Method for manufacturing optical elements

A technology of optical components and manufacturing methods, applied in optics, polarizing components, nonlinear optics, etc., capable of solving problems such as irregular peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

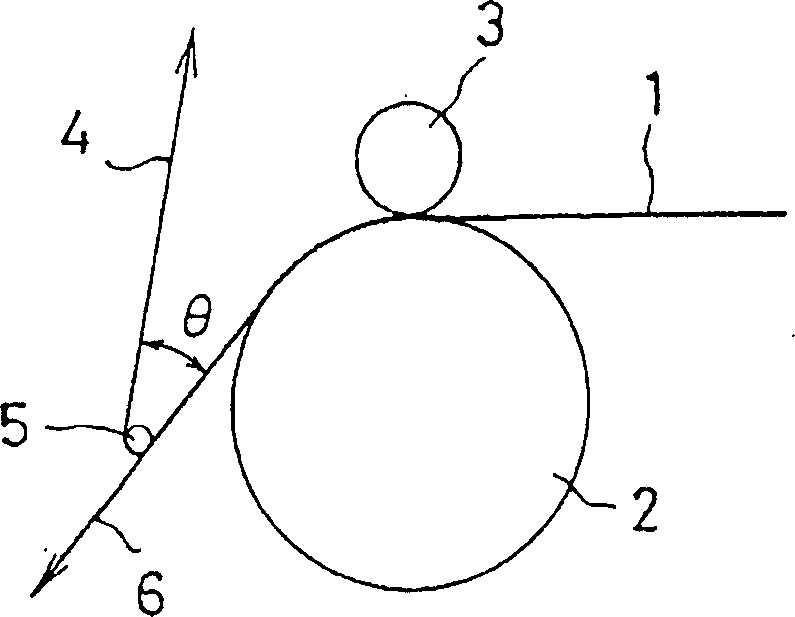

Image

Examples

Embodiment

[0039] Hereinafter, the present invention will be specifically described based on examples, but the present invention is not limited by these examples.

[0040] Various analytical methods used in Reference Examples and Examples are as follows.

[0041] (1) Determination of optical parameters

[0042] The optical parameters of the twist angle and retardation (Δn·d) of the liquid crystal film were measured by polarized light analysis method. (Δn: birefringence constant, d: thickness of the liquid crystal layer of the liquid crystal film; unit nm)

[0043] (2) Determination of logarithmic viscosity

[0044] The measurement was carried out in a phenol / tetrachloroethane (60 / 40 weight ratio) mixed solvent at 30° C. using an Ubbelode viscometer.

[0045] (3) Determination of liquid crystal polymer composition

[0046] Dissolve the liquid crystalline polyester in deuterated chloroform, using a 400MHz 1 H-NMR (JNM-GX400 manufactured by JEOL Ltd.) was measured to determine the comp...

reference example 1

[0048] Synthesize the liquid crystal polymer substance (logarithmic viscosity=0.22dl / g, Tg=61 ℃) of formula (1) and (R)-3-methylhexane-1,6-bis containing formula (2) Optically active liquid crystal polymer substance (logarithmic viscosity=0.17dl / g) of alcohol unit.

[0049] The synthesis of these polymer materials is carried out by reacting acid chlorides corresponding to dicarboxylic acid units with diol compounds in the presence of triethylamine in o-dichlorobenzene solvent.

[0050] The liquid crystalline polymer solution-1 was prepared by dissolving 18.1 g of the obtained liquid crystalline polymer of formula (1) and 1.9 g of the liquid crystalline polymer mixture of formula (2) in 80 g of N-methylpyrrolidone.

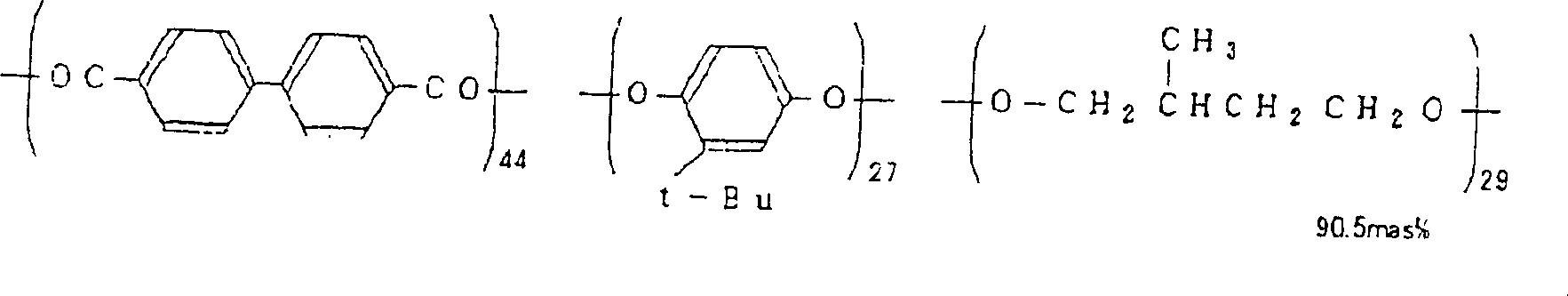

[0051] Formula 1)

[0052]

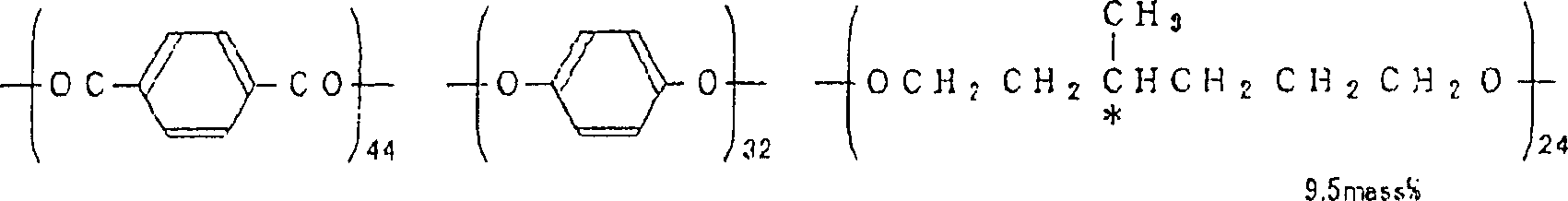

[0053] Formula (2)

[0054]

[0055] * Optically active carbon

reference example 2

[0057] Using 80mmol terephthalic acid, 23mmol pimelic acid, 55mmol hydroquinone diacetate, 50mmol isopropyl catechol diacetate and sodium acetate as a catalyst, polymerized at 280°C for 2 hours under nitrogen atmosphere, Polymerization was carried out at 300° C. for 2 hours to obtain a liquid crystalline polymer substance of formula (3).

[0058] Then, the obtained liquid crystal polymer substance was dissolved in tetrachloroethane, and then reprecipitated with methanol to obtain 26 g of a purified liquid crystal polymer substance. The logarithmic viscosity of this liquid crystal polymer substance is 0.31dl / g. As a result of DSC measurement and polarizing microscope observation, the liquid crystal phase is a nematic phase, and the low temperature portion lower than the liquid crystal phase is a glass phase without a crystal phase. , Tg is 117°C.

[0059] 15 g of this liquid crystal polymer substance was dissolved in 85 g of tetrachloroethane to prepare a liquid crystal phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com