Dipped barium tungsten cathode based on tungsten irridium alloy and its preparation method

A barium-tungsten cathode and alloy technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of complicated processes, insufficient emission current of the impregnated barium-tungsten cathode, and long life, etc. Good process repeatability and stability, facilitate electron emission, and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

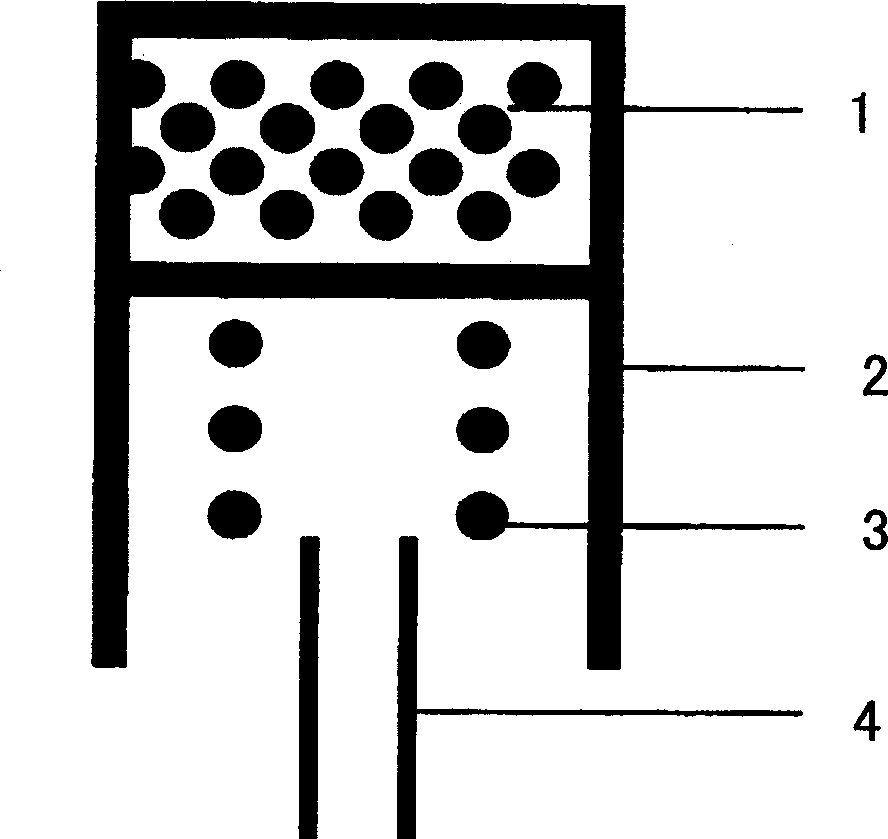

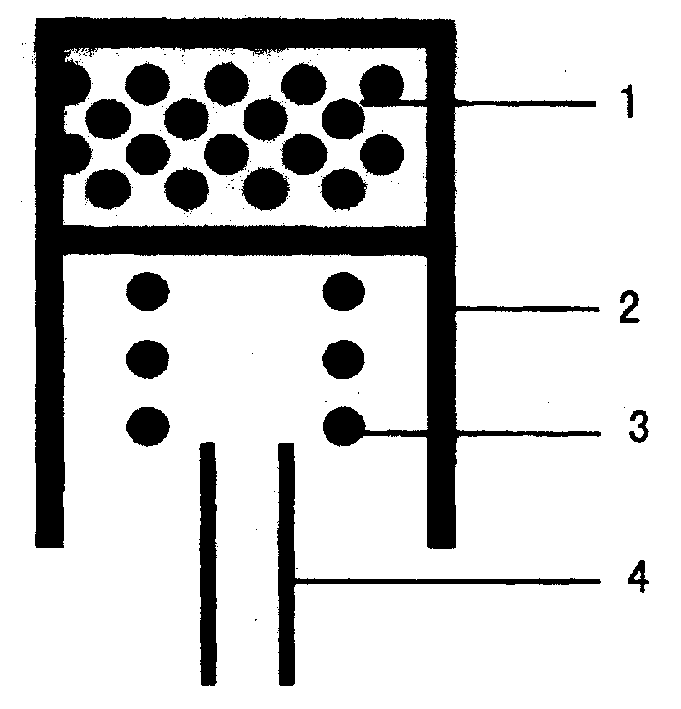

[0021] The impregnated barium tungsten cathode provided by the invention is composed of 10-30% iridium powder and 70-90% tungsten powder in weight ratio, and aluminate is impregnated in the pores.

[0022] The method for preparing the above-mentioned impregnated barium tungsten cathode provided by the present invention is:

[0023] 1) Use micro-particles, high-purity tungsten powder and iridium powder, put the tungsten powder and iridium powder into a hydrogen furnace at 1200 ℃ for annealing to thoroughly purify and enhance their plasticity.

[0024] 2) Take 20% iridium powder and 80% tungsten powder according to the weight ratio, and mix and grind the two materials to ensure uniformity. The mixture was pressed into a flat-topped cathode body using a die containing a cylinder of molybdenum. The flat top cathode body has a diameter of 2-5mm and a thickness of 1-4mm. The flat top cathode body prepared in this example has a diameter of 3.6 mm and a thickness of 2 mm.

[0025] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com