Method gel-chromatographic analysis of terephthalates compounds

A technology of terephthalic acid and ester compounds, applied in the direction of analyzing materials, material separation, measuring devices, etc., can solve the problem of low product solubility, and achieve the effect of easy repeatability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

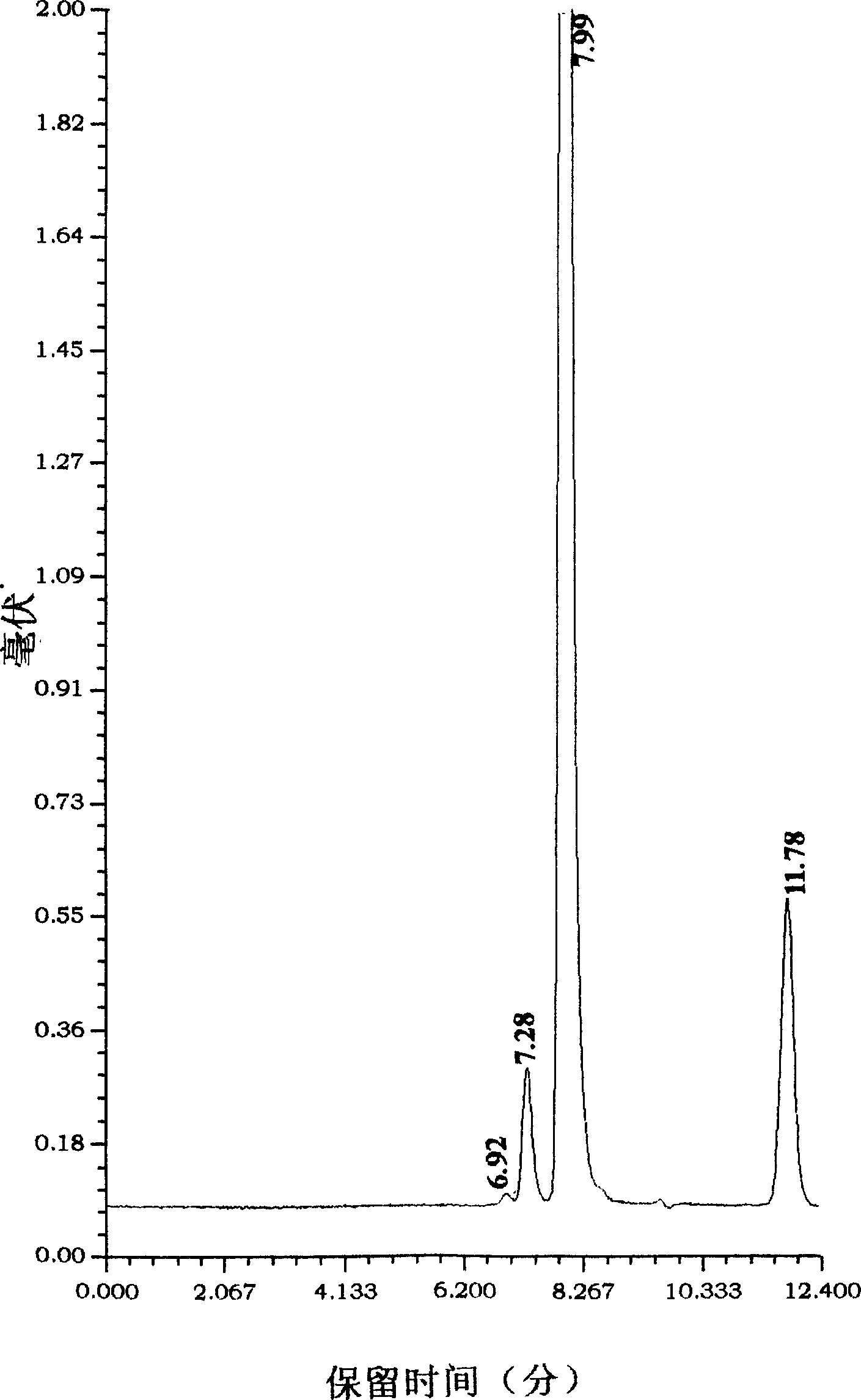

[0012] The mensuration of embodiment 1 diethylene glycol terephthalate (BHET)

[0013] ①Determination purpose In conjunction with the basic research of supercritical extraction of polyethylene terephthalate (PET), the purity of the chromatographic standard sample diethylene terephthalate (BHET) needs to be determined first.

[0014] ② Source of pure reagent: TCI-EP Terephthalic Acid, manufactured by Tokyo Chemical Industry Co., Ltd., the purity content is not indicated.

[0015] ③Analysis conditions

[0016] Analytical instrument: Shimadzu LC-3A high-performance liquid chromatography; detector: UVD-2 ultraviolet detector; wavelength: 254nm; chromatographic column: GPC-801, inner diameter 8.0mm, length 300mm (produced by Shimadzu Corporation of Japan)

[0017] Experimental conditions Mobile phase: tetrahydrofuran; flow rate: 0.9ml / min; column temperature: 19°C; sample concentration: 0.066g / 100ml; injection volume: 3 microliters.

[0018] Calculation method: Since the reagent ...

Embodiment 2

[0020] Embodiment 2 Determination of pure reagent-dimethyl terephthalate (DMT)

[0021] ① Determining the purpose of polyethylene terephthalate (PET), polytrimethylene terephthalate (PTT) and their polymerized plastics under supercritical extraction, the main monomer generated is terephthalate For dimethyl formate (DMT), a pure reagent must be used as a reference for the chromatographic qualification and quantification of this monomer. Before using this pure reagent, it is necessary to measure the purity of this pure sample.

[0022] ② Source of pure reagent Dimethyl terephthalate (Dimethyl terephthalate, DMT), produced by Aldrich Chem Corp Inc.

[0023] ③Analysis conditions

[0024] Analytical instrument: Shimadzu LC-3A high-performance liquid chromatography; detector: UVD-2 ultraviolet detector; wavelength: 254nm; chromatographic column: GPC-801, inner diameter 8.0mm, length 300mm (produced by Shimadzu Corporation of Japan)

[0025] Experimental conditions Mobile phase: te...

Embodiment 3

[0028] Example 3 Selection of synthetic dipropylene glycol terephthalate (BHPT)

[0029] ① Determining the purpose of polyethylene terephthalate (PTT) in supercritical depolymerization, according to the reaction mechanism, there should be by-product dipropylene glycol terephthalate (BHPT). When testing, terephthalic acid Dipropylene glycol ester (BHPT) standard reagent, however, there is no such supply in the domestic and foreign markets at present, for this reason, need self research, synthesis. The method can measure the products synthesized by the process and carry out evaluation.

[0030] ② Sample source: Sample 1 and Sample 2 are obtained by reacting polyethylene terephthalate (PET) with propylene glycol at 240°C.

[0031] ③Analysis conditions

[0032] Analytical instrument: Shimadzu LC-3A high-performance liquid chromatography; detector: UVD-2 ultraviolet detector; wavelength: 254nm; chromatographic column: GPC-801, inner diameter 8.0mm, length 300mm (manufactured by S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com