Improved sublimation purification method

A purification method and purification device technology, applied in chemical instruments and methods, sublimation, separation methods, etc., can solve the problems of less collection, loose tissue, and limited quality, and achieve improved heat transfer efficiency, easy pressure control, and heat transfer speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

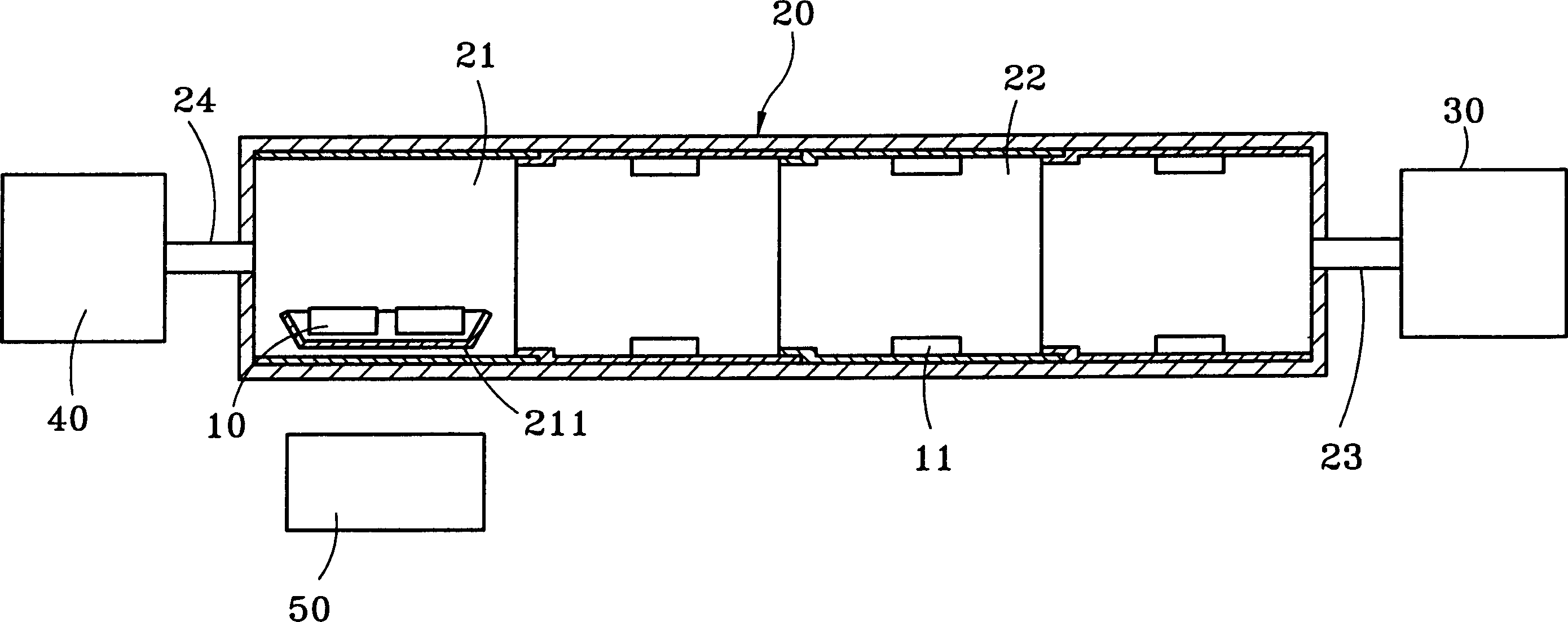

[0010] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

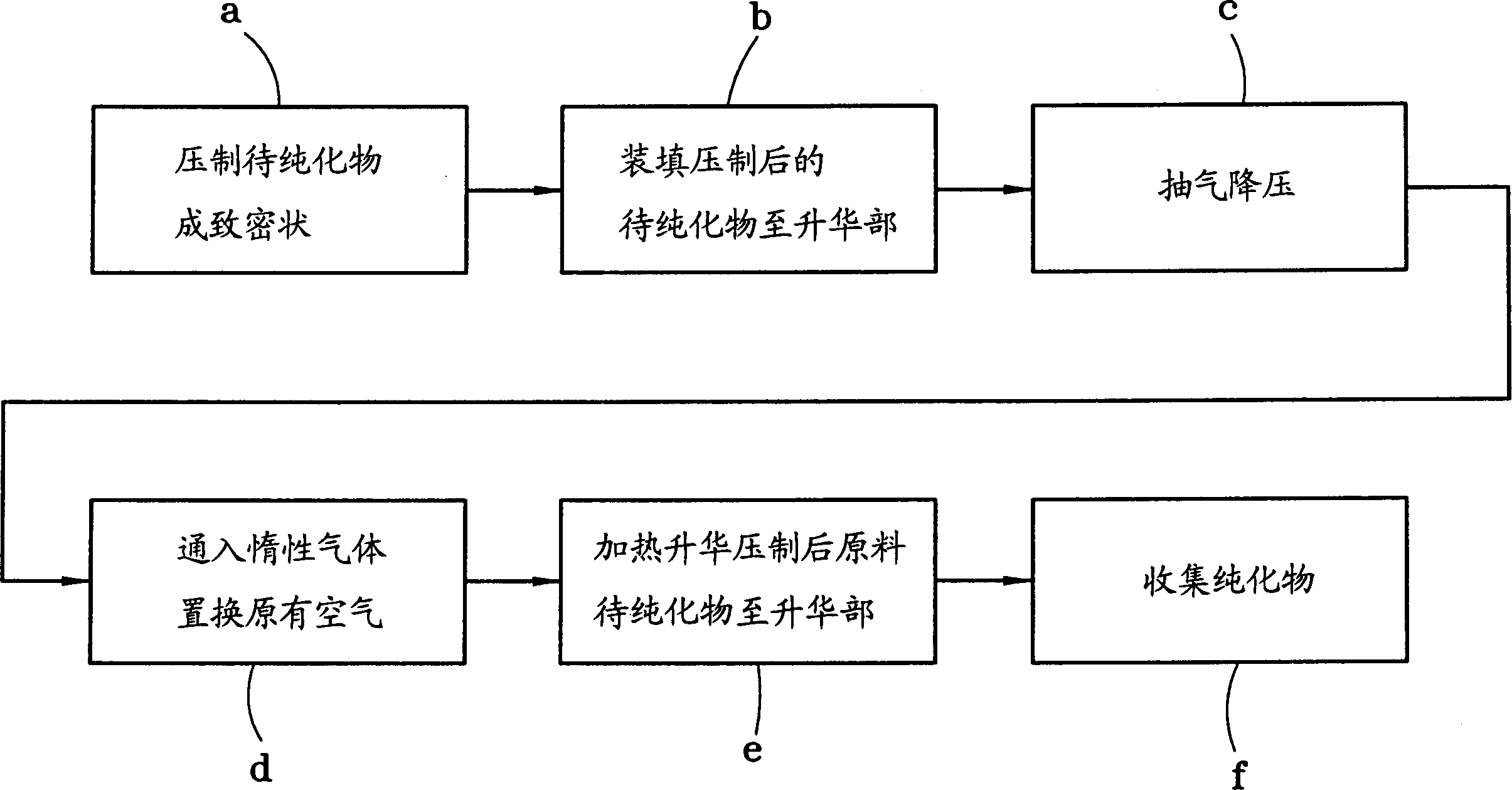

[0011] see figure 1 As shown, it is a schematic diagram of the manufacturing process of the improved sublimation purification method of the present invention, as shown in the figure: firstly, the powdery substance to be purified 10 is compressed into a compact shape through a predetermined pressure, temperature and time, and the to-be-purified substance 10 after pressing is completed. When the purified product 10 is sublimated and purified, since the compressed product 10 to be purified is more uniform and compact than the powder, it can hold more mass of the product to be purified 10 per unit volume, that is, the carrier 211 of the sublimation part 21 is carried in one sublimation. The quality of some objects to be purified 10 is greatly increased, and because the objects to be purified 10 after pressing are uniform and dense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com