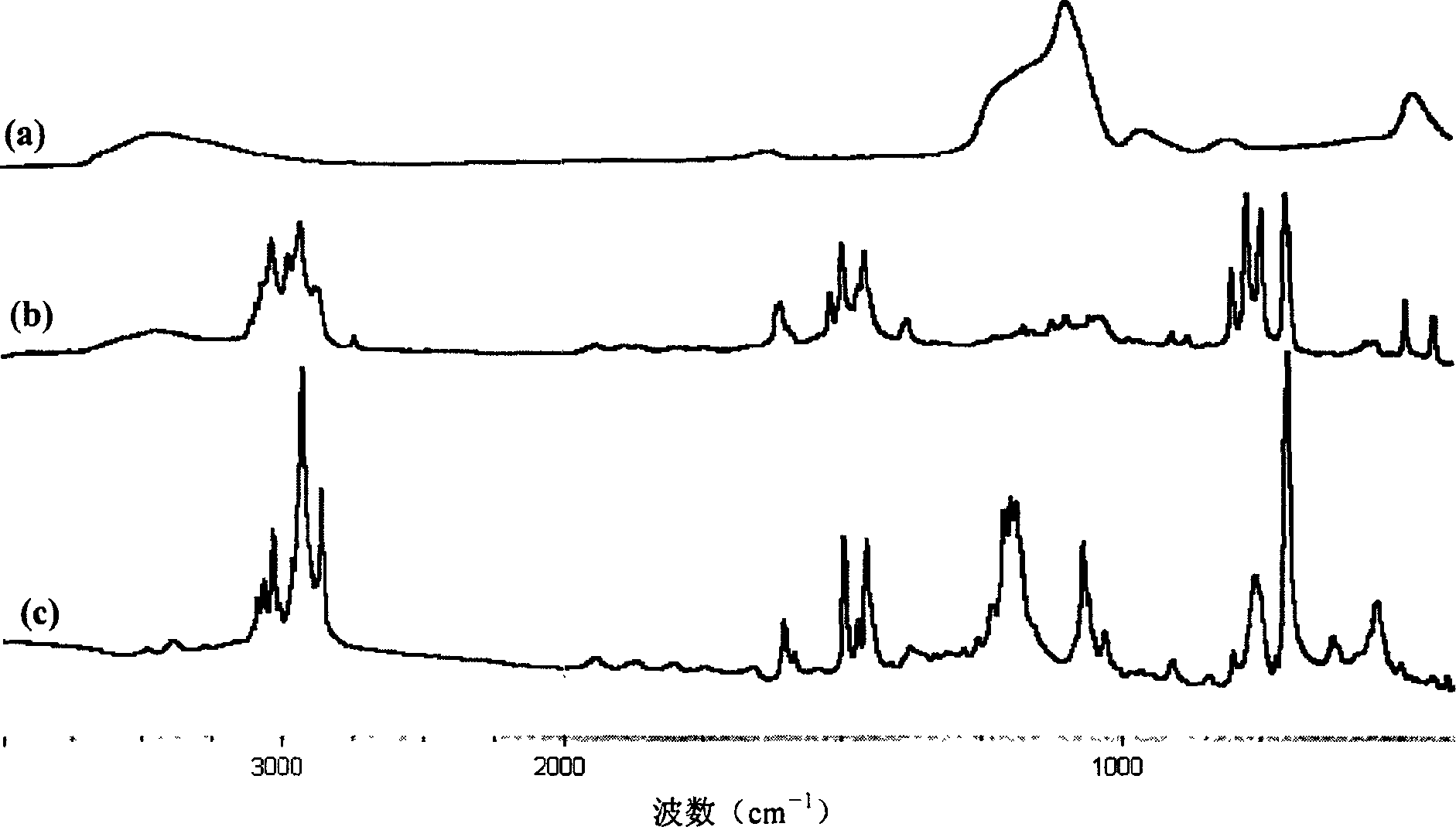

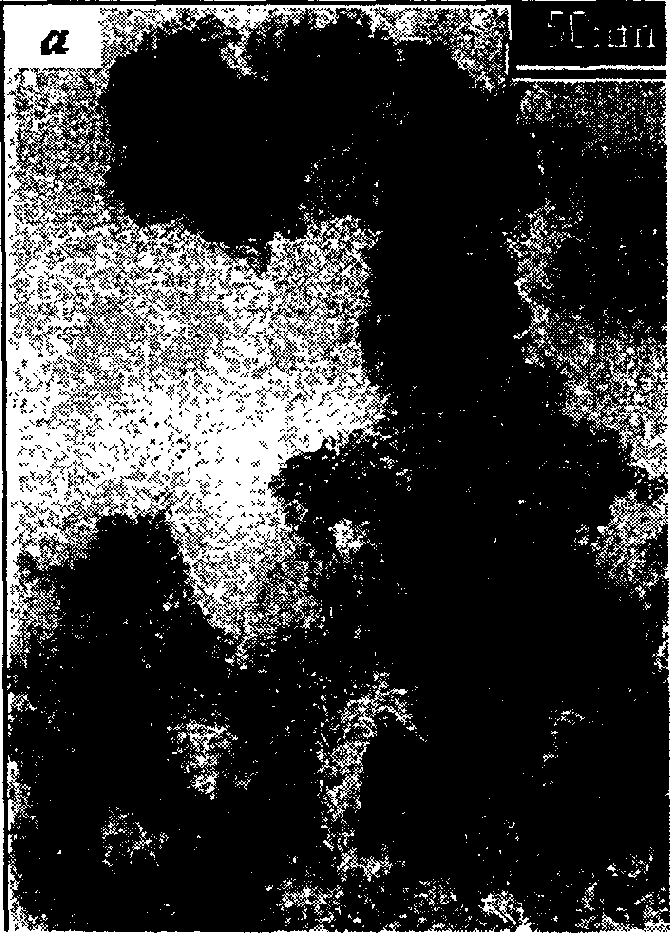

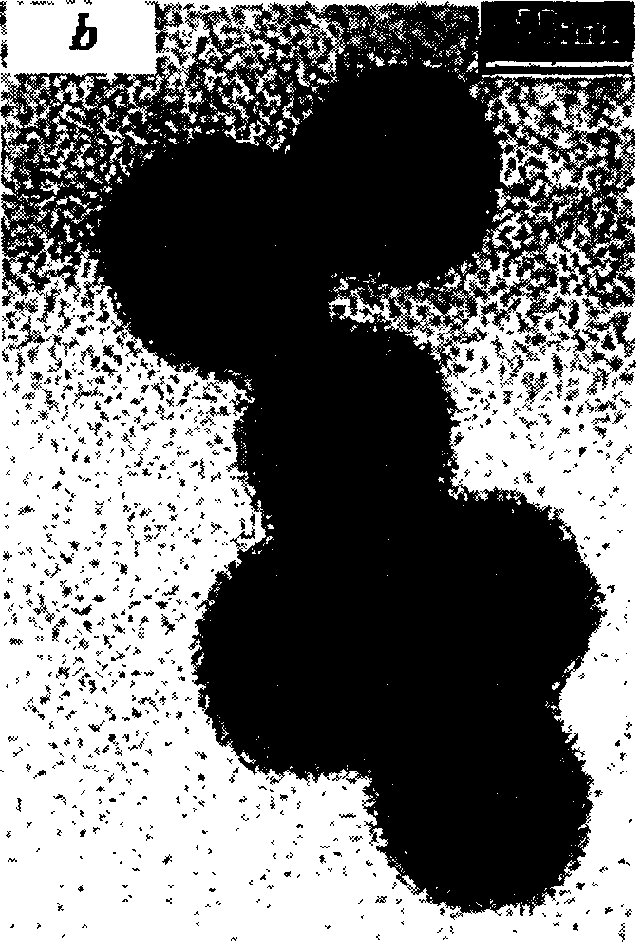

[0046] Example 1: Set the average particle size to 10±5nm and the specific surface area to 640m 2 / g of nano SiO 2 After dry treatment with 5wt% KH-570 silane coupling agent, 4 parts are weighed and added to 100 parts of styrene monomer, stirred and ultrasonically dispersed uniformly. Add 370 parts of deionized water and 7 parts of sodium 1-tetradecenyl sulfonate into a four-necked flask equipped with mechanical stirring, reflux condenser and thermometer. Add monomer and SiO 2 mixture. Then, 80% of the initiator aqueous solution prepared by 0.5 parts of water-soluble initiator ammonium persulfate and 75 parts of deionized water was added, and the temperature was raised to 82° C. for 1.5 hours. The temperature is raised to 90°C, the remaining water-soluble initiator solution is added, the reaction is continued for 0.5 hours, and the material is cooled and discharged. After the discharged part of the emulsion was demulsified, washed, and dried, a white powdery product was obtained. ...

Embodiment 2

[0047] Example 2: Change the styrene in Example 1 to the same amount of butyl acrylate. The reaction was carried out at 60°C for 8 hours. After adding the remaining water-soluble initiator, the reaction was completed for 2 hours. The rest of the formula and steps were the same as those in Example 1. the same. The yield, grafting rate and grafting efficiency of the obtained product are 94.6%, 2723% and 96.7%, respectively, and the particle size distribution is 60-70 nm.

Embodiment 3

[0048] Example 3: Change the styrene in Example 1 to a mixture of isobutadiene and methyl methacrylate (half each) with the same total weight, add 50% of the total initiator at 50°C, and react at 95°C Continue for 0.5 hours, and the rest of the formula and steps are the same as in Example 1. The yield, grafting rate and grafting efficiency of the obtained product are respectively 93.8%, 2579% and 91.6%, and the particle size distribution is 60-70 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com